Mud blocks have been used for construction since ancient times, predating the invention of traditional clay bricks. Rammed Earth Blocks (REBs), adobe walls, Cob Blocks, and stabilized mud blocks are examples of mud-based construction techniques that have been used in various regions. Although their usage has declined with the advent of modern construction materials and technology, mudblocks remain cost-effective and environmentally friendly.

In recent years, the Southeast region of India has recognized the potential of mud blocks and has revitalized their usage by incorporating improvements in their production and construction techniques. So this article is on stabilized mud blocks.

What are The Stabilized Mud Blocks (SMBs)?

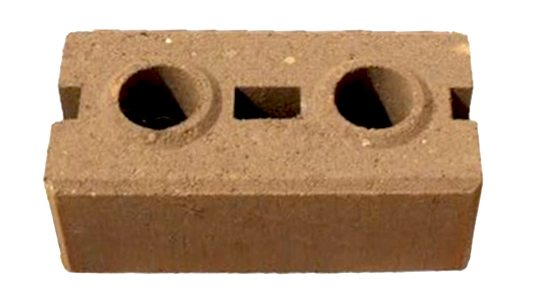

Stabilized Mud Blocks (SMBs) are mud blocks for a building material primarily made from selected soil or earth. Unlike other types of mud blocks, stabilized mud bock is made by compressing a mixture of selected earth, cement, and water. The compressed blocks are then allowed to dry in the sun, without the need for firing or baking, and are used for construction purposes.

They are considered to be a sustainable and eco-friendly alternative to traditional building materials like fired bricks and concrete blocks, as they are made from locally available materials. It does not require large amounts of energy for the production of SMBs. They are also relatively low-cost and can be produced on-site as the mud is readily available. Thus, Stabilized Mud Blocks are a popular choice for construction in rural and remote areas.

Types of Stabilized Mud Blocks

Some of the most common types of stabilized mud blocks are:

- Compressed Stabilized Earth Blocks (CSEBs): These are made by compressing a mixture of soil, sand, and stabilizers such as cement, lime, or fly ash, and are used for load-bearing walls and foundations.

- Interlocking Stabilized Soil Blocks (ISSBs): These are similar to CSEBs, but they have a special interlocking design that allows them to be dry-stacked without the need for mortar. They are commonly used for walls and partitions.

Also, read: What Is Adobe Wall?

Material Composition of SMBs

Although it is a mud block, Stabilized mud blocks are made by mixing suitable soil, sand, cement, and water in varying proportions, depending on the soil type and its properties. The mixture is then compressed into blocks using a hydraulic or manual press. The exact proportions of the materials used may vary based on the blocks’ desired strength, durability, and other properties. However, the mix commonly comprises 70-80% soil and 20-30% stabilizer (cement or lime).

The general composition of the materials used to make stabilized mud blocks:

- Soil: The soil used for SMBs is usually clayey or silty soil, which provides good binding properties when mixed with sand and cement. The soil should be free of organic matter, rocks, and other debris that can weaken the blocks.

- Sand: Sand is added to the mixture to improve the workability and reduce the shrinkage of the blocks. The sand used should be clean and well-graded, with a particle size of about 2mm.

- Cement: Cement is added to the mixture to improve the strength and durability of the blocks. Usually, ordinary Portland cement or lime pozzolana mixture is used, but other types of cement can also be used.

- Water: Water is added to the mixture to form a workable paste that can be compressed into blocks. The amount of water used should be carefully controlled to ensure that the blocks are not too wet or too dry.

Also, read: Ordinary Portland Cement: Properties, Composition, Manufacturing And Uses

Physical Properties:

The properties of SMBs may vary depending upon the purpose, usage, region building code and atmospheric exposure. However, here are some common physical properties of stabilized mud blocks:

- Compressive strength: The compressive strength of SMBs typically ranges from 1.5 to 10 MPa, depending on the soil type and stabilizing agent used. This means that it can support a certain amount of weight without breaking or deforming. As per IS: 3495 ( Part I )-1976, the minimum average compressive strength of:

- Class 20 should have 20kgf/cm2 = 1.96 MPa.

- Class 30 should have 30kgf/cm2 =2.94199 MPa.

- Water absorption: They can absorb a certain amount of water, but their water absorption rate is lower than traditional fired bricks. This property makes it more resistant to water damage. The average water absorption shall not be more than 15 per cent by weight immersion in cold water for 24 hours.

- Density: The density is generally between 1,800 and 2,200 kg/m³, which is similar to that of traditional fired bricks.

- Weathering: When tested for weathering as described in IS1725 – 1982, the maximum loss of weight shall not exceed 5 per cent.

- Thermal conductivity: They have a low thermal conductivity, which means they are good at insulating heat. This property can help keep buildings cool in hot climates and warm in cold climates.

- Durability: It can be durable if they are correctly made and cured. They can resist weathering and erosion and can last for many years.

- Fire resistance: They are generally not very resistant to fire, but their fire resistance can be improved by adding fire retardants to the soil mix.

Advantages:

- Stabilized mud blocks are a sustainable and eco-friendly alternative to traditional building materials like fired bricks and concrete blocks.

- They are made from locally available materials and do not require large amounts of energy to produce, which makes them a low-cost option for construction in rural and remote areas.

- They have good thermal insulation properties and can help to reduce energy consumption for heating and cooling.

- They have good fire resistance and can withstand extreme temperatures.

- They have good sound insulation properties and can reduce noise transmission.

Also, read: 10 Effective Thermal Insulation Materials for Building

Disadvantages:

- Stabilized mud blocks may not be suitable for use in areas with high rainfall, as they can absorb moisture and become weak over time.

- They may not be suitable for use in seismic zones, as they may not have the necessary strength and ductility to withstand earthquakes.

- They may require additional surface treatment or plastering to make them more resistant to weathering and erosion.

- They may require skilled labour for production and construction, which can increase the cost of the project.

Also, read: 4 Types of Seismic Bands for Masonry Structure: Horizontal bands, Advantages and Disadvantages

Uses of Stabilized Mud Blocks:

Stabilized mud blocks (SMBs) are sustainable and cost-effective building material that has a wide range of uses and some of the uses include:

- Wall construction: Can be used for constructing load-bearing or non-load-bearing walls in buildings. The blocks have good thermal insulation properties, which help to keep the interior of the building cool in hot weather and warm in cold weather.

- Flooring: Also, it can be used for constructing floors in buildings. They have good compressive strength and can withstand heavy loads.

- Paving: These are suitable for paving walkways, driveways, and other areas. They are durable and can withstand heavy foot and vehicle traffic.

- Landscaping: SMBs can be used for constructing retaining walls, garden walls, boundary walls, and other landscaping features. They can be easily moulded into different shapes and sizes to suit the design requirements.

- Infrastructure projects: Stabilized Mud Blocks can also be used for constructing small bridges, culverts, and other infrastructure projects in rural areas. They are easy to transport and can be manufactured on-site using locally available materials.

Also, read: Confined Masonry Construction Details

FAQs:

Q: What are Stabilized Mud Blocks (SMBs)?

Answer: Stabilized Mud Blocks are construction blocks made by stabilizing compressed earth or mud with the help of stabilizers such as cement or lime. This process enhances the strength and durability of the blocks.

Q: How are Stabilized Mud Blocks made?

Answer: SMBs are typically made by mixing soil, a small amount of cement or lime, and water. The mixture is compressed into blocks using a hydraulic press or manually operated presses. The blocks are then cured before use.

Q: What is the ratio of soil to stabilizer in Stabilized Mud Blocks?

Answer: The exact ratio can vary, but a common mix is around 70-80% soil and 20-30% stabilizer (cement or lime). The ratio may be adjusted based on soil properties and specific project requirements.

Q: Can Stabilized Mud Blocks be used for load-bearing walls?

Answer: Yes, Stabilized Mud Blocks can be used for load-bearing walls in low-rise buildings. However, structural design and engineering considerations are essential to ensure the blocks can bear the intended loads.

Q: Can Stabilized Mud Blocks be plastered or rendered?

Answer: Yes, SMBs can be plastered or rendered to improve their appearance and provide additional protection against weathering.

Q: Can stabilised Mud Blocks be used for load-bearing walls?

Answer: Yes, Stabilized Mud Blocks can used in all categories of load-bearing buildings (as per IS 4326: 1993 category A to E) provided at least a proper masonry mortar is applied and all arrangement prescribed in the code is provided if 3 storied load bearing building is constructed.

References:

- The stabilised mud block. (2020, May 2). Architales. https://architales.org/malhar-in-the-making/the-stabilised-mud-block/

- Bureau of Indian Standards. (1982). Specification for soil-based blocks used in general building construction (First Revision). IS 1725-1982. Bureau of Indian Standards. https://law.resource.org/pub/in/bis/S03/is.1725.1982.pdf

![]()