Portland cement is a versatile building material that has been used for centuries in the construction of buildings, bridges, roads and other structures. Cement is a fine powder made from a mixture of limestone, clay and other minerals that are heated to high temperatures in a kiln. Portland cement comes in a variety of colours, including grey, white, and colour variations. This article will focus on white Portland cement, its properties, uses, advantages and disadvantages.

What is White Portland Cement?

White Portland cement also known as white cement or white Ordinary Portland cement (WOPC) is a type of Portland cement used to give concrete and other building materials a pure white finish. It is made from the same basic ingredients as grey Portland cement (Ordinary Portland Cement), but certain elements have been added to give it a whiter colour. The main difference between white and grey Portland cement is the amount of iron oxide, which gives the grey cement its unique colour.

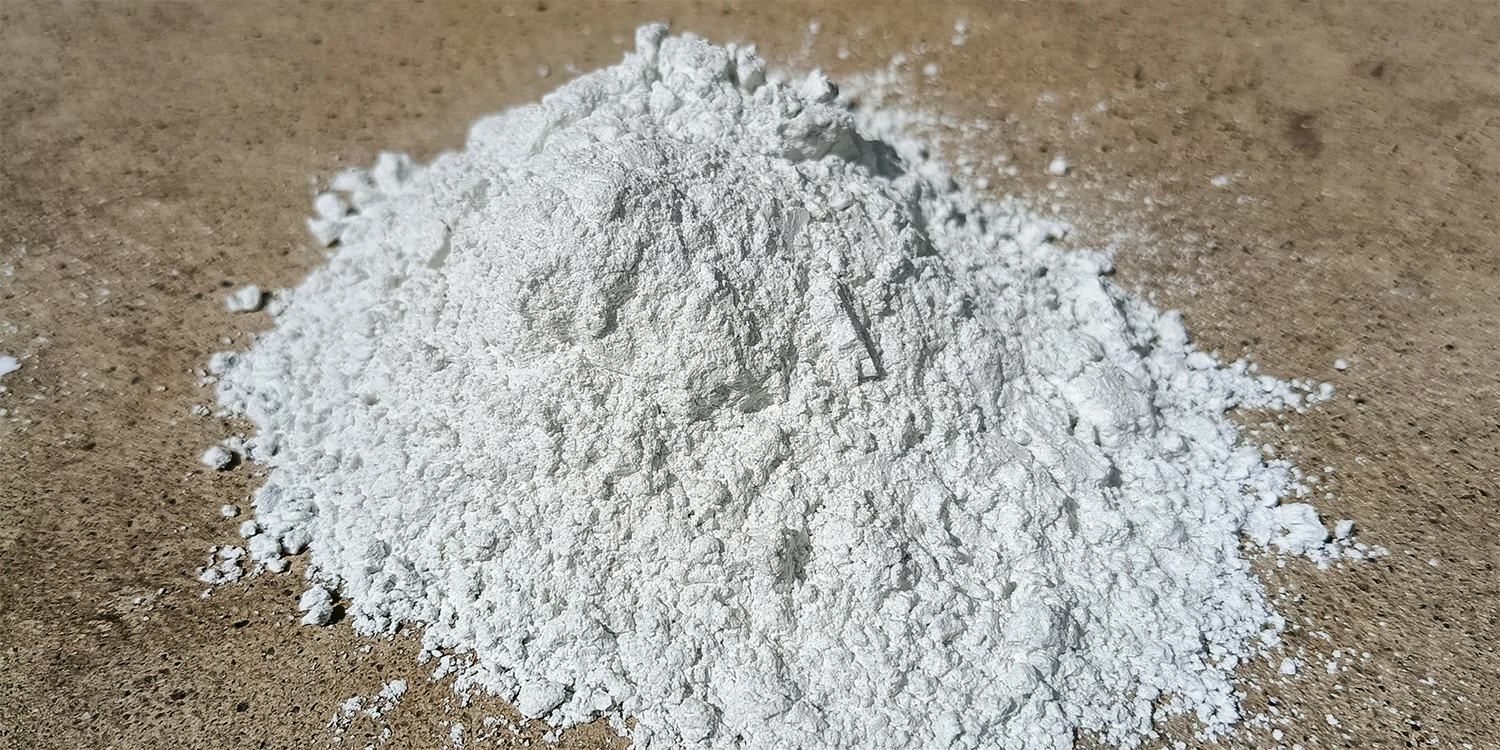

Raw materials containing small amounts of iron and manganese oxides are used to produce white Portland cement. These raw materials are finely ground, mixed and heated to a temperature of approximately 1,450 degrees Celsius. The resulting product is a fine white powder, particularly for terrazzo flooring, stucco, and architectural concrete (Mehta, M. 2017).

White Portland cement is commonly manufactured in Type I or Type III variations, which exhibit similar characteristics to grey Type I and Type III Portland cement, respectively. Both white and grey Portland cement are typically packaged in bags for easy distribution.

Also, read: Ordinary Portland Cement: Properties, Composition, Manufacturing and Uses

Properties of White Portland Cement:

It has properties similar to grey Portland cement, like high strength, durability, water and chemical resistance. However, white cement also has some unique properties that make it suitable for certain applications. Some of the properties of white cement are:

- Colour: The main property of white cement is its colour, which is pure white. It is used to create a clean, bright appearance on concrete, stucco, and other construction materials.

- Fineness: It is finely ground to produce a powder that is much finer than OPC. It has a specific surface area of around 300-450m2/kg, which makes it an excellent choice for applications that require a smooth surface finish.

- Setting Time: The setting time is similar to that of grey Portland cement, but it may take slightly longer to set in certain conditions.

- Strength: Has similar strength properties to OPC, with an early strength of around 24-72 hours and a final strength of 28 days. Its compressive strength ranges from 40-60 MPa, which makes it suitable for various structural applications.

Also, read: Types of Cement | Grade of Cement | 10 Types

Composition:

White Portland cement is similar in chemical composition to regular Portland cement (OPC) but differs in colour and the presence of certain elements. The main raw materials used to manufacture such cement are limestone, silica and gypsum. These raw materials are ground into fine powders and mixed in the required proportions to form a uniform mixture. The chemical composition of the cement is as follows:

- Calcium oxide (CaO) – 65-70%

- Silica (SiO2) – 20-25%

- Alumina (Al2O3) – 3-8%

- Iron oxide (Fe2O3) – 0.5-2.5%

- Magnesium oxide (MgO) – 0.5-4%

- Sulfur trioxide (SO3) – 1-3%

- Alkalis (Na2O and K2O) – 0.5-1.5%

- Loss on ignition (LOI) – 0-5%

The primary difference between white cement and OPC is the lower iron and manganese content in the former, which gives it a white colour. It is manufactured using a higher-quality limestone with low iron content and lower quantities of other impurities. The production process of white ordinary Portland cement is similar to that of OPC, but the clinker is cooled rapidly and finely ground to produce a white powder.

Applications of White Cement:

It has a wide range of applications, including:

- Architectural concrete: White Portland cement is an ideal material for architectural concrete applications, such as precast panels, tiles, and countertops. The white colour and fine texture make it perfect for creating a smooth and polished finish.

- Decorative Concrete: It is commonly used in decorative concrete applications, such as stamped concrete, polished concrete, and exposed aggregate concrete. It creates a bright, clean, and uniform finish that is ideal for high-end residential and commercial projects.

- Precast Concrete: White cement is also used in precast concrete products, such as countertops, sinks, and architectural elements. It provides a consistent, high-quality finish that is easy to work with and customize.

- Masonry: White Portland cement is used to create white mortar for brick and stone masonry applications. It provides a uniform, clean appearance that complements the natural beauty of the masonry materials.

- Tile Adhesives: White Portland cement is used as a binder in tile adhesives to create a white, durable, and water-resistant bond between tiles and substrates.

Advantages of White Cement:

- Aesthetic Appeal: The main advantage of white Portland cement is its aesthetic appeal. It creates a pure white finish that is ideal for high-end projects and architectural designs.

- Versatility: Such cement is a versatile material that can be used in a wide range of applications, including decorative concrete, precast concrete, masonry, and tile adhesives.

- Durability: White Portland cement is a durable material that is resistant to water, chemicals, and other environmental factors.

- Compatibility: It is compatible with other construction materials, including aggregates, admixtures, and pigments.

Disadvantages of White Cement:

Though white cement has several advantages, it also has some disadvantages that must be considered before selecting it for a particular application. Here are some of the major disadvantages of white Portland cement:

- Cost: White Portland cement is more expensive than ordinary Portland cement due to the higher cost of raw materials and the additional processing required to achieve its white colour. This makes it less cost-effective for some applications.

- Availability: It is not as readily available as OPC, which may make it challenging to source for some projects. It may also require longer lead times to procure the material, which could delay project timelines.

- Staining: White Portland cement is more susceptible to staining than OPC, particularly when exposed to water or other substances that can cause discolouration. This can be a significant concern for applications that require a pristine white appearance.

- Limited use: Typically it is used for specialized applications that require a white colour, which limits its versatility. It may not be the best choice for general-purpose applications where its unique properties are not required.

- Curing time: White Portland cement requires more extended curing times than OPC, which may result in longer project timelines. This can be particularly challenging for applications where a fast turnaround time is required.

FAQs:

Q: What is white Portland cement, and how is it different from ordinary Portland cement?

Ans: White Portland cement is a type of cement that is similar in composition to ordinary Portland cement (OPC) but has a lower iron and manganese content, giving it a white colour. It is used for specialized applications where white colour is desired, such as architectural and decorative concrete.

Q: What are the primary raw materials used to produce white Portland cement?

Ans: The primary raw materials used to produce white Portland cement are limestone, silica, and gypsum. These materials are ground into a fine powder and mixed in the desired proportion to form a homogeneous mixture.

Q: What are the disadvantages of using white Portland cement?

Ans: The disadvantages of using white Portland cement include its higher cost, limited availability, susceptibility to staining, and longer curing times.

Q: How do you store white Portland cement?

Ans: White Portland cement should be stored in a dry, cool, and well-ventilated area to prevent moisture absorption and caking. It should be kept away from direct sunlight and sources of heat.

Q: Is white Portland cement environmentally friendly?

Ans: White Portland cement is not considered environmentally friendly due to the high energy consumption required for its production and the greenhouse gas emissions associated with cement production. However, there are efforts to reduce the environmental impact of cement production through the use of alternative materials and production methods.

References:

- White Portland cement. (2023, February 11). In Wikipedia. https://en.wikipedia.org/wiki/White_Portland_cement

- Britannica, T. Editors of Encyclopaedia (2023, February 23). portland cement. Encyclopedia Britannica. https://www.britannica.com/technology/portland-cement

- Mehta, M., Scarborough, W., & Armpriest, D. (2017). Building constructions: Principles, materials, and systems. Pearson Education, Inc.

![]()