Concrete Slump Test

The concrete slump test is a standard test in civil engineering and construction to measure the consistency or workability of fresh concrete. It is conducted on-site and is a simple and quick procedure to assess the properties of the concrete mix. A slump test must be conducted on every batch of concrete throughout the construction project. Thus, this can ensure consistency and monitor the workability of the concrete mix.

Different types of construction projects may require different slump ranges. For example, high-slump concrete is often used in applications where the concrete needs to flow easily, such as in pumped concrete for large structures. Low-slump or zero-slump concrete may be used in applications where the concrete needs to be more rigid, such as in vertical columns.

Principal:

The slump test is generally carried out in the field as well as in the laboratory to determine the ‘consistency’ and workability of concrete. The consistency indicates the degree of fluidity or mobility and the nature of concrete. The slum is classified as a true slump. Fresh concrete is placed into a mould resembling a frustum of a cone. Upon lifting the cone vertically, the distance the concrete settles, known as the slump, serves as an indicator of the concrete’s consistency. The slump test is suitable for assessing the consistency of concrete within a specific range, typically between 10 mm and 210 mm.

| Slump | Nature of Concrete mix |

|---|---|

| No Slump | Stiff and extra stiff mix |

| From 10mm to 30mm | Poorly mobile mix |

| From 40mm to 150mm | Mobile mix |

| Over 150mm | Cast mix |

Factors Influencing Concrete Slump Test:

The following factors influence concrete Slump value:

- Quality of Fine aggregate, Coarse aggregate, its texture, grading size, moisture content, and shape of it.

- Also, affects the water-cement (w/c) ratio of concrete.

- Air Content of Concrete and Void ratio of concrete.

- Use of various types of admixtures such as Superplasticizer, Plasticizer admixture, and the sequence of their mixing.

- Time is also an important factor for concrete mixing.

Also, read: Concrete Batching Method

Apparatus:

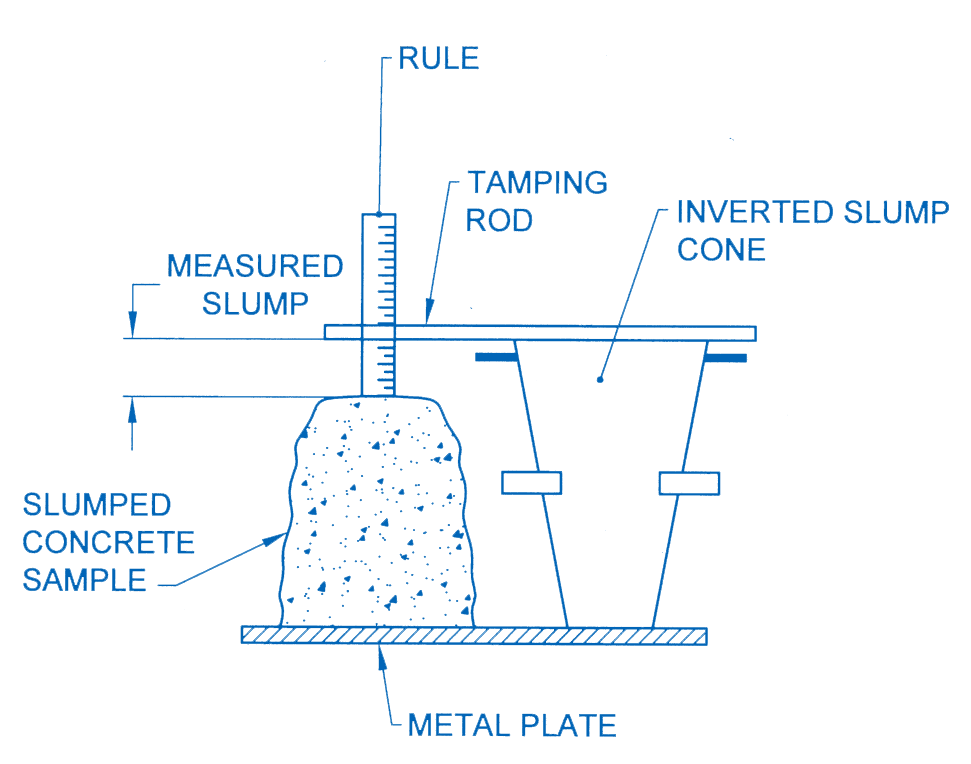

The apparatus used for a slump test are relatively simple and include the following:

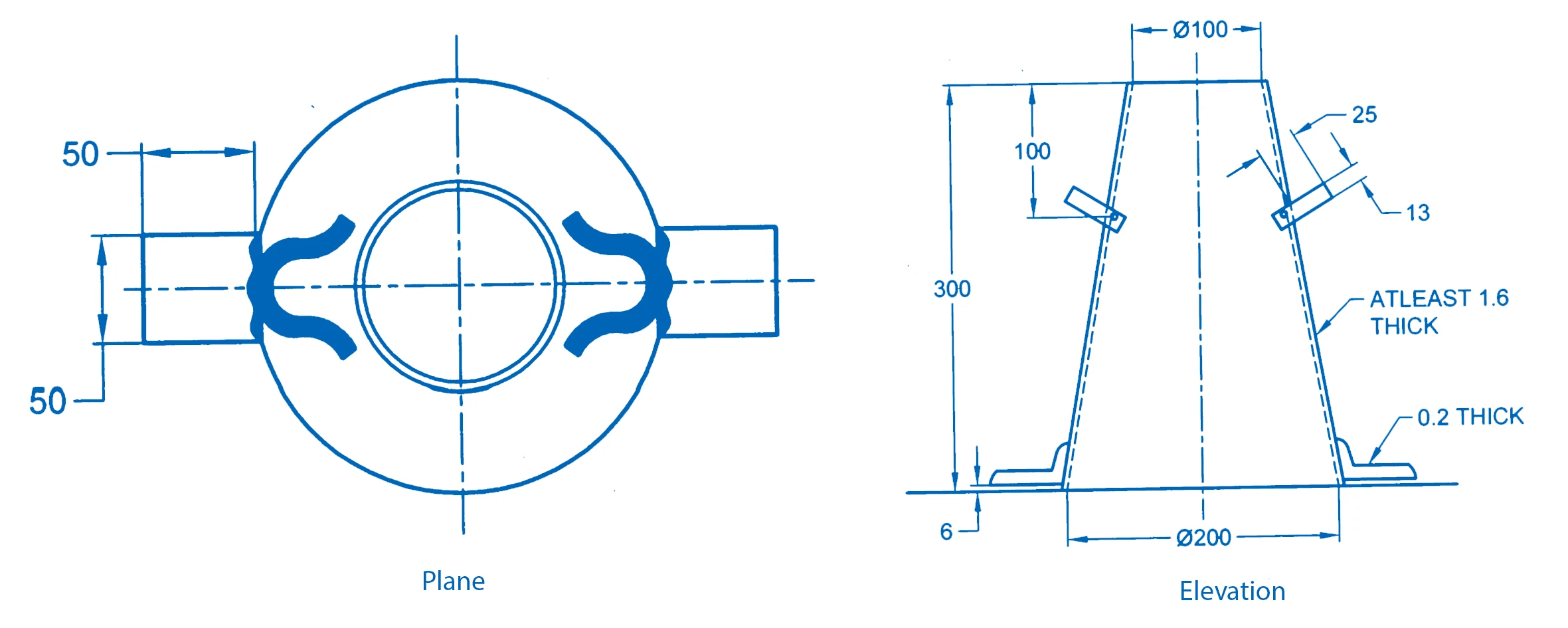

- Mould (Slump Cone): Made of metal with a smooth internal surface and free from dents. The mould shall be in the form of a hollow frustum of a cone and shall have the following internal dimensions:

- Diameter of base: 200 ± 2 mm

- Diameter of top: 100 ± 2 mm

- Height: 300 ± 2 mm

- Tamping Rod: Used for compacting the concrete in the slump test. The temping rod is made of steel with a circular cross-section of 16 mm (5/8 inches) and a length of approximately 600 mm (24 inches) with round ends.

- Base Plate: A smooth, rigid, flat, and non-absorbent surface on which the slump cone is placed during the test.

- Measuring Scale or Rule: A measuring device, usually a ruler, to measure the slump of the concrete. It should be graduated from 0 mm to 300 mm.

- Trowel or Scoop: A hand tool used for pouring and smoothing the concrete surface after the test.

- Bucket or Remixing Tray: It is used for transporting the concrete to the test location from the concrete plan. It should be fabricated from a non-absorbent material, not readily attacked by cement paste. It should be an adequate size for performing re-mixing of concrete.

- Stopwatch or Timer: To measure the time taken for the concrete to slump. The time should measure accurately to 1 second.

- Personal Protective Equipment (PPE): Safety gear such as gloves and safety glasses, as appropriate, to protect against potential hazards.

Also, read: Importance Of Personal Protective Equipment (PPE) In Construction Zones

Slump Test Procedure:

- Keep the slump cone on the base plate and hold it firmly with hands.

- The Slump cone is filled with fresh concrete in three layers, each approximately equal to one-third of the height after compaction. The tamping should be with 25 strokes with the tamping rod on each layer.

- The strokes must be distributed uniformly over the cross-section and penetration to the bottom layers from second layers onwards and completion depth for the first layer.

- Following the compaction of the final layer, excess concrete is smoothed and brought level with the top of the mould using a trowel. This ensures that the slump cone is filled and presents a flat and even surface for accurate measurement.

- Remove all the concrete spilled around the cone.

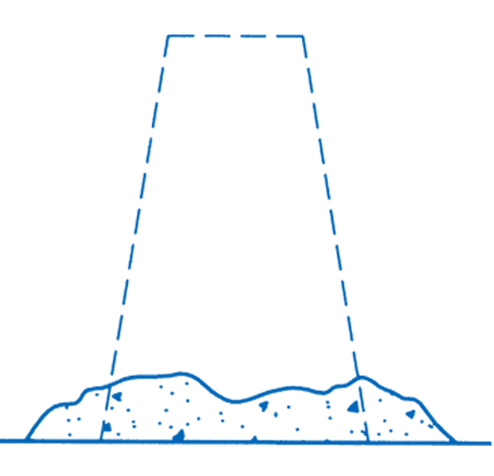

- Then slump cone is removed immediately by raising it vertically and slowly. This allows the concrete to subside and the slump is measured immediately by measuring the difference between the height of the mound and the highest point on the concrete.

- The slump measured must be recorded in millimetres.

- According to IS 1199 (Part 2): 2015, the recommended procedure mandates that the entire operation, starting from the initiation of filling to the removal of the mould, should be conducted without any interruption. Furthermore, this entire process is expected to be completed within a time frame of 180 seconds.

Also, read: What is Concrete Mix Design?

Test Results:

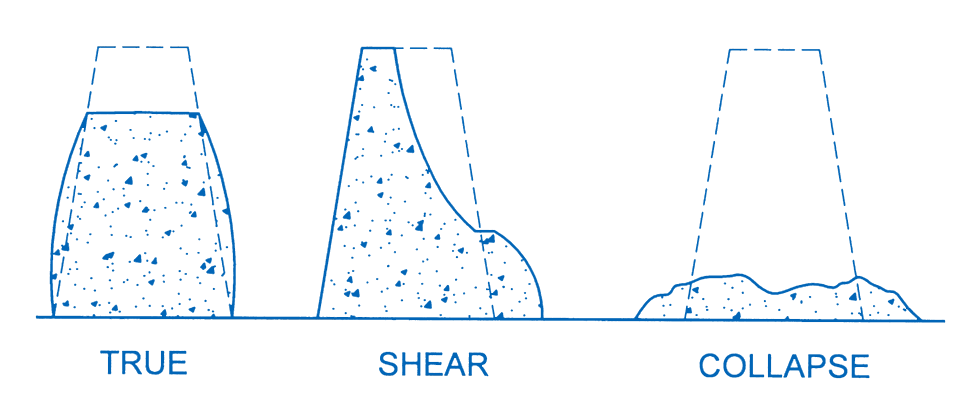

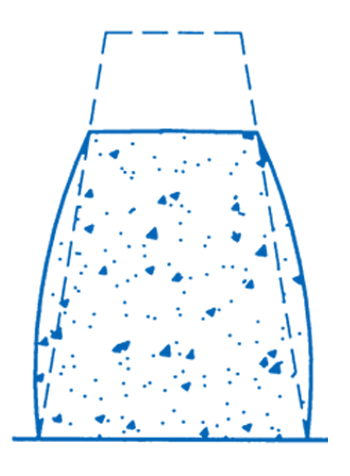

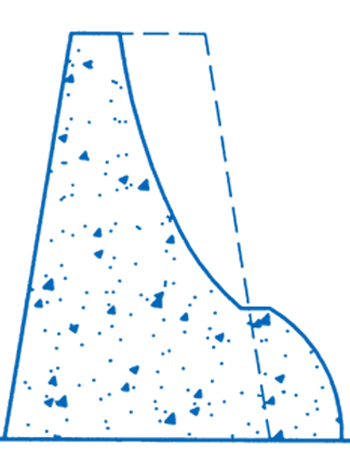

The test is valid only if it yields a true slump. In this state, the concrete remains intact and symmetrical. If a specimen shows collapses and shear as shown in the figure below the entire process should be redone by taking another sample.

Types of Slump

| True | Shear | Collapse |

|---|---|---|

| In a true slump, the concrete settles uniformly, maintaining its shape to a significant extent. | During a shear slump, the upper section of the concrete shears away and shifts laterally. | In a collapse slump, the concrete undergoes a total collapse, losing its form entirely. |

|  |  |

Test Report:

The test report shall include;

- Identification of the test sample;

- Location of performance of test;

- Date of the test;

- Type of slump – true/shear;e) measured true slump, to the nearest 10 mm;

Recommended slumps of concrete

| No. | Types of Concrete | Slump |

|---|---|---|

| 1. | Concrete for road construction | 20 to 40 mm |

| 2. | Beams and slabs | 50 to 100 mm |

| 3. | Normal RCC work | 80 to 150 mm |

| 4. | Mass concrete | 25 to 50mm |

| 5. | Concrete to be vibrated | 10 to 25 mm |

| 6. | Impermeable work | 75 to 120 m |

Also, read: What is The Water-Cement Ratio?: Calculation and Value of Water Cement Ratio.

Limitations Of The Slump Test

The slump test is applicable to concrete with medium to low workability, falling within the range of 5 to 260 mm. However, the test is not effective in assessing workability differences in stiff mixes with zero slump or in wet mixes resulting in a collapse slump. Additionally, its applicability is restricted to concrete composed of aggregates smaller than 38 mm (1.5 inches).

International Standard For Slump Test

The concrete Slump test is governed by various international codes, each of which provides specific testing standards. These standards outline the methods and equipment used to assess the consistency of fresh concrete through the Slump test. To ensure acceptance and reliability, it is crucial to adhere strictly to these standards when conducting the Slump test for concrete. The following are the standards governing the concrete Slump test.

- ISO 4109: This is the original international standard for the slump test, published in 1980. It specifies a cone height of 300 mm, a bottom diameter of 200 mm, and a top diameter of 100 mm. The cone is filled with concrete in three layers, each of which is tamped 25 times. The slump is then measured as the difference between the original height of the cone and the height of the concrete after it has slumped.

- ASTM C 143: This is the American Society for Testing and Materials (ASTM) standard for the slump test. It is very similar to ISO 4109, but it specifies that the cone should be lifted vertically after it has been filled with concrete.

- BS EN 12350-2: This is the European standard for the slump test. It is also very similar to ISO 4109, but it specifies that the concrete should be placed in the cone in two layers, each of which is tamped 35 times.

- IS 1199 (Part 2): 2018: In India the code guides the slump test.

| Feature | ISO 4109 | ASTM C 143 | BS/EN 12350-2 | IS 1199: 2015 |

|---|---|---|---|---|

| Cone height | 300 mm | 300 mm | 300 mm | 300 mm |

| Bottom diameter | 200 mm | 200 mm | 200 mm | 200 mm |

| Filling layers | 3 | 3 | 3 | 3 |

| Tamping strokes per layer | 25 | 25 | 25 | 25 |

| Lifting method | Vertical | Vertical | Vertical | Vertical |

| Slump measurement | Difference between original and final height | Difference between original and final height | Difference between original and final height | Difference between original and final height |

Also, read: Factor Affecting Workability of Concrete

FAQs:

Q: When is a slump test performed on concrete?

Ans: A slump test is typically performed on fresh concrete during the early stages of construction, specifically when the concrete is in its plastic or workable state.

Q: How many layers of concrete is required in slump test?

Ans: In the standard slump test procedure, the fresh concrete is compacted in three layers within the slump cone. After each layer is placed, it is compacted using a tamping rod before adding the next layer. This process ensures proper compaction and removes any potential voids within the concrete sample.

Q: What is the true slump?

Ans: The true slump of a concrete refers to the condition in which the concrete mix, when subjected to the slump test, settles uniformly without breaking or shearing.

Q: What are the types of slump in a concrete?

Ans: There are three types of slump namely, truse, shear and collapse slump that are observed while consduction slump test.

References:

- Bureau of Indian Standards (2018). IS 1199 (Part 2): 2018. Fresh Concrete — Methods of Sampling, Testing and Analysis. https://standardsbis.bsbedge.com/BIS_SearchStandard.aspx?Standard_Number=IS+1199&id=0

- Standard test method for slump of Hydraulic-Cement concrete. (n.d.). https://www.astm.org/c0143_c0143m-12.html

- Wikipedia contributors. (2023, November 30). Concrete slump test. Wikipedia. https://en.wikipedia.org/wiki/Concrete_slump_test

![]()