In the ever-evolving world of construction, engineers and architects are constantly seeking innovative solutions to enhance the efficiency, safety, and aesthetics of buildings. One such modern approach gaining popularity in the construction industry is the use of flat slab systems. Flat slab construction is a structural design technique that offers numerous advantages, making it an attractive choice for a variety of building projects. There are many types of slab constructed. So, in this article, we will be looking into flat slabs, their types, advantages and disadvantages with their suitable application.

What is a Flat slab?

A flat slab is a type of reinforced concrete slab that is supported directly by columns without the use of beams. That means it does not rest on the beam on any part of its sides but rests directly on columns with or without drops. Unlike traditional slabs, which have beams spanning between columns to distribute the load, flat slabs are characterized by a flat soffit (underside) and a simple and continuous surface.

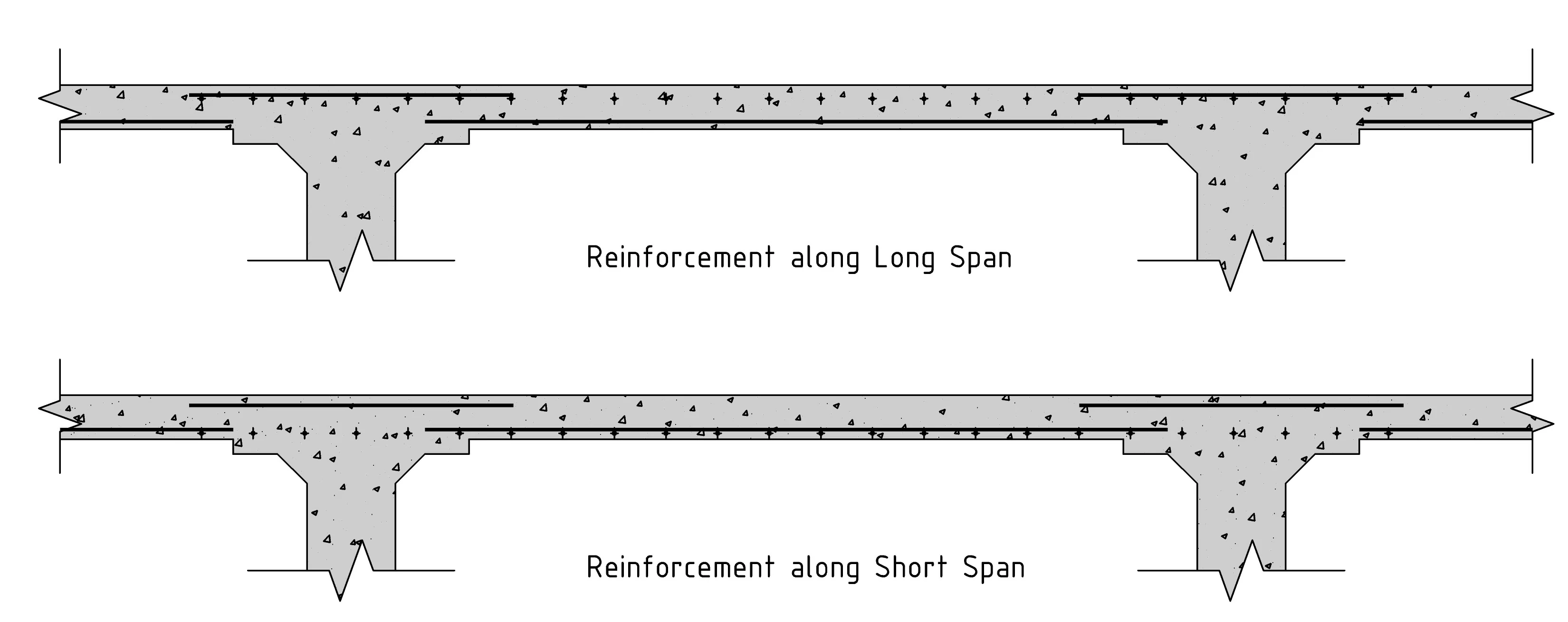

It is typically designed as a two-way slab, with a thickness greater than that of the slab supported by a beam. Such slabs are referred to as two-way column-supported slabs. According to IS 456:2000, the flat slab must have a minimum thickness of 125 mm.

The construction of this type of slab is usually integral to columns. The flat slab may be solid or may have recesses formed on the soffit comprised of a series of ribs in two directions. The recesses may be formed by removable or permanent filler blocks.

The primary advantage of flat slabs is their simplicity and ease of construction. By eliminating beams, construction becomes faster and more straightforward. This can result in cost savings and faster project completion. They are often used in buildings where flexibility in the floor plan is desired, as the absence of beams allows for more open and flexible layouts.

However, such slabs may require thicker slabs or additional reinforcement to compensate for the lack of beams and to ensure that they can support the required loads.

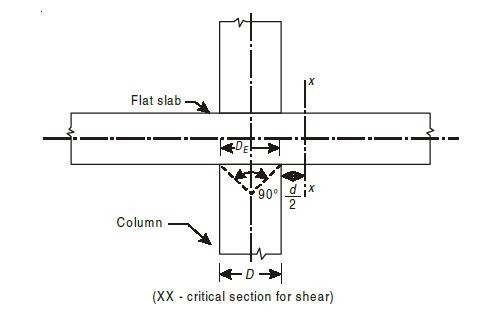

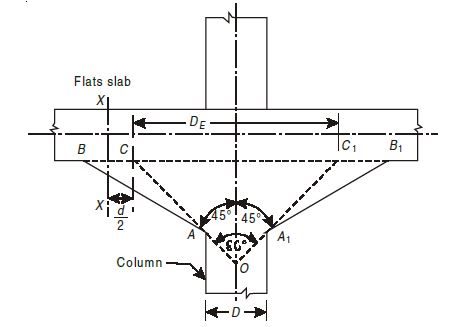

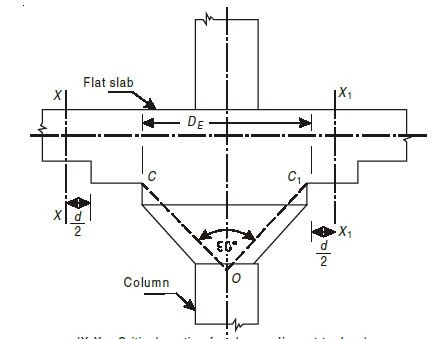

Critical failure for a flat slab is punching shear failure or two-way shear failure. The critical section for shear shall be at half the distance (d / 2) from the face of a column or drop panel or column capital, perpendicular to the plane of the slab where (d) is the effective depth of the section.

Elements of Flat Slabs

- Column Heads:

The column heads or the column capitals are provided on the top of the columns to increase the capacity of the slab to resist two-way shear.

- Drops:

Drops are commonly provided in flat slabs to decrease the shear stresses around the column supports. This is because the shear forces are concentrated near the columns, and the thicker drop section provides additional area to resist these forces.

These drops should ideally have a rectangular plan shape, with a length in each direction not falling below one-third of the corresponding panel length. In the case of exterior panels, the width of drops, measured from the centerline of the columns and perpendicular to the non-continuous edge, should be half the width of the drops specified for interior panels.

The drop thickness, which refers to the additional thickness beyond the overall depth of the slab, should be a minimum of 0.25 times the slab thickness. When drops are incorporated, they not only serve the purpose of reducing shear stresses around column supports but also lead to a reduction in the area of reinforcement for negative bending moments at these supports.

- Panels:

In flat slabs, panels are defined as the sections of the slab enclosed on all four sides by the centerlines of the columns.

Types of Flat Slabs

Given below are the details of different types of flat slab construction. They are classified into the following categories:-

- Simple/Typical flat slab

- Flat slab containing drop panels

- Flat slab containing column heads

- Flat slab containing both drop panels and column heads

1. Simple/Typical Flat Slab

This type of slab as shown in Fig.2. is built where the span is small and the load is lighter comparatively. This type of slab is sometimes termed a flat plate.

2. Flat Slab Containing Drop Panels

The slabs with drops and columns with column heads are constructed where the large shear forces also develop along with large bending moments. The thickness of the slab around the column is increased to resist the shear. This thickened portion or increased thickness of slab is known as the drop panel, or simply the drop. Initially, this is developed for heavy loads and large spans and typically uses the flared column capital and often the thickened slab around the column or a drop panel.

Application of Drop Panel: –

- Increase of share strength in slab

- The negative moment capacity of the slab also increases

- This tightens the slab and thus decreases the deflection

3. Flat slab Containing Column Heads

Slabs without drops and with column heads are constructed where large bending moments develop around the columns. The top of the column is enlarged in the shape of an inverted frustum, referred to as the column head or column capital. Fig.3. is an illustration containing a column head.

Application of Column Heads: –

- Significantly increase of share strength in the slab.

- It minimizes the moment with the curtailment of the clear or effective span.

The columns, column heads, slabs and drop panels are the various elements in this type of slab.

Also, read: Column Failure: Causes | Types | Prevention

4. Flat Slab With Both Drop Panels and Column Heads

Fig.4. shows the slab design, which incorporates both drop panels and column heads, significant shear forces and bending moments are expected. To withstand these forces, the thickness of the slab is augmented around the columns to resist shear, often referred to as diagonal tension. This reinforced and thickened section around the column is commonly known as the drop panel or simply the drop.

Advantages of Flat Slab Construction

They have the advantage of being practically flat (plain) from the underside. Thus, the advantages are as follows:-

Enhanced Flexibility in Architectural Design:

The construction of such a slab allows for greater flexibility in architectural design. The absence of beams provides more freedom in arranging interior spaces, enabling architects to design modern and open floor plans without the constraints imposed by traditional structural systems.

Reduced Construction Time:

The simplified construction process of flat slabs often leads to reduced construction time. With fewer components and a straightforward installation process, projects employing such slab systems can be completed more efficiently compared to traditional methods. This can translate to cost savings and earlier project completion.

Cost Efficiency:

One of the most important advantages is the cost efficiency of constructing a flat slab. This is by the elimination of beams and the reduction in the quantity of materials required to contribute to cost efficiency in flat slab construction. The simplicity of the design minimizes the need for complex formwork and labour-intensive processes, resulting in a more economical solution for building structures.

Increased Headroom:

The absence of beams creates a flat ceiling surface, maximizing the available headroom in a structure. This is particularly advantageous in spaces where a higher ceiling is desired for aesthetic or functional reasons, such as in commercial buildings, offices, and residential spaces.

Adaptability to High-Rise Buildings:

Flat slab systems are well-suited for high-rise buildings. Their inherent structural efficiency and the ability to distribute loads evenly make them a viable option for tall structures, providing stability and strength while maintaining design flexibility.

Disadvantages of Flat Slab Construction

While flat slab construction offers various advantages, it is important to acknowledge that, like any structural system, it comes with its own set of disadvantages. Understanding these limitations is crucial for making informed decisions in the design and construction process. Here are some notable disadvantages of flat slab construction:

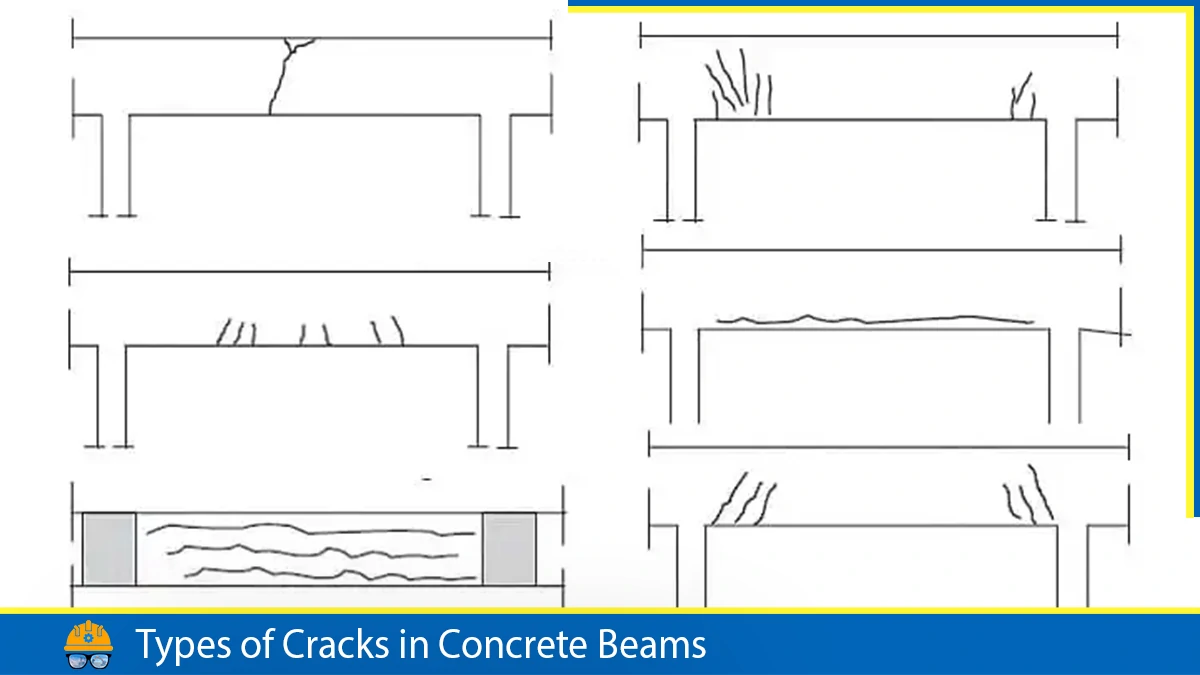

Reduced Strength in Shear:

One of the primary concerns with flat slab systems is their reduced capacity to resist shear forces compared to traditional systems with beams. This can result in a lower overall load-carrying capacity and may necessitate additional reinforcement or design modifications to address shear-related issues.

Increased Deflections:

Flat slabs may experience greater deflections, particularly in the middle span of the slab. This can lead to aesthetic concerns, as well as potential challenges in accommodating services such as plumbing and electrical installations. Designers may need to incorporate measures to mitigate deflection-related issues.

Punching Shear:

Punching shear is a critical consideration in flat slab design. The concentrated loads at column-slab connections can lead to punching shear failure if not adequately addressed. Proper reinforcement detailing and additional design measures may be required to ensure the structural integrity of these connections.

Limited Span Lengths:

Such slab systems are not always suitable for long-span structures. Traditional beam-and-slab systems or other structural solutions may be preferred for projects with specific span length requirements.

Vulnerability to Fire Resistance:

The flat nature of the slab can impact the fire resistance of the structure. Adequate fire protection measures must be implemented to ensure the safety and integrity of the building in the event of a fire.

Also, read: Fire-Resistant Building Construction

Application of Flat Slab:

lat slabs find application in a variety of building projects due to their architectural flexibility, cost efficiency, and other advantageous features. Here are some common applications of flat slabs in the construction industry:

Commercial Buildings:

Flat slabs are frequently used in commercial structures such as office buildings, shopping malls, and retail centers. The open floor plan and increased headroom provided by flat slabs contribute to a versatile and modern design, accommodating various commercial needs.

Residential Buildings:

In residential construction, flat slabs are employed for apartment buildings, condominiums, and residential towers. The design flexibility allows for spacious and aesthetically pleasing interiors, meeting the demands of contemporary living spaces.

Hotels and Hospitality:

The adaptability of flat slabs makes them suitable for hotels and hospitality projects. The absence of beams enables efficient space planning for lobbies, dining areas, and guest rooms, contributing to a welcoming and functional environment.

Parking Structures:

Flat slabs are used in the construction of parking garages. The simplicity of the design facilitates efficient use of space, and the absence of beams makes it easier to navigate and park within the structure.

Also, read: What Are Concrete Column Kickers? | Column Starter

FAQs:

Q: What is a flat slab?

Ans: A flat slab is a type of slab that does not rest on the beam on any part of its sides. This type of slab rests directly on columns with or without drops. A flat slab is usually designed as a two-way slab. The thickness of the slab is thicker than that of the slab resting on the beam.

Q: What should be the thickness of flat slabs?

Ans: The minimum thickness of a flat slab is 125mm thick. The maximum thickness of the slab is usually up to 200 mm thick.

Q: Why are column Heads provided to flat slabs?

Ans: Column heads are provided to flat slabs when the bending moment around the column is maximum.

Q: What is the role of column capitals in flat slab construction?

Ans: Column capitals, also known as drop panels, are thickened regions around column heads that enhance the load distribution and improve the structural performance of flat slabs.

Q: How is punching shear addressed in flat slab design?

Ans: Punching shear is addressed through proper reinforcement detailing, using shear reinforcement, and ensuring adequate slab thickness around column-slab connections.

Q: Can flat slab construction be used in seismic regions?

Ans: Yes, flat slab construction can be adapted for seismic design. Proper engineering and detailing, including the use of shear walls and appropriate reinforcement, are crucial to ensure the structure’s seismic resilience.

References:

- Bureau of Indian Standards. (2000). IS 456:2000 – Code of Practice for Plain and Reinforced Concrete. New Delhi, India: Bureau of Indian Standards.https://law.resource.org/pub/in/bis/S03/is.456.2000.pdf

- Punima, Dr. B. C. (2006). Building Construction. Luxmi Publication (P) Limited. Ltd.https://books.google.nr/books?id=_kAvTMzKGhAC&printsec=copyright#v=onepage&q&f=false

- Krishna, R. N. (2022). Reinforced Concrete Design: IS :456-2000 Principles and Practice. New Age International Private Limited.

![]()