What is a Micrometer?

A micrometer, also spelt micrometre, is a unit of length in the metric system, denoted by the symbol “\( \mu m \)” (pronounced “micron”). One micrometer is equal to one-millionth of a meter, or \( 1\times10^{-6} \) meters. It is often used to express dimensions on the scale of microscopic objects, such as cells, bacteria, or wavelengths of light.

What is a Micrometer Screw Gauge?

A micrometer screw gauge, commonly known as a micrometre, is a precise measuring instrument used to measure small dimensions with a high degree of accuracy. It is used for measuring linear dimensions such as diameter, thickness and lengths of the solid bodies. It consists of a calibrated screw that is rotated to advance or retract a spindle, allowing for extremely fine adjustments in length measurements. Micrometers are widely used in various fields, such as engineering, machining, and quality control, where precise measurements are essential.

Micrometer is a mechanical device which is used to measure precisely; it consists of a C-shaped frame with a movable jaw operated by an integral screw. In the field of Civil Engineering, it can be used to measure the thickness of sheet metal, steel section, steel plates, diameter of wire, etc. It is also known as a micrometre screw gauge. It consists of a circular scale and a pitch scale. The schematic picture below shows the typical illustration of the screw gauge.

Parts of Micrometer Screw Gauge

The main components of screw gauge include:

- Frame: The main body or frame of the micrometer provides the structural support for the instrument.

- Anvil and Spindle: It has a stationary anvil (fixed reference point) and a movable spindle. The object to be measured is placed between the anvil and the spindle.

- Screw: The heart of the micrometer is a precisely machined screw, which is turned by the user. The rotation of the screw causes the spindle to move toward or away from the anvil, allowing for precise adjustments.

- Thimble: The thimble is a rotating sleeve that sits on top of the frame. It is marked with a scale, typically graduated in millimeters or inches, and is used to measure the axial movement of the spindle.

- Sleeve: The sleeve is connected to the thimble and can be rotated for fine adjustments. It typically has markings corresponding to fractions of a millimeter or inch. It is also called the Barrer or Stock.

- Ratchet Stop: Many micrometers have a ratchet stop mechanism that prevents over-tightening and ensures consistent pressure is applied during measurements.

Principal of Screw Gauge

It works with the principle of the screw. By rotating the screw, we get the linear movement of the circular scale.

Pitch

The pitch is defined as the distance moved by the screw on the sleeve over the number of rotations made by the circular scale.

\( Pitch\;=\;\frac{Distance\;moved\;by\;the\;screw\;}{No\;of\;rotations} \)

Least Count

The least count of the screw gauge is defined as the distance moved by the tip of the screw when turned through one division of the head scale.

The formula to calculate the least count of a micrometer screw gauge is given by:

\( Least\;Count\;=\;\frac{Pitch\;of\;the\;screw}{Number\;of\;divisions\;on\;the\;circular\;scale} \)

- Pitch of the screw: It is the distance moved by the spindle per one complete rotation of the thimble. It is usually given in millimeters (mm).

- Number of divisions on the circular scale: This refers to the number of equally spaced divisions on the circular scale or thimble.

For example, if the pitch of the screw is 0.5 mm and the circular scale has 100 divisions, the least count would be \( \frac{0.5}{100}=0.005 \) mm or 5 micrometers.

A smaller least count indicates a more precise measuring instrument because it can make finer measurements. Micrometers are designed to have a very small least count, allowing for highly accurate measurements in applications where precision is critical.

Total Reading

The total reading is the sum of the reading on the main scale and the reading on the circular scale reading. i.e.Total Reading = Main Scale reading + Circular Scale Reading

Circular Scale Reading = Least Count X Coinciding division of the circular scale with the baseline

Zero Error

When the zero of the circular scale does not coincide with the baseline at the initial state even after the spindle and stud touch each other before conducting any measurement is called a “Zero Error” of the screw gauge. Zero error can be either positive or negative.

Positive Zero Error

The condition is said to be a positive zero error when the zero of the circular scale is below the baseline before the actual measurement. As shown in the Figure 2.

Positive zero error = Coinciding division of Circular scale with baseline X Least Count

Thus, the correct reading will be Reading – Positive Zero error

Also, read: Distance Measurement With Measuring Tape: Corrections & Errors

Negative Zero Error

The condition is said to be a negative zero error when the zero of the circular scale is above the baseline before the actual measurement. As shown in the Figure 3.

Negative zero error = Coinciding division of Circular scale with baseline X Least Count

Thus, the correct reading will be Reading – Negative Zero error

Reading Measurement in Micrometer

- Select the suitable micrometre size depending on the size of the workpieces.

- Check the zero error of the device.

- Place the workpiece in between the anvil and spindle, and rotate the thimble to make the spindle touch the workpieces.

- Rotate until the ratchet starts slipping over the thimble.

- Now take the reading on the main scale and note it down.

- Take the thimble reading which by where the thimble coincides with the baseline on the sleeve or main scale and note it down.

- Calculate the actual reading by adjusting the zero error as the formula provided above.

Usage of Micrometer or in the field of engineering:

While the screw gauge finds extensive application in engineering, construction, manufacturing units, industries, and various scientific studies, its practical applications in civil engineering and auditing are outlined below:

- For measuring the diameter of chain-link wire mesh.

- For reconfirming the thickness of the glass panel and roofing cover materials.

- For checking the thickness of steel plates & flats, steel sections or structural steel.

- For measuring the diameter of nuts and bolts, Revit.

- For auditing and inspection of the materials brought and installed at the site.

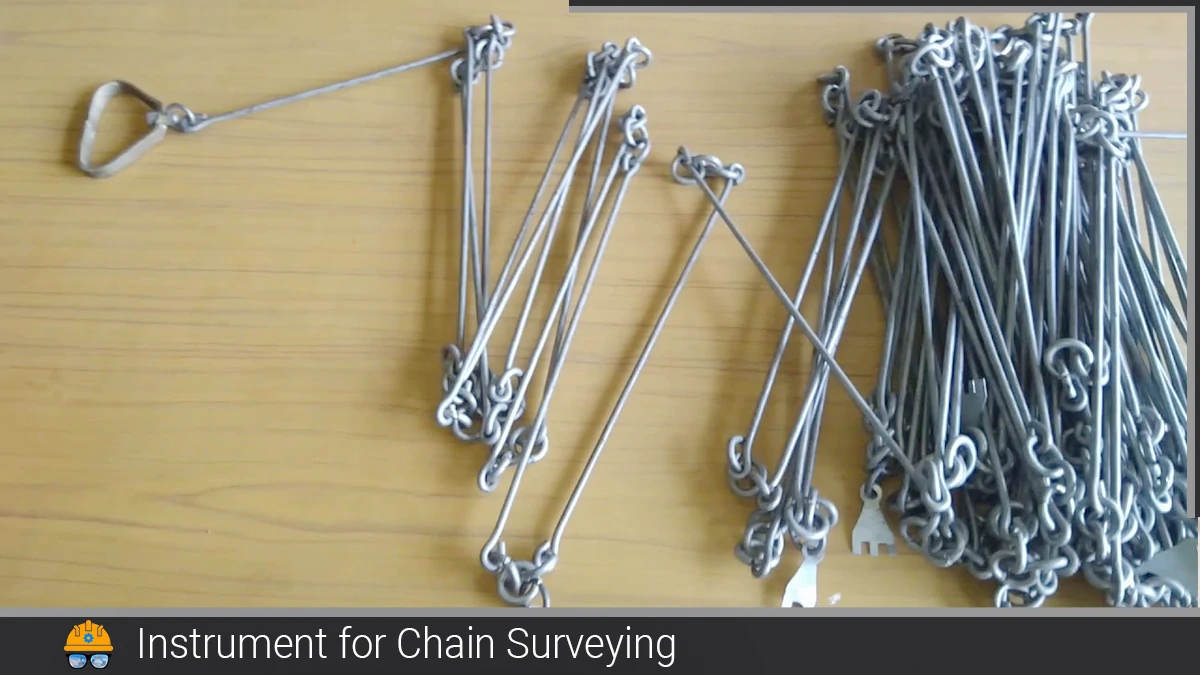

Also, read: Instrument For Chain Surveying

References:

- Wikipedia contributors. (2023, November 4). Micrometer (device). Wikipedia. https://en.wikipedia.org/wiki/Micrometer_(device)

- Britannica, T. Editors of Encyclopaedia (2023, November 6). micrometre. Encyclopedia Britannica. https://www.britannica.com/science/micrometre

![]()