Protecting the masonry wall by plastering is a good choice but can also be done with pointing at a lesser cost. The looks of masonry works can be elevated if pointing is done. However, it is the choice of the individual homeowner and Architecture or designer. This article is about pointing in masonry works covering its pros and cons, and comparing the plaster and pointing.

What is Pointing?

Pointing in masonry works refers to finishing mortar joints in stone or brick masonry construction. Essentially, it involves filling joints that are 10-20mm deep with a higher-quality mortar that has been meticulously crafted to conform to the desired shape. It is crucial to note that this technique is suitable for employment in both lime and cement mortar joints.

Madan Mehta defines pointing as “Raking an existing (generally defective) masonry mortar joint to a sufficient depth and then finishing it with new mortar” in his book Building Construction, Principles, Materials and Systems. Here, word pointing also means, repairing the damaged or deteriorated mortar from the joints and replacing it with fresh mortar.

Exposed masonry’s mortar joints are vulnerable to weathering. This leads to water infiltration facilitated by wind and pollution, causing erosion of mortar and adding more infiltration of moister or water to the masonry wall. Uneven settlement in a building’s foundation can cause mortar to crack. As the building settles into the ground, stress is transferred to the structure, resulting in cracked and peeling mortar joints. This, in turn, allows more moisture to enter the deteriorating mortar joints.

This is typically done using a trowel to carefully pack the new mortar into the joint, ensuring that it is flush with the surface of the wall. The new mortar is then smoothed and tooled to match the surrounding joints, creating a uniform and cohesive appearance. Proper pointing helps to protect the masonry wall from moisture infiltration, erosion, and other forms of damage and can extend its lifespan significantly.

Materials for Pointing Work

Mortar is used for pointing work. Usually, Portland Cement such as Ordinary Portland Cement, White Portland Cement or Pozzolina Portland Cement is used for preparing cement mortar for the job. Fat lime is ground with sand or Surkhi for lime mortar. The mortar of lime and cement is used in the following mix proportion.

- Lime mortar of 1:2 ( 1 lime: 2 sand or Surkhi)

- Cement mortar of 1:3 ( 1 cement : 3 sand)

Purpose of Pointing

Understanding and knowing the purpose of pointing on the surface of masonry walls is crucial. Thus following three points are the main purpose of pointing.

- Improves the aesthetics of the masonry building by enhancing the mortar joints with different shapes.

- Repairs the damaged mortar joints of walls and other masonry structures thus preventing them from failure.

- Smoothing the masonry joints through pointing provides effective protection against exposure to water, air, dust, and more.

Prosses Involved in Pointing

Preparation of Surface

Surface preparation for pointing for old and new works are as follows

a) New works:

All the joints are raked down to a depth of 20mm while the mortar is still soft. The surface and joints are then cleaned and thoroughly wetter.

b) Old works:

All loose pointing and superfluous mortar on the surface and in the joints are removed. The joints and surface are cleaned, and then thoroughly wetted.

Method of Pointing

Upon surface preparation and joint cleaning and wetting as aforementioned, carefully insert mortar into the joints using a small trowel. Ensure the mortar is pressed to achieve optimal contact between the old and new mortar in the joint. Be mindful not to cover face edges in the case of ashlar and brickwork of superior quality. The pointing surface should be kept moist for a minimum of one week or until set after application.

Comparison between plastering and pointing

Masonry walls can be protected through either plastering or pointing techniques, which differ significantly in their approach. The comparison between plastering and pointing is tabulated below.

| Plastering | Pointing |

|---|---|

| It provides a smooth surface. | It is applied to the entire surface. |

| Whitewashing or colour washing are ruled out | It provides a smooth surface. |

| It conceals defective workmanship in the masonry construction. | It is used to expose the beauty of well-built masonry work. |

| It provides a base for applying white/colour washing | Whitewashing or colour washing is ruled out |

Types of Pointing

There are 8 different types of Pointing such as:

Flush Pointing

Flush pointing is one of the easiest and most used among all the pointing types for its durability and ease of maintenance. It does not provide any space for the accumulation of dust or water making it easy to maintain, though, it does not provide a good appearance.

In this method of pointing, mortar is pressed in the raked joint and flushed off its edge with a masonry unit by using a towel. The excess mortars are neatly trimmed off with a trimmer.

Rubbed, Keyed or Grooved Pointing

This pointing is a modification of flush pointing. The mortar is filled in the same manner as that of flush pointing. The concave groove is created by inserting and removing a metal rod when the concrete is still fresh. It gives a better appearance than flush pointing.

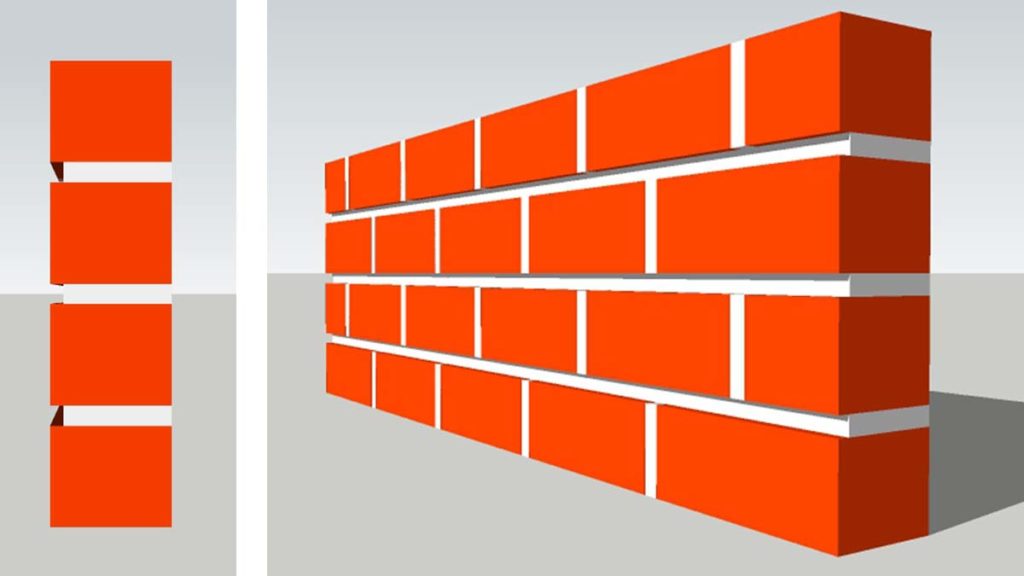

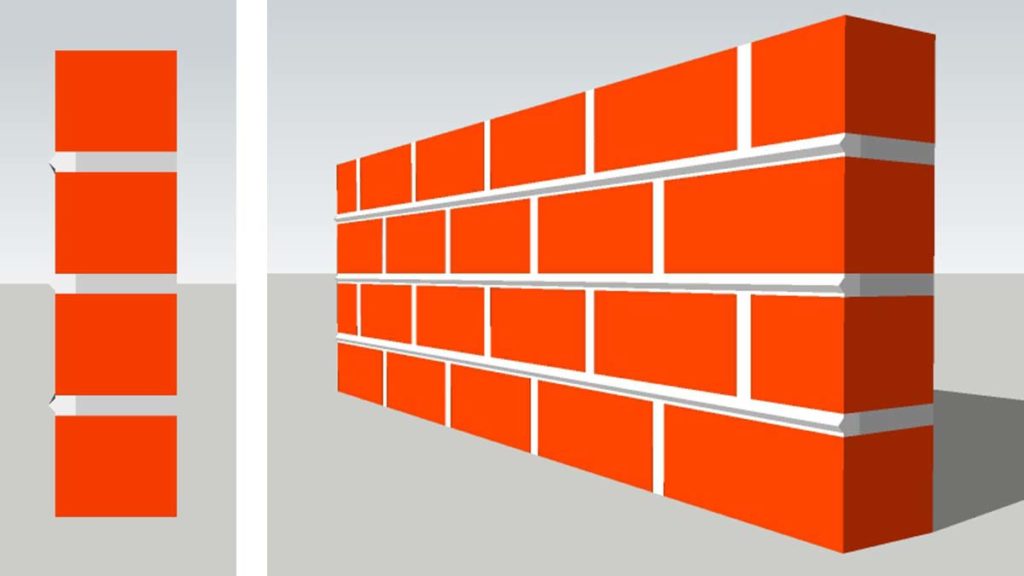

Recessed Pointing

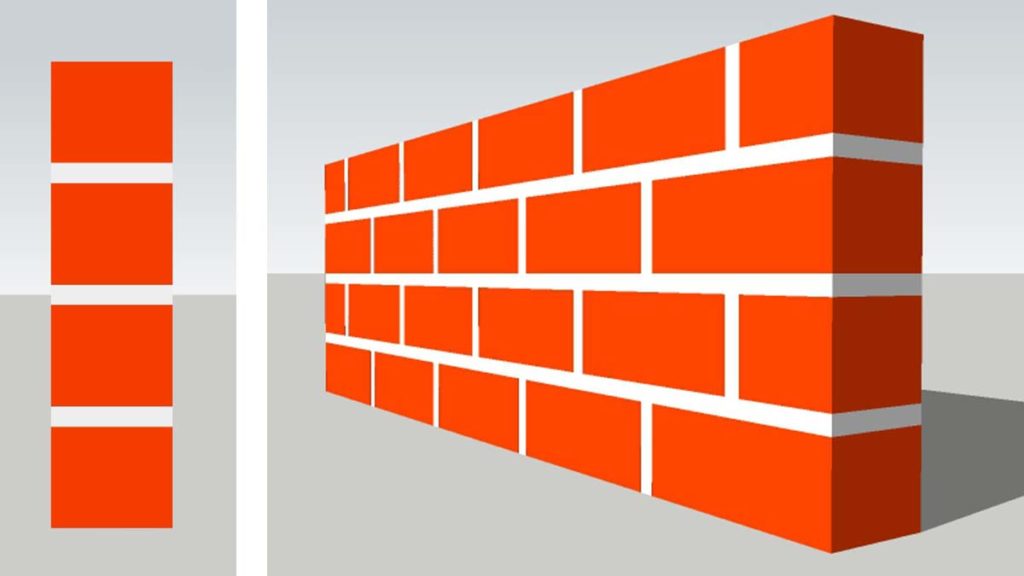

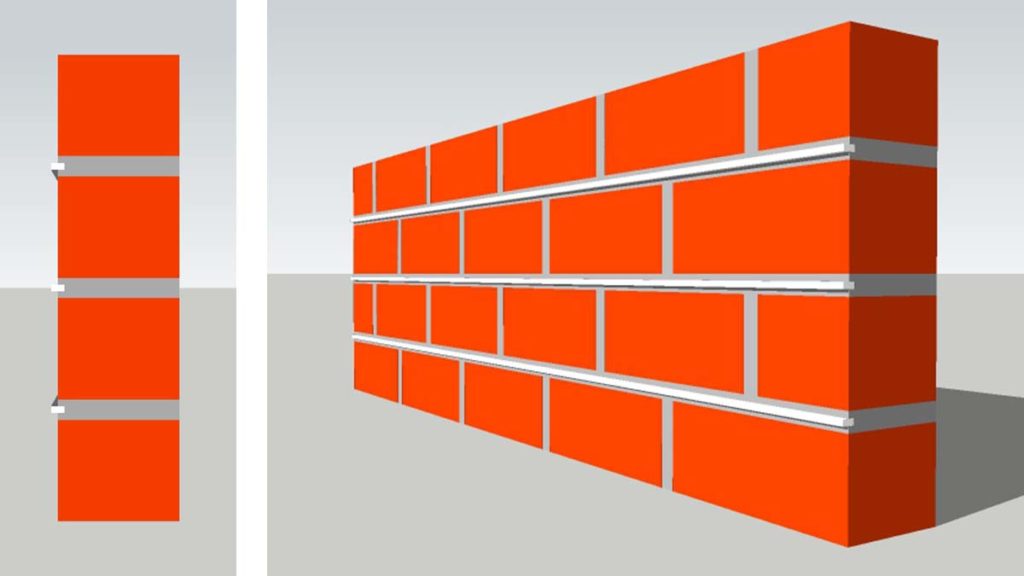

In this case, mortar is pressing back by 5mm or more from the edges. During the placing of mortar, the face of the pointing is kept vertical, by a suitable tool. This type gives a very good appearance. The figure on the left is a section view and isometric view of Recessed Pointing.

Weathered Pointing

Weather pointing is specifically designed to protect a masonry wall from the damaging effects of weather and moisture. The pointing of the joint is carried out by making a V-shaped projection from the face of the mortar line. This V-shaped projection helps to capture moisture and drip down on the ground thus preventing moisture from infiltrating the wall through the joints, which can lead to significant damage over time.

V- Pointing

Similar to Keyed pointing in preparation, it is also made by making a V-shaped groove in the flush pointing when the mortar is fresh and soft.

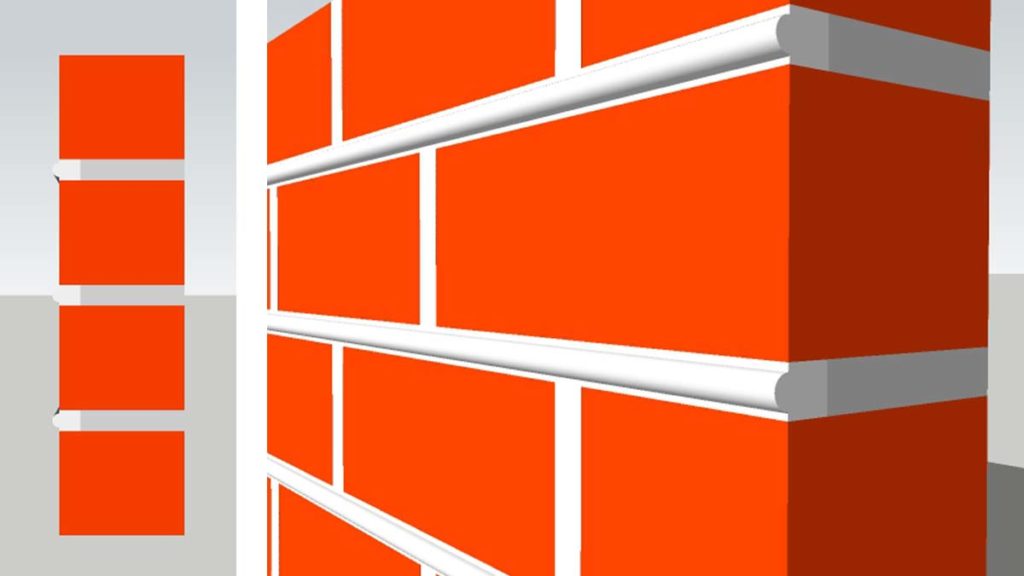

Beaded Pointing

Such a pointing is a type of pointing crafted by employing a special technique that makes use of a concave steel rod implanted into the refilled mortar joint to create grooves all along the joint. This process results in an improved appearance of the masonry joints, but the joints are susceptible to damage.

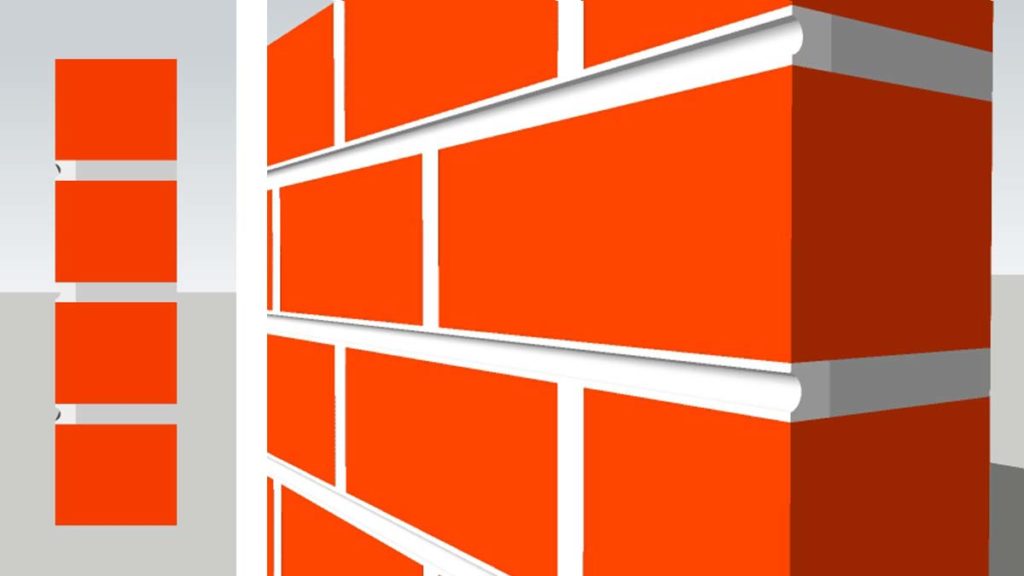

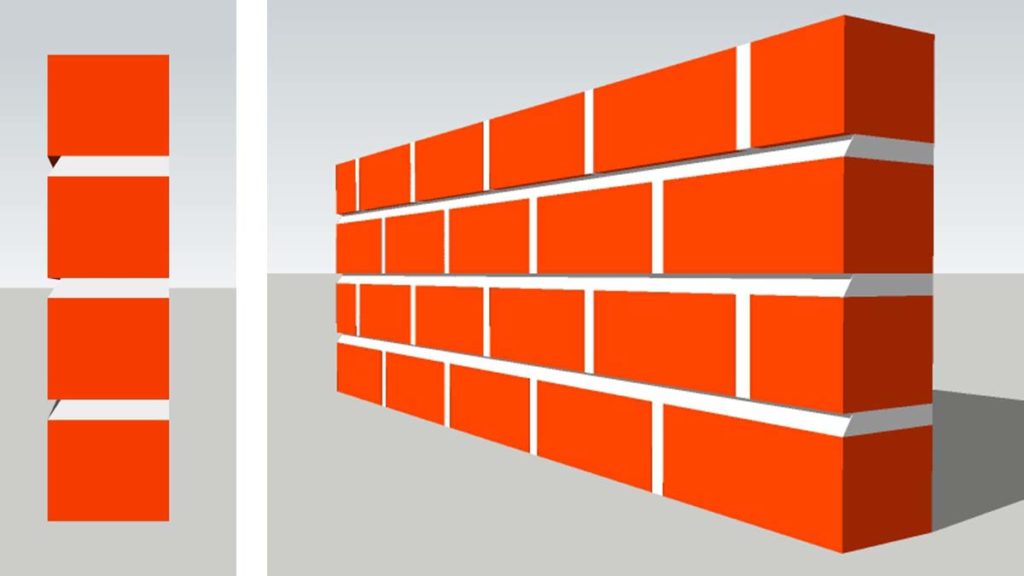

Struck Pointing

This is a modification of flush pointing. In this method, the joint is refilled with the mortar to the level of the brick edge. Then the mortar at the upper edge is pressed inside the face by 10mm making it included outside its bottom edge eventually creating a slope in the mortar. This pointing drains water easily. Such types of pointing looks exactly as shown in the figure below.

Tuck Pointing

This type of pointing is an improvement given to flush pointing. In this method of pointing, the mortar is first pressed in the rack joint and finished brick face as done in flush pointing. When the mortar is still fresh and green, a groove or narrow channel of 5mm width and 3mm depth is made in the centre with the help of the grooving tool. This groove is then filled in or tucked with white cement or putty keeping the portion projected beyond the face by 3mm. However, if the projection is made with the same material as mortar, it is called as Bastard pointing or half-tuck pointing.

Advantage of Pointing

- Comparatively pointing is cheaper than plaster for the matter of protecting the masonry walls.

- Protect the masonry joints from moister and water, which otherwise would cause damage to the masonry units.

- Elevate the appearance of the masonry walls with the application of designed pointing.

- Structurally strengthen the old masonry walls by reporting.

- Does not require skilled labour for the application of simple pointing works such as flush, Keyed pointing, etc.

Disadvantages of Pointing

- Some of the pointing works can be challenging as to construct Tuck and Beaded pointing.

- Projected and grooved pointing may be associated with dust accumulation.

Conclusion:

Plastering can be costly while pointing is a cheaper option for safeguarding masonry walls. Choosing to do pointing can enhance the appearance of masonry work, but ultimately, it’s up to the homeowner or designer. This article explores pointing in masonry, its advantages and drawbacks, and how it compares to plastering.

References:

- Bhavikatti, S. S. (2010). Basic civil engineering. IK International Publishing House Pvt. Ltd.

- Punmia. B.C (2006). A Textbook of Building Construction. Laxmi Publications (P) Ltd.

- Staff. Editorial (n.d.). 8 Types of Pointing in Brick Masonry Construction. Expert Civil. https://expertcivil.com/types-of-pointing/

- Anupoju. S. (Apr 22, 2016).Types of Pointing in Brick Masonry Construction. The Constructor. https://theconstructor.org/building/pointing-brickwork-construction/11290/

- Britannica, T. Editors of Encyclopaedia (2008, May 4). pointing. Encyclopedia Britannica. https://www.britannica.com/technology/pointing-brickwork

Also, read:

- What is Mortar? | Types of Mortars | Application

- What is Lime Mortar?

- Cement Mortar (CM): Its Property, Advantages & Usage

![]()