Good timber is everybody’s choice for the matter of building private properties, furniture, and application in construction projects. Timber, which is also referred to as wood, is a versatile and renewable natural material that has been used for various engineering applications such as construction and furniture making for many centuries worldwide. For timber to be suitable for engineering applications, it must possess specific essential properties. Here are some important properties of good timber that are necessary for engineering applications:

Properties of Good Timber

Durability:

Timbers are subjected to mechanical, biological and chemical deterioration. Mechanical deterioration of wood is due to physical wear as exposure to the exterior climate such as erosion of the material by wind and water, material fatigue caused by its repeated expansion and contraction, and the deterioration caused by freeze-thaw cycles (2009, M. Madan).

According to M. Madan PhD in 2009, “chemical deterioration of timber is caused by the impact of environmental chemicals such as acids and alkalies, as well as the chemical disintegration of the wood’s components caused by ultraviolet radiation from the sun.” When compared to mechanical and chemical deterioration, biological deterioration, known as biodeterioration, is the most severe issue. For timber to maintain its serviceability, it should possess the quality of resistance against all three types of deterioration.

Strength:

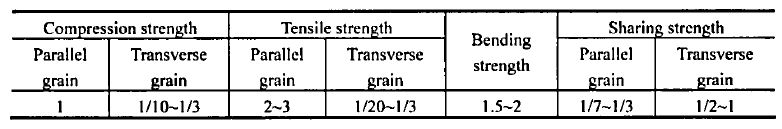

Timbers are used in multiple structures and non-structural components in the construction. According to Bhavikatti (2010), ” timber should have high strength in bending, shear and direct compression” (p. 26). Different types of timber have varying levels of strength. Also, “the parallel grain strength is quite different from the transverse grain strength” (Zhang, 2011, p. 244). Therefore, it is important to make good use of timber by looking at the table below.

Toughness:

“Timber should be capable of resisting shock loads” (Bhavikatti, 2010, p. 26). A good timber member should not fail under sudden impact load and vibration during its service in the structure. It has been suggested that timber with high toughness is better suited for engineering applications where resistance to shocks and impacts is required (The Constructor, 2021).

Hardness:

Hardness is an important property of timber which determines its ability to resist indentation or scratching. Hardness is measured by the Janka hardness test, which involves measuring the force required to embed a small steel ball halfway into the surface of the wood. Harder timbers require more force to be embedded and are more resistant to wear and tear.

Hardness can be influenced by several factors such as the species of the tree, the age and growth rate of the tree, the location and climate of the tree, and the type of grain pattern present in the wood. Generally, hardwoods such as oak, maple, and hickory are harder than softwoods such as pine and spruce, but there can be significant variations within each category of wood. Hardness is an important property to consider when selecting timber for applications such as flooring, furniture, and tool handles, where wear resistance is a key factor.

Density:

Generally, hardwoods have a higher density than softwoods, but there can be significant variations within each category of wood. The mean density of timber varies depending on the species of tree and the location and climate in which it was grown. For example, the mean density of softwoods such as pine and spruce ranges from about 400-700 kg/m³, while the mean density of hardwoods such as oak and maple ranges from about 600-1000 kg/m³.

High-density timber is generally stronger and more durable, making it suitable for applications such as structural support beams, while low-density timber is lighter and easier to work with, making it suitable for applications such as furniture, decorative panels, and paper production.

Permeability:

Permeability is an important property of timber that refers to its ability to allow liquids or gases to pass through its structure. Timber with high permeability can absorb moisture quickly and is more prone to swelling, warping, and decay. On the other hand, timber with low permeability is more resistant to moisture and is less likely to warp or decay.

In general, hardwoods tend to have a lower permeability than softwoods due to their more complex and denser cellular structure. However, some hardwoods, such as oak and ash, can have high permeability due to their open-cell structure. High-quality timber should have a moderate level of permeability that allows it to breathe and absorb moisture without becoming overly saturated. According to the “The Constructor” website, good timber should not absorb moisture more than 8 to 12% of water by its weight when placed in water (The Constructor).

For example, for use in outdoor decking or marine construction, a low permeability value is desired to ensure the wood is resistant to moisture and decay. In contrast, for use in indoor furniture, a slightly higher permeability value may be acceptable to allow the wood to breathe and maintain its natural moisture content.

Abrasion Resistance:

Abrasion resistance is another important factor to consider when selecting timber for flooring and decking applications. The ability of the timber to resist wear and tear due to foot traffic or other mechanical forces is critical to ensuring its durability and longevity.

Timber species with high abrasion resistance, such as oak or teak, are ideal for high-traffic areas or heavy-duty applications like decking on boats. Softer woods, like pine or cedar, may be more susceptible to abrasion and may not be suitable for high-traffic areas.

In addition to species selection, how the timber is cut and finished can also impact its abrasion resistance. For example, quarter-sawn timber tends to have greater resistance to wear and tear than flat-sawn timber due to its more consistent grain orientation.

Good timber should have high abrasion resistance to ensure its long-term performance in flooring and decking applications.

Also, read: Types Of Timber Flooring Depending Upon The Support | Specification | Method | Guide

Fire Resistance:

The fire resistance property of timber refers to the wood’s ability to resist ignition and the spread of fire. Timber is a combustible material and can contribute to the spread of fire if not properly treated or protected. With proper treatment (application of fire-retardant chemicals or fire-resistant coatings) and design, timber can have good fire-resistance properties.

Among all types of timber, it is noticeably observed that dense wood offers more resistance to fire. Therefore, good timber should have high fire resistance properties.

Also, read: 10 Best Fire-Resistant Building Materials.

Workability:

The term “workability of timber” refers to the ease with which the wood can be shaped or manipulated using various tools and techniques, such as cutting, planing, and carving. The workability of timber is influenced by several factors such as the species of wood, moisture content and its grain orientation. The good property wood can be easily worked with for a particular project or construction works. Usually, woodworkers or carpenters consider the workability of timber by seeing the above factors.

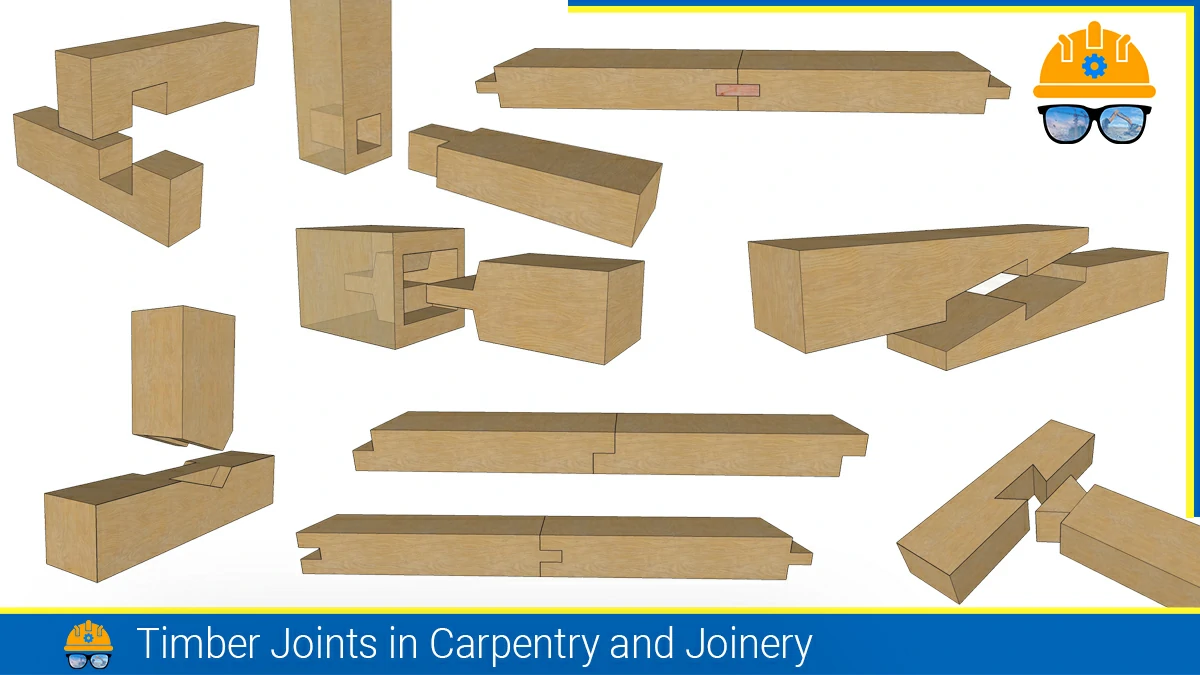

Also, read: Timber Joints In Carpentry And Joinery: A Better Way To Understand Timber Joint

Colour:

The colour of the timber plays an important role in determining its strength. According to the “The Constructor” website, “light colour designates low strength timber while dark colour indicates high strength timber. Hence, dark-coloured timber is preferable for engineering works.

The timber with the darker colour possesses a natural resistance to rot and insects as such cedar and redwood due to the presence of natural oils and tannins. While on the other hand, less resistant woods, such as poplar and basswood, are lighter in colour.

Timber with a distinctive grain pattern and rich colour is prized for furniture and decorative woodwork. For example, mahogany, teak and cherry have a rich, reddish-brown colour with distinct grain patterns. Other woods, such as pine and spruce, are lighter in colour and often used for construction purposes.

Defects:

Structural faults present within the timber that can weaken its strength, resilience, or durability are known as defects and should not be mistaken for surface blemishes. Dead knots, shakes, and cracks are examples of defects that good timber should be free from.

Modulus of Elasticity:

The modulus of elasticity is an important engineering property of high-quality timber, as it measures the material’s stiffness and its capacity to resist deformation when exposed to external forces. Timber with a higher modulus of elasticity is often preferred in construction, as it is stiffer and more resistant to deflection under load. Therefore, the modulus of elasticity is a key determinant of timber’s suitability for various applications in engineering, furniture making, and construction.

References:

- Mehta, M., Scarborough, W., & Armpriest, D. (2017). Building constructions: Principles, materials, and systems. Pearson Education, Inc.

- Bhavikatti, S. S. (2010). Basic civil engineering. IK International Publishing House Pvt. Ltd.

- Zhang, H. (Ed.). (2011). Building materials in civil engineering. Woodhead Publishing Limited.

- The Constructor. (2021). Characteristics of good timber for engineering applications. Retrieved April 4, 2023, from https://theconstructor.org/building/building-material/characteristics-good-timber/35288/#5_Toughness

![]()