Effective storage of cement is crucial to maintain its quality and performance. To ensure optimal results, it is essential to store cement in a dry environment, protected from moisture and humidity. Cement bags should be kept off the ground on pallets or other raised surfaces to prevent direct contact with the floor. Additionally, it is advisable to store cement in a well-ventilated area and away from direct sunlight.

Proper precautions should be taken to seal opened bags tightly to minimize exposure to air. By adhering to these guidelines, the longevity and effectiveness of stored cement can be preserved, ensuring reliable construction outcomes. This article is intended to highlight best practices for the duration of storage, location for storing, and precautions measures to be taken during storing cement.

Storage Of Cement

For storing cement at the construction site, it is of greatest importance to adhere to proper storage practices. By prioritizing the storage of cement, the construction site can ensure that the stored cement remains in optimal condition for its intended use, contributing to the success and durability of the project.

Precautions for Storage of Cement

There are necessarily certain precautions for the storage of cement that are essential to maintain its quality and usability. The precautions are mentioned below:

- Optimal Storage Conditions for Cement

- Arrangement of Cement Bags

- Duration Of Storage

- Retrieving of Cement

Optimal Storage Conditions for Cement

To ensure the optimal storage of cement, the storage area must be dry and well-ventilated, effectively preventing moisture absorption that could result in clumping and diminished effectiveness. Ideally, the designated building for cement storage should prioritize being dry, leakproof, and as moisture-proof as possible.

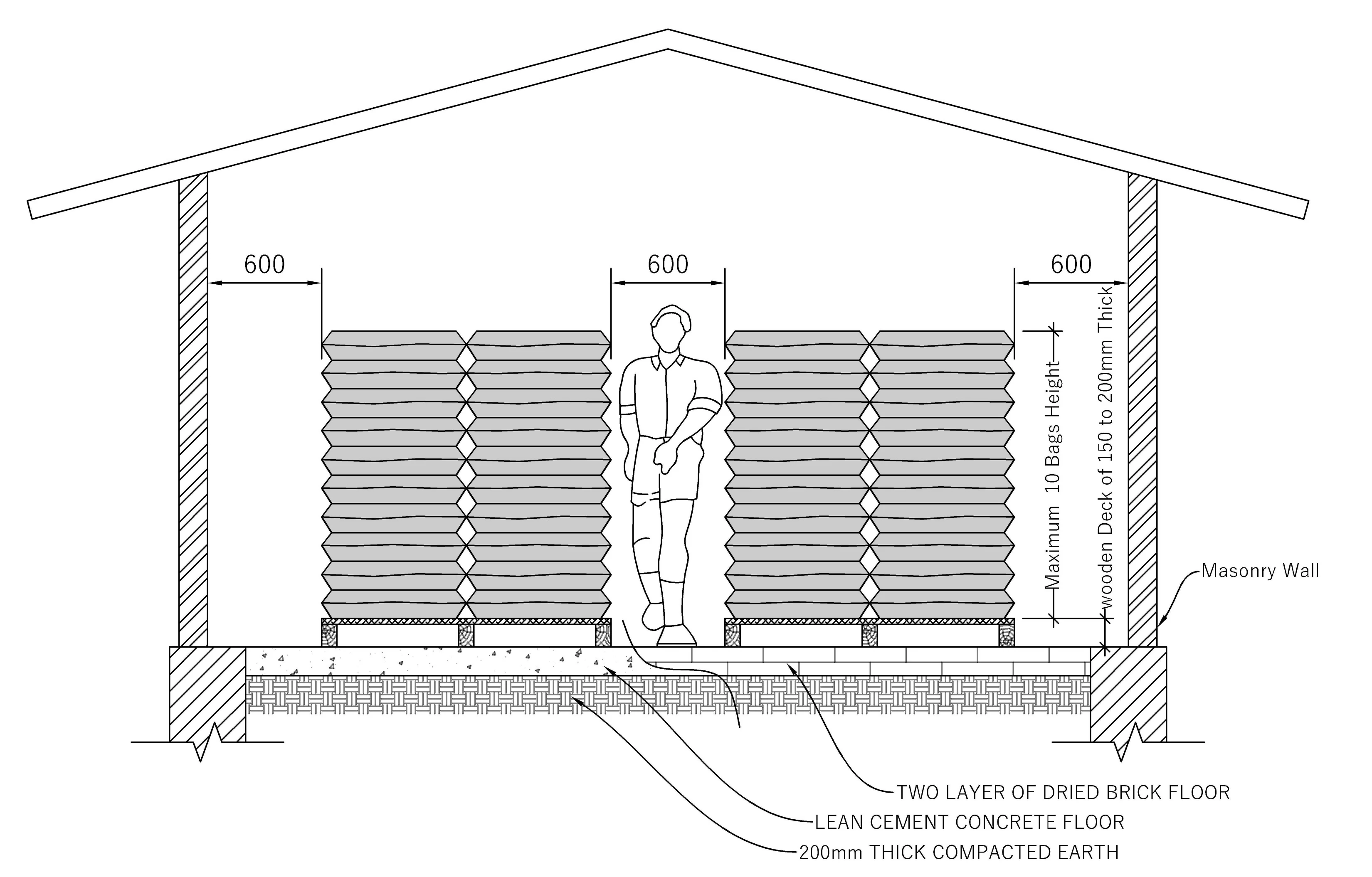

It is advisable to minimize the number of windows in the storage structure to reduce the potential for moisture ingress. Additionally, the flooring of the storage area can be constructed using lean cement concrete or two layers of dry bricks laid on a well-consolidated earth base, further enhancing the moisture-resistant characteristics of the storage facility. These measures collectively contribute to maintaining the quality and usability of stored cement over an extended period.

Palletization Techniques:

Palletization is a crucial technique for efficient and effective cement storage. To prevent contact with damp surfaces, it is advisable to store cement bags on pallets or raised surfaces, typically using wooden planks. This practice ensures that the bags are elevated, maintaining a clearance of approximately 150 mm to 200 mm above the floor.

Elevating the cement bags not only safeguards against moisture absorption but also facilitates proper air circulation around the bags, reducing the risk of clumping. Wooden pallets, when used, add an additional layer of protection by acting as a barrier between the cement bags and the potentially damp or cold floor. This palletization technique not only preserves the quality of the stored cement but also simplifies the process of handling, inventory management, and overall logistics in construction sites.

A separate pallet is required for stacking and storing different types of cement. Ensure that the cement bags are stacked close to each other to reduce the circulation of air between the cement bags stacked on the same pallet.

When it is required to store cement for a long period or during the monsoon; completely enclose the stack by a waterproofing membrane such as polyethylene.

Also, read: Ordinary Portland Cement: Properties, Composition, Manufacturing And Uses

Arrangement And Stacking Guidelines for Cement Bags

Stack the cement bags in such a manner as to facilitate their removal and use in the order in which they are received. Put a label showing the date of receipt of cement on each stack of cement bags to know the age of the cement.

The height of the stack of cement should not be more than 10 bags. The guideline of restricting the height of the cement stack to a maximum of 10 bags serves a critical purpose in preventing the occurrence of lumping under pressure. This precautionary measure ensures that the weight and pressure exerted on the lower bags do not lead to undesirable clumping, which could compromise the quality of the stored cement.

The width of the stack should not be more than four bags in length or 3 meters. The limitation on the width of the stack to no more than four bags in length or 3 meters is a strategic consideration. This restriction helps maintain the stability of the stack, preventing excessive width that might otherwise result in an unstable arrangement. It mitigates the risk of the stack collapsing or becoming unmanageable.

In situations where cement bags are stacked to a height exceeding 8 bags, a strategic arrangement becomes essential to enhance the stability of the stack. The recommendation is to arrange the cement bags alternately, both length-wise and cross-wise. This meticulous arrangement serves a dual purpose in reinforcing the structural integrity of the stack and reducing the potential hazards associated with tall stacks or mitigating the risk of toppling over.

Furthermore, the emphasis on stacking cement bags in a manner that facilitates easy removal and usage in the order of their receipt is a practical consideration for efficient logistics at the construction site. This organized approach ensures that the cement is utilized in a timely manner and in the sequence it was delivered, preventing issues related to the prolonged storage of cement.

Also, read: Portland Cement: Properties, Composition, Manufacturing Types And Uses

Duration Of Storage

The duration of storage of cement is an important factor for the strength of cement. The strength of cement is better achieved when used within the limited time of storage. It is best to be used before 3 months of storage before it loses its strength. With the prolonged duration of storage, there is a decline in the strength of the cement. It is advised to conduct the test for the cement stored for more than 3 months. The following table shows the decline of cement strength with respect to the increase in storage duration.

| Period of storage | Less than 3months | 3months | 6months | 1year |

|---|---|---|---|---|

| % Reduction in strength at 28 days | 0% | 20% | 30% | 40% |

From the above table, it is understandable that the cement loses its strength by 40% when stored for 1 year. However, the quality of cement can be regained by vibro grinding. This process can improve the finest of the cement.

Also, read: Test For Standard Consistency Of Cement

Retrieving of Cement

The practice of labelling each stack with the date of cement receipt adds an element of quality control. Knowing the age of the cement becomes crucial for construction projects where the freshness of the material can impact the overall strength and performance. This simple yet effective labelling system allows for the easy tracking of the cement’s age, enabling informed decision-making regarding its use in various stages of construction.

The retrieving of cement from the store happens when the time comes from the usage of cement. The cement bags placed first in the store shall be retrieved first and others with their time of storage. This will prevent the ageing of cement storage in the store.

Storage of Cement In Drums

If cement is received in drums, these drums shall be placed on the plane level of the ground and as possible near the concrete mixture. The seal of the drum shall be broken when arriving and placed at the site. Also, the lid of the drum shall be securely tied to prevent ingress of moisture, after taking out the required quantity of cement from the drum.

Also, read: What Is Water-Cement Ratio? | Calculation Of W/C | Value Of W/C

FAQs:

Q: How many days cement can be stored?

And: If stored properly and protected from coming in contact with moisture, cement can be stored for at least one year. However, it is recommended to be used before 3 months as it loses its strength over time.

Q: Can we use cement after 3 months?

Ans: Cement can be used after 3 months if it is properly stored and protected from coming in contact with moisture. However, it is always advised to carry out the test for the cement and check the quality of cement after 3 months of storage before use.

Q: How many cement bags can be stacked while storing?

Ans: The number of cement bags that can be stacked while storing depends on several factors, including the size and weight of the bags, the storage conditions, and safety considerations. However, there are some general guidelines to follow:

Height Limit: It is recommended not to stack cement bags more than 10 bags high to prevent the possibility of lumping under pressure. Exceeding this height could compromise the stability of the stack.

Weight Limit: The weight of the cement bags and the load-bearing capacity of the storage surface are critical factors. Stacking too many bags on a weak surface can lead to instability and collapse.

Storage Conditions: Consideration should be given to the environmental conditions of the storage area. For instance, if the area is prone to vibrations, extreme temperatures, or moisture, it might impact the stability of the stack.

Safety Regulations: Depending on the local safety regulations and guidelines, there may be restrictions on the maximum height or weight of stacked materials. Adhering to these regulations is essential to ensure a safe working environment.

References:

- Bureau of Indian Standards – e-Sale search result. (n.d.). https://standardsbis.bsbedge.com/BIS_SearchStandard.aspx?Standard_Number=IS%204082&id=10888

- (2009). CPWD Specifications (vol.1). Published By Director General Of Works, CPWD, Nirman Bhawan, New Delh

![]()