Timber, a versatile and renewable resource, has been a cornerstone of construction throughout human history. What sets carpentry and joinery apart is not just the assembly of wooden elements but the artistry involved in crafting joints that seamlessly connect beams, posts, and panels.

In the construction, the marriage of craftsmanship and functionality finds its true expression in timber joinery. Carpentry and joinery, the ancient arts of working with wood, have evolved over centuries, and their significance remains undiminished in contemporary construction practices. The intricate process of creating strong, durable, and aesthetically pleasing timber joints is a testament to the skill and precision required in these time-honoured trades.

Principles governing the construction of Timber joints

Timber joints play the most important role in timber construction since they provide structural stability, improve aesthetic appearance, and facilitate the construction. However, joints are the weakest parts of the timber structure. Hence the following principles, based on the recommendations by Prof. Rankine, should be followed in the construction of joints:

- The joint should be cut and placed in such a way that it weakens the connecting members to the minimum.

- Each abutting surface of the joint should be, as far as possible, normal to the line of pressure coming upon the joint.

- Wach abutting surface of a joint should be designed for the maximum compressive stress likely to come upon it.

- The surface of a joint should be formed and filled accurately so that there is an even distribution of pressure.

- The fastenings should be proportioned so that they possess equal strength in relation to the members with whom they connect.

- Fastening should be placed and designed in such a manner as to avoid failure of the joint by shear or crushing.

- The joint should be as simple as possible. Complicated joints are difficult to construct, take more time, are easily affected due to shrinkage of timber and get easily attacked by vermins due to the presence of many surfaces and angles.

Classification of Timber joints

Various types of joints used in woodwork may be classified under the following heads:

- Lengthening joints

- Widening joints or side joints

- Bearing joints

- Framing joints

- Angle or corner joints

- Oblique shouldered joints

Lengthening Joints

These types of timber joints are alternatively referred to as spliced or longitudinal joints and serve the purpose of extending the length of wooden elements like ties and struts. The specific method of elongation depends on the placement of the member within a frame structure, where these joints are frequently needed. The various types of lengthening joints include:

- Lapped joints

- Fished joints

- Scrafed or Spliced joints

- Tabled joints

1. Lapped Joints: This is the simplest type of joint and it is created by aligning the two ends of the members, allowing them to overlap for a short distance. These ends are then secured together using wrought iron straps and bolts. In instances where the member bears tensile stress, the joint typically involves bolts passing through both pieces.

2. Fished Joint: In this type of joint, the ends of two members are squared off and positioned in direct contact with each other. To connect them, wooden or iron fish plates are applied to opposing faces and fastened by bolts passing through them. The tips of the fish plates are gently bent and pressed into the members for added stability.

3. Scarfed Joint: In this joint, projections are made at the ends of one piece and corresponding depressions are formed in the other pieces. The two pieces are then secured together by means of bolts, straps, fish plates and keys. Such joints give a good appearance since the uniform depth of the members is obtained.

4. Tabled Joint: These joints are formed when the members are subjected to both tension as well as compression. It is similar to the spliced joint but is formed by cutting special shapes in both pieces and securing them with fish plates, bolts, keys etc.

Widening Joints

Such timber joints are also called side joints or boarding joints and are used for extending the width of boards or planks. The members are placed edge to edge. These are used for wooden doors, timber floors, etc. They are of the following types:

- Butt Joints: The butt joint as a widening joint is the most common type of joint used in timber flooring. It is also known as a square, plain or ordinary joint.

- Rabbet Joint: It is formed by overlapping the cut portions. The joint remains dustproof after the shrinkage of timber.

- Rebated and Filled Joint: It is formed by introducing a wooden fillet in the rebated portions, having a small depression. It is used for floors of factories etc.

- Plouged and Tongued Joint: It is formed by introducing a wooden fillet in the groove cut in the two pieces.

- Tounge and Grooved Joint: It is formed by making fillets in one piece and grooves cut in the two pieces.

- Rebated, Tongued and Grooved Joint: It is formed by forming a rebate in addition to the tongue and groove. The nail is placed in such a way that it cannot be seen.

- Splayed Joint: It is formed by splaying the ends. The joints are used only for ordinary purposes but are superior to the butt joint.

- Dowelled Joint: It is formed by making grooves in the centre portion of the end of each piece and inserting dowels of slate, gun-metal brass, bronze or copper. This is a very strong joint.

- Matched and Beaded Joint: This joint is similar to tongue and groove arrangement, and has special moulding on one side to give a good appearance.

- Matched and V-Joint: It is formed by providing a key dovetail shape to fit in the corresponding grooves in the connecting members.

Also, read: Types Of Timber Flooring Depending Upon The Support | Specification | Method | Guide

Bearing Joints

Bearing joints are provided when two members meet at right angles, to give sufficient strength to the functions. Bearing joints are of the following Types:

1. Halved Joint: These joints are formed by cutting through half the depth of each member meeting at right angles so that the top surface of both members is flush. This type of joint is of five types as shown in the figure below.

2. Notch Joint: It is formed by forming a notch in one or both of the members to be connected. This type of joint is of two types.

3. Cogged joint: This joint is formed by cutting a small notch in the beam or timber member and providing notches is known as cog. The upper portion, in which only a small notch has been formed, retains its strength.

4. Housed Joints: It is formed by fitting the entire thickness of the end of one member for a short distance into another piece. It is used in stairs in which the ends or risers and treads are housed in the strings.

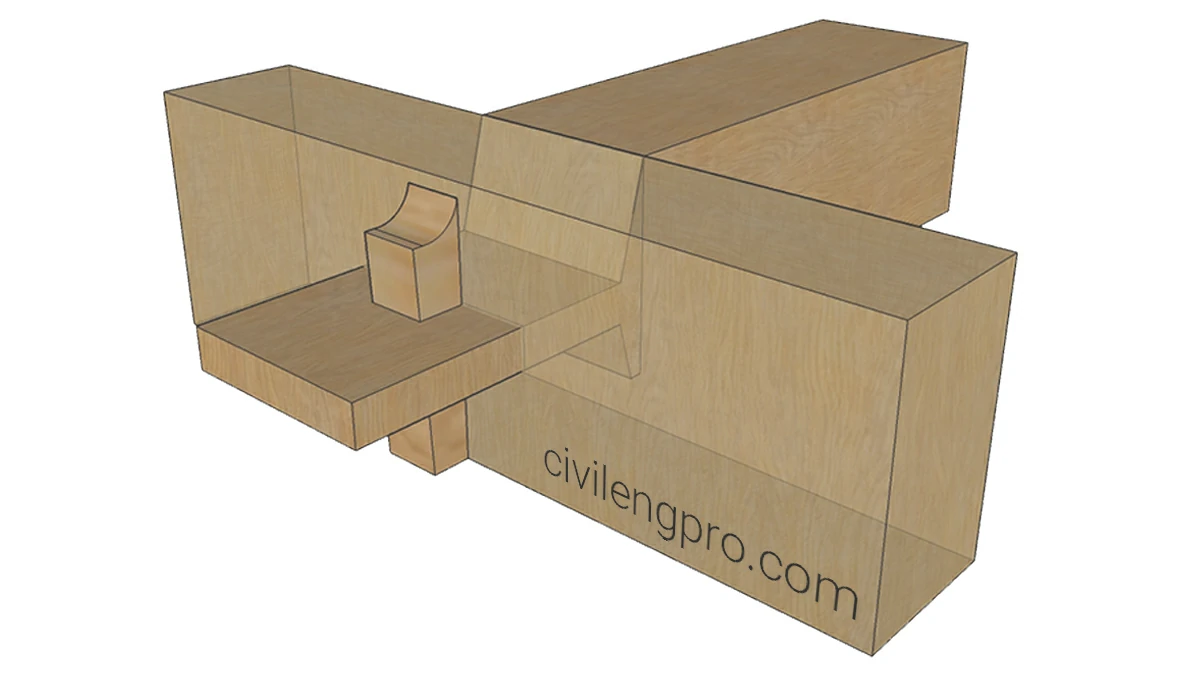

5. Chase-mortise Joint: This is used for jointing a subsidiary member to a primary (main) member already fixed earlier. A chase or recess of wedge shape is formed in the main member while a tenon of the corresponding shape is provided in the secondary member.

6. Dovetailed Joint: The joint is formed by cutting wedge-shaped or flaring-shaped pieces from each member and by hooking the projection of one member into the other. This joint is used for curbs of skylights and corners of boxes, cabinets, drawers etc.

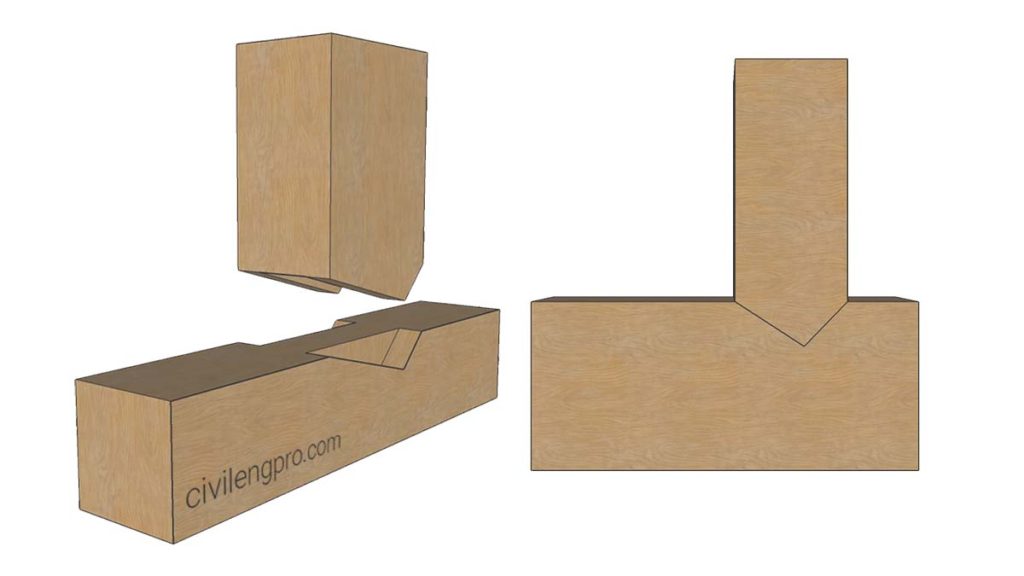

7. Mortise and Tenon Joint: The joint is formed by cutting projection, known as tongue or tenon, in one member which fits into a slot, called mortise, cut into the other member.

8. Joggle or Stump or Stub Tenon Joint: This is used for framing studs into the sill of a wooden partition wall. It is similar to a mortise-tenon joint except that the Tenon is short in length, and does not extend for the full depth of mortised member.

9. Bridle Joint: The joint is commonly used in wooden trusses at the junction of struts and ties. It is formed by cutting a type of mortise in the end of one piece to fit in the bridle or projection left upon another piece.

10. Fox-tail Wedging Joint: The joint is formed by cutting a slightly dovetailed mortise to a lesser depth than the member. The tenon is cut and two sockets are made in the tenon in which wedges are inserted. The entire assembly is then inserted into the mortise.

11. Tusk Tenin Joint: This joint is very strong and is commonly used in timber floor construction. The joint is formed of a tenon, tusk and horn. It is employed for joining members of equal depth and meeting each other at right angles. The tenon should be mortised in the centre of the members. A wedge is employed to strengthen the joint.

Also, read: Properties Of Good Timber In Civil Engineering

Framing Joints

Framing joints are used to construct the frames of doors, windows, ventilators, etc. These joints are similar to bearing joints except that they are not supported to carry stress as compared to bearing joints. The method of cutting the grooves and tongues in the members of the frame is suitably altered to obtain the desired form of the joint.

Angle or Corner Joints

Corner joints are used where two members are to be framed so as to form a corner or angular edge. Their joints are very often secured by railing. Glue is used for making these joints. The following are commonly used angle joints:

Butt Joint: The members are connected just by joining them edge to edge. The joint may sometimes be rebated and beaded to give a better appearance. The joint may also be tongued.

Groove and Tongue Joint: The joint is formed by fitting the projection )or tongue) of one member into the groove of the other.

Plain Mitred Joint: The joint is formed by cutting the edge of both members at an angle.

Mitred and Feathered Joint: In this an additional wooden member is inserted in the middle of the mitre joint.

Housed Joint: The joint is formed by fitting one member completely into the depression of the other.

Shouldered and Housed Joint: This joint is similar to the housed joint, but a part of one member fits into the corresponding depression of the other.

Dovetailed Joint: This is a special type of housed joint in which one member is housed into the other by a dovetail-shaped projection and cut.

Mitred and Rebated Joint: This joint is formed by using a rebate in addition to a mitre.

Mitred, Rebated and Feathered Joint: This joint is formed by inserting a feather in the above joint.

Tongued, Grooved and Mitred Joint: This joint is formed by making a tongue and groove in the lower edge of the mitre, to give the improved appearance.

Oblique Shouldered Joints

These joints are used where members to be joined meet at an acute or obtuse angle, such as in timber truss construction where the principal rafter, tie beam, structs, etc meet obliquely. The following are the common types of oblique joints:

Bird Mouth Joint: This joint is formed by cutting an angular notch (called a bird’s mouth) in the main member, to which the other member is partly inserted and fitted.

Oblique Tenon Joint: This is used for connecting a horizontal member to an inclined member, both the members being of bigger size. The tenon of the inclined member is oblique, which fits into the corresponding mortise hole of the horizontal member. The joint is further strengthened by bolts, keys, straps, etc.

Also, read: Types Of Doors Used In Building Construction | 11 Types

References:

- Punmia. B.C (2006). A Textbook of Building Construction. Laxmi Publications (P) Ltd.https://books.google.nr/books?id=_kAvTMzKGhAC&printsec=copyright#v=onepage&q&f=false

- Prasad, L. (2023, March 20). 16 different types of wood joints. ElectronicsHub. https://www.electronicshub.org/types-of-wood-joints/

![]()