Door Frame

A door frame is an assembly of horizontal and vertical members forming an enclosure, to which door shutters are fixed. A door frame serves as a fundamental component in the architecture of buildings, providing structural support and defining the boundary between spaces. They are typically composed of wood, metal, or a combination of materials, a door frame surrounds and supports the door, contributing to both functionality and aesthetics.

Functionally, a door frame plays a crucial role in maintaining the stability of the door. It provides a sturdy structure to which the door is attached, allowing it to swing open and shut seamlessly. The frame also contains hinges and a latch or lock mechanism, facilitating the door’s movement and securing the entryway when necessary.

The size of the frame is determined by allowing a clearance of 5 mm to both the sizes and the top of the opening. The cross-section area of the posts and the head is generally kept the same.

Component of Door Frame

The door frame consists of several components which hold the functionality and integrity of the door as a whole. The components are as mentioned below.

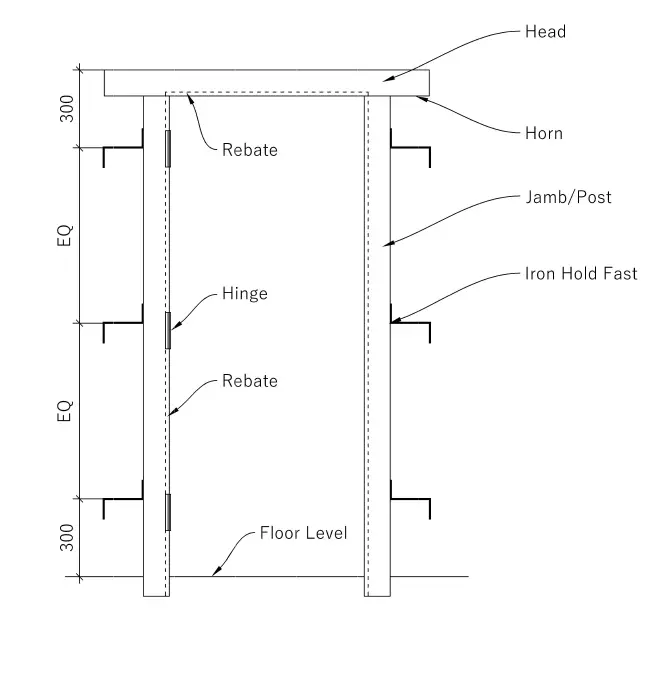

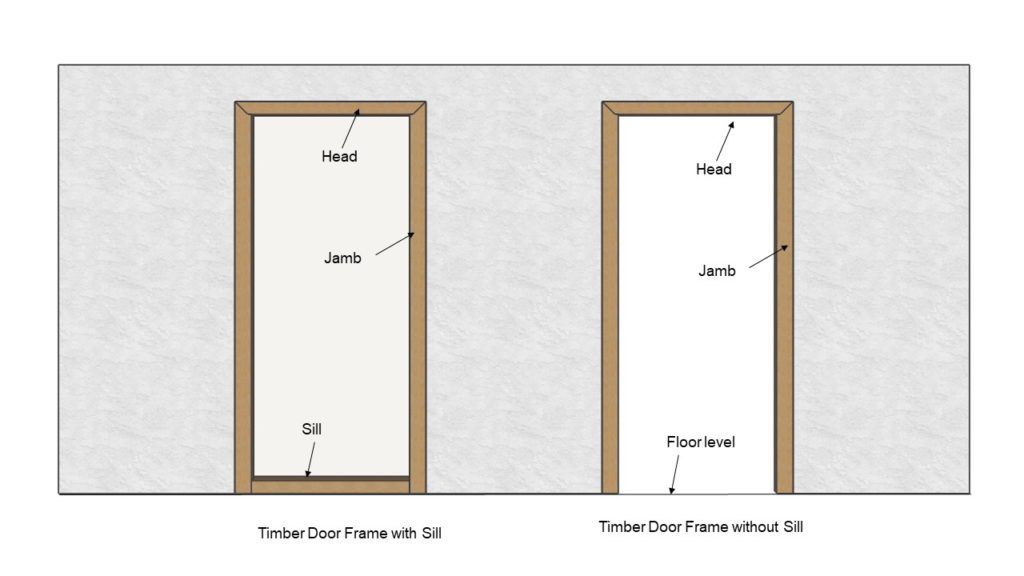

- Jamb: The two vertical components of the door frame, forming the sides are also known as posts. The door attaches to the hinges mounted on the jamb.

- Head: The horizontal part of the frame which is situated above the door connecting the jamb/post is called as Head, and has a horn. The head provides structural support to the door assembly.

- Sill: The horizontal piece at the bottom of the frame, forming the base and supporting the door. It is occasionally referred to as a threshold. A door frame without the sill is called an open door frame and with a sill is a closed door frame.

Door Frame Size for Timber

The finished dimension for a timber door frame really depends upon the shutter supported by the frame and the types of timber used to fabricate the frame. However, it varies from 60 to 75 mm for both Head and Jambs.

| S.No. | Shutter Thickness (mm) | Thickness of Head and Jambs (mm) | Width of Head and Jambs (mm) |

|---|---|---|---|

| 1. | for 35, 40 | 75 | 100 |

| 2. | for 25, 30 | 60 | 90 |

| S.No. | Shutter Thickness (mm) | Thickness of Head and Jambs (mm) | Width of Head and Jambs (mm) |

|---|---|---|---|

| 1. | for 35, 40 | 100 | 120 to 140 |

| 2. | for 25, 30 | 90 | 120 |

Also, read: Types Of Doors Used In Building Construction | 11 Types

Types of Door Frame

Depending upon the need for door types, a door frame may be assembled, fixed, and installed in the specified area. However, door frames come in a wide range depending upon their construction materials.

Based on the Design

- Open Door Frame

This is a type of door frame which does not have a bottom horizontal frame known as a sill or threshold. Such types of door frames are used when clear access is a high priority and it is achieved by keeping the clear span till the floor level. Open-door frames are usually opted for public buildings, shops or where wheelchair access is required. This frame may be constructed to suit either an inward opening or an outward opening of the door.

- Closed Door Frame

This frame style includes a sill or threshold positioned at the lower part of the frame, just above the floor level or resting on the floor. The sill can be customized to accommodate the shutter or door leaf. Similarly to the open door frame, this frame is adaptable for both inward and outward door openings.

- Fanlight Door Frame

In the aforementioned two designs, supplementary elements have been introduced to enhance both lighting and aesthetics. The incorporation of a transom above the door is specifically termed a glazed fanlight frame.

- Sidelight Door Frame

Like the previously mentioned frame design, an additional frame known as a mullion is introduced alongside the post which houses the glass panel, and it can be positioned on one side or both sides. This particular design is referred to as a sidelight frame which has the advantage of bringing in more sunlight when even the solid door is closed. It also adds the advantage of making the door more attractive and beautiful.

Based on the Preformed Opening

The frame is assembled and fixed into either a preformed opening or built into the shell of the building as the brickwork progresses.

- Inward Opening

A door frame configured for inward opening is designed to facilitate doors that swing into the interior of a building or room. In this setup, the hinges are positioned on the inner side of the door frame.

If the door shutter is demanded to be opened inward, the frame is built for fixing the shutter opening inward. This is usually preferred for residential buildings, public toilets, etc.

- Outward Opening

An outward-opening door frame is designed to accommodate doors that swing open towards the exterior of a building or room. In this configuration, the hinges are situated on the exterior side of the door frame.

This configuration is typically favoured for school buildings, hospitals, and other public structures where significant crowds congregate. Outward-opening doors facilitate the smooth flow of traffic, allowing for swift evacuation during emergencies or disasters. This design ensures an efficient and rapid exit of people from the premises.

- Inward and Outward Opening

In this type, a door leaf can be opened inward as well as outward. The hinges placed can move 180 degrees facilitating the shutter opening inward and outward. The type of hinges used are double-action or saloon door hinges. Such a type becomes applicable in double swing doors and saloon doors.

It also offers advantages similar to an outward-opening door frame. An additional benefit is that the door shutter can open in either direction without disrupting the flow of traffic during peak hours. This type of door configuration is commonly favoured in settings such as shopping malls, banks, offices, and similar environments.

Also, read: What Should Be The Size Of The Window?

Based on the Materials used

Door frames are made of the following materials

- Timber

- Steel section

- Aluminium section

- Concrete and

- Stone

Out of these, timber frames are more commonly used. However, in factories, workshops, etc., steel frames are widely used. Aluminium frames are costlier and used for residential buildings where more funds are available. With the increasing cost of timber and the increasing menace of termites, concrete frames are now becoming popular in urban areas. Concrete frames are found to cost less than half the cost of teakwood frames; it is also cheaper than iron frames. Stone frames are used mostly in villages, especially where good quality stone is available, in the required size. The jambs or posts, head and sill of the stone door frame are finely dressed and are jointed by forming proper holes and corresponding projections.

Among these options, timber frames see more widespread usage. However, steel frames are extensively employed in settings like factories and workshops. Aluminium frames, though pricier, find application in residential constructions with ample financial resources. The escalating expense of timber and the growing threat of termite infestations have led to the rising popularity of concrete frames in urban areas.

Concrete frames have been discovered to be significantly more cost-effective, costing less than half of what teakwood frames demand, and are also more economical than iron frames. Stone frames are predominantly utilized in rural areas, particularly where high-quality stone in the required dimensions is readily available. The jambs or posts, head, and sill of the stone door frame are meticulously dressed and connected by creating appropriate holes and corresponding projections.

Also, read: Properties Of Good Timber In Civil Engineering

Timber Door frame

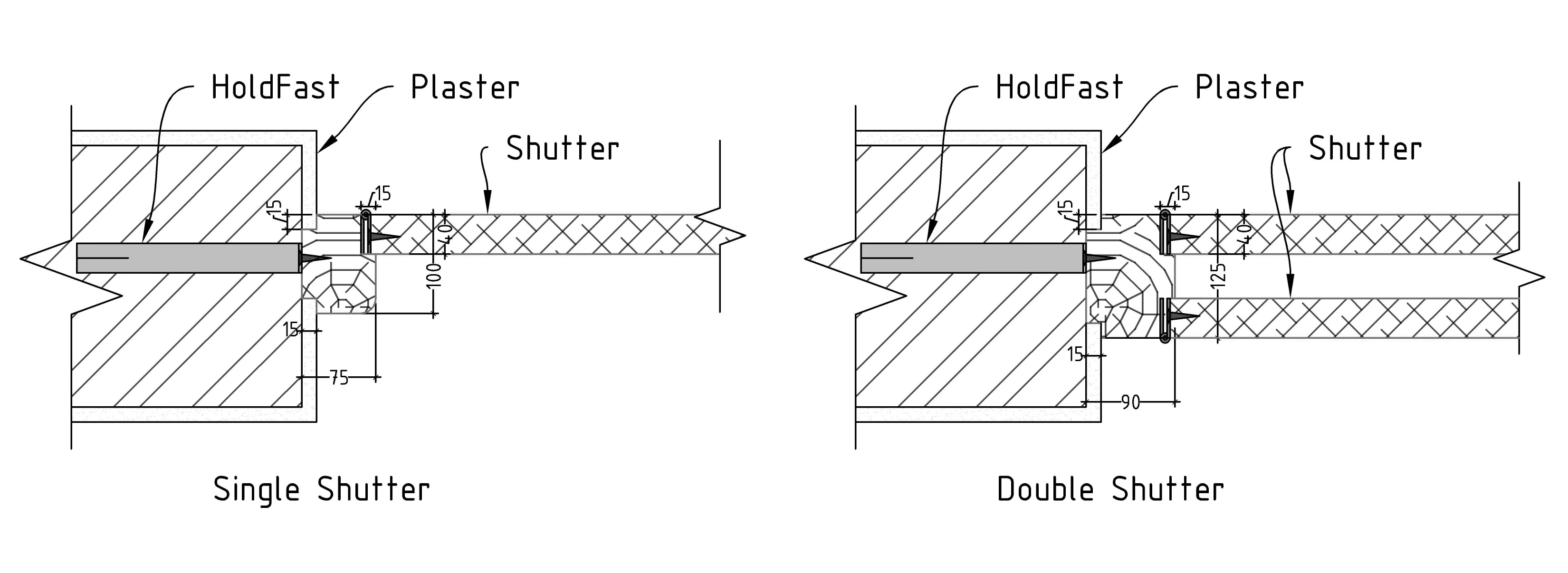

Generally, timber door frames are fabricated from both hardwood and softwood. They are preferred because they look much better than other materials, and they can be polished if desired. The thickness of timber varies from 60 to 75 mm, depending upon the size of the door opening and the type of timber used. The same thickness is used for jambs as well as heads. The width of the door frame is taken as 100 mm if the door has a shutter to open one side only and 125 to 140 mm if the shutters are provided to both sides of the frame (such as a panelled shutter to one side and fly proof wire-mesh shutter to the other side).

The frame is grooved on both the inner edges to receive plaster the depth of rebating being equal to 10 mm. In ordinary works, this grooving is avoided. Similarly, the frame is rebated at its outer edge to receive the shutter. The width of rebating varies from 12.5 to 15 mm while the depth is kept to the thickness T of the shutter. In case the door has a shutter on both sides, rebating is also done on both the edge of each jamb and the head.

The joint between the vertical post and the head of the frame may be of the following types:

- Closed mortised and tenoned joint

- Pin and tenoned joint

- Dovetailed joint, This joint is advocated in the Indian standard for use in the post, with a corresponding recess in the head of the frame.

Also, read: Different Types of Flush Doors | 4-Types

Steel Door frame

Steel door frames are made of any of the following sections:

- Single angle iron

- Double angle iron

- T-section

- Channel section

Steel holds fast or lugs are welded to the frame. Steel frames are generally fixed in prepared door openings. Chases are cut in brick masonry for accommodating hold fast or lugs which are then grouted with cement mortar. The vertical jambs and the head of the frame are welded together. The hinges of the shutter are also welded to the frame. In the case of stone masonry or R.C.C. where it is difficult to cut chases, wooden plugs are embedded at appropriate places in the jamb during the construction of the wall. The steel frame is fixed with plugs with the help of galvanised iron wood screws of big size.

Steel door frames are manufactured from the following materials:

- Mild Steel Sheet (cold rolled)

- Galvanized Steel Sheet

- Stainless Steel (Grade 430 or 304)

References:

- Punmia, B.C (2006). A textbook of Building Construction. Laxmi Publications (P) Ltd. New Delhi-110002

- Bureau of Indian Standards. (2003). IS 4021.Timber Door, Window and Ventilator Frames — Specification (IS 4021: 2003). Bureau of Indian Standards. New Delhi 11002

- Bureau of Indian Standards. (2003). IS 4351.Stee Door Frames — Specification (IS 4351: 2003) (2nd Rev.). Bureau of Indian Standards. New Delhi 11002

- Doors, Door Frames and Linings. Section 10. Steve Wilson site. Practical Resources. https://stevewilsonsite.files.wordpress.com/2014/09/sec10_doors.pdf

![]()