It is important to understand the types of glass for structural applications that improve the appearance of buildings and reduce construction costs. Glass has become an important technical material in building construction, including windowpanes, wall and ceiling glazing, flooring, roof lighting, and decorative purposes. Glass is a supercooled liquid, not a true solid. It is amorphous and transparent or translucent. It’s not a single connection. The basic raw material for producing high-quality glass is silicic acid, which naturally occurs as SiO2 (quartz). It is made by fusing a mixture of several basic oxides of silicon dioxide, silicon, boron, or phosphorus with soda ash, potash, lime, or magnesia, along with a waste glass called a cullet.

Glass

Glass is usually a transparent or translucent material that has no crystalline structure, yet behaves like a solid. Common glass is generally made of a silicate (such as silicon oxide, or quartz) combined with other substances and melting the minerals at temperatures around 1700 degrees Celsius. Other materials that can be added to produce different colours or properties include minerals like cobalt or sulphur, etc.

Silica is the main constituent of glass. But it is to be added with sodium potassium carbonate to bring down the melting point. To make it durable lime or lead oxide is also added. Manganese oxide is added to nullify the adverse effects of unwanted iron present in the impure silica. The raw materials are ground and sieved. They are mixed in specific proportions and melted in the furnace. The glass items are manufactured by blowing, flat drawing, rolling and pressing.

Important Properties of Glass

The property of glass is that it can absorb, refract or transmit light. It can be made transparent or translucent.

- It absorbs, refracts or transmits light. It can be made transparent or translucent.

- It can take an excellent polish.

- It is an excellent electrical insulator.

- It is strong and brittle.

- It can be blown, drawn or pressed.

- It is not affected by the atmosphere.

- It has excellent resistance to chemicals.

- It is available in various beautiful colours.

- With the advancement in technology, it is possible to make glass lighter than cork or stronger than steel.

- Glass panes can be cleaned easily.

Types of Glass

The glass may be broadly classified as:

- Soda-lime glass

- Potash lime glass

- Potash lead glass

- Borosilicate glass

- Common glass and

- Special glasses

Soda Lime Glass:

Soda lime glass is a common and cheapest of all glass types. It is prepared by mixing sodium silicate and calcium silicate at a very low temperature. It is also referred to as soft glass. In the fusion condition, it can be blown or welded easily. It is colourless. The major disadvantage of using these types of glass is that it is brittle & breaks easily. It cracks when subjected to sudden changes in temperature.

Soda glass is used for the manufacture of window glass, mirrors, common glassware and for laboratory tubes and apparatus. It is easily attacked by chemicals.

Potash Lime Glass:

These types of glass are obtained by fusing potassium carbonate (potassium silicate) & limestone (calcium silicate). It is also known as hard glass. It fuses at high temperatures. It is used in the manufacture of glass articles which have to withstand high temperatures. It is more resistant to the action of acids.

Potash Lead Glass:

It is mainly a mixture of potassium silicate and lead silicate. It possesses bright lustre and great refractive power. It is used in the manufacture of artificial gems, electric bulbs, lenses, prisms etc.

Borosilicate Glass

Borosilicate glass is also known as Pyrex glass. Such types of glass are obtained from the fusion of silica, borax, lime and feldspar. Borosilicate glass contains 70-80% silicon dioxide, 7-13% boron oxide, and small amounts of potassium oxide and aluminium oxide. With the addition of boron, borosilicate glass exhibits excellent resistance to thermal and electrical shocks. They can withstand a temperature difference of 165 ° C without breaking. Unlike soda glass, borosilicate glass has a low coefficient of thermal expansion and can withstand thermal stress. Borosilicate glass is more durable and scratch-resistant than soda lime glass. It also has excellent chemical resistance.

Borosilicate glass has a wide range of applications from making laboratory equipment to cookware, scientific lenses for microscopes, and telescopes. Some of the application of borosilicate glass is shown in Figure 4.

Common Glass:

In the field of engineering, common glass is a mixture of sodium silicate, calcium silicate and iron silicate. It is brown, green or yellow in colour. It is mainly used in the manufacture of medicine bottles.

| Sl.No. | Types of Glass | Raw Materials |

|---|---|---|

| 1. | Soda-Lime Glass | Chalk, Soda ash, and Clean Sand |

| 2. | Potash Lime Glass | Chalk, Potassium carbonate (K2 CO3), and Clean Sand |

| 3. | Potash-Lead Glass | Litharge or Lead Sesquioxide (Pb3O4), and Pure Sand |

| 4. | Common Glass | Chalk, Salt cake (Na2SO4), Coke, and Ordinary Sand |

Special Glasses:

The properties of glasses can be suitably altered by changing basic ingredients and adding a few more ingredients. It has now emerged as a versatile material to meet many special requirements in engineering. The following is the list of some of the special glasses:

- Fiberglass

- Foam glass

- Bulletproof glass

- Structural glass

- Glass black

- Wired glass

- Perforated glass.

Fiberglass

Fibreglass consists of very thin fibres of glass possessing high tensile strength. The thinner the fibre, the higher the strength. It is soft to the touch and does not absorb water. It is also fireproof, vermin-proof, and resistant to acid. Glass fibres have become an important building material for plastic resins and even concrete.

Glass reinforcement plastic is commonly known as fibreglass. Such types of glass are used in manufacturing shockproof helmets, car bodies, boats, thermal insulators, etc.

Also, read: Glassfiber Reinforced Concrete (GFRC): Versatile Building Material

Glass Blocks

These are manufactured from pressed glass by fusing two or more sheets in such a way that a partial vacuum is created inside the blocks. Subsequently, these blocks are annealed to induce structural properties. The edges are coated with a grit-bearing plastic material so as to ensure effective bonding with mortar. These blocks are used in masonry construction to permit the transmission of light without being transparent.

The glass blocks are usually available in sizes of 15 cm X 15 cm, 20 cm X 20 cm, and 30 cm X 30 cm, having a thickness of about 10 cm. These blocks are not made to carry superimposed loads but possess the strength to bear their own weight up to a maximum height of 6 m. They are also capable of resisting the effect of lateral wind pressure. These blocks provide good insulation against cold, heat, and noise.

Structure Glass

These glasses are in the form of glasscrete or ferrogless which are set in cement concrete and reinforced with steel frames. These bricks can be used as light structure members. They are extensively used for pavement lights, partition walls, stairs, lantern lights, etc.

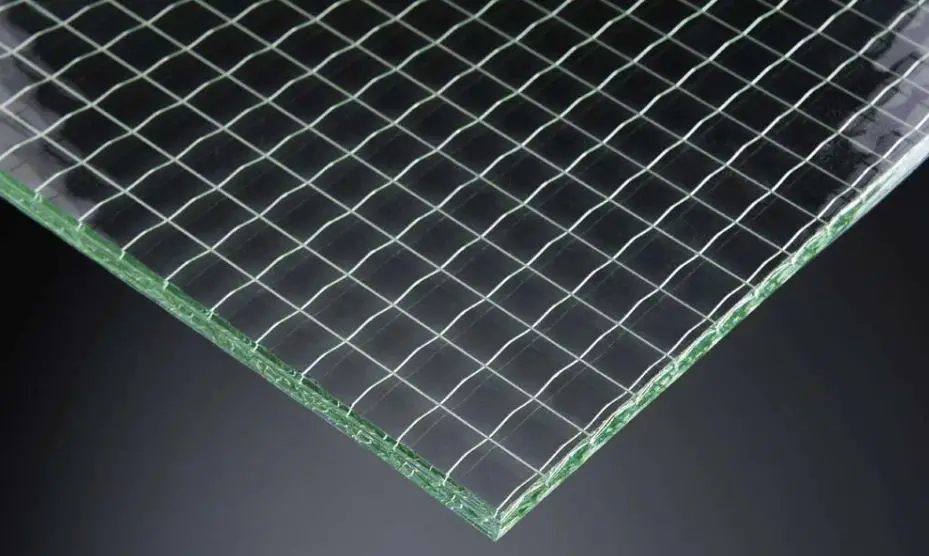

Wired glass

These are ordinary plate glasses of 5 mm to 6 mm thickness in which wire netting is embedded. The mesh may be hexagonal or square. If the glass breaks, the glass pieces are held in position. Steel wires being a good conductor of heat, these glasses are more resistant to heat.

These are used for roofs, skylights, fire-resisting doors, and windows, etc.

Also, read: Types of Doors used in Building Construction: 11 Types

Bulletproof Glass

These varieties of laminated glass are made by pressing together several layers of glass and vinyl-resin plastic in an alternate manner. The outer layers of plate glass are thinner than the inner layers. During manufacture, special care is taken for the heating and cooling of layers. The thickness of such glass varied from 20 mm to 75 mm or more. These are useful in vehicles and other automobiles for security considerations.

Summary

It is important to understand the types of glass for structural applications that improve the appearance of buildings and reduce construction costs. Glass has become an important technical material in building construction, including windowpanes, wall and ceiling glazing, flooring, roof lighting, and decorative purposes.

References: –

- S.S. Bhavikatti (2010), Basic Civil Engineering, New Age International (P) Limited,

- G. C. Sahu & Joygopal Jena (2015), Building Materials and Construction, McGrew Hill Education (India) Private Limited

- Types of Glass. In Believers in Glass. https://www.believersinglass.com/TypeOfGlass.php

- Glass. (2022, September 16). In Wikipedia. https://en.wikipedia.org/wiki/Glass

![]()