When the structure member of a building increases beyond 1.5 m, temporary structures are needed to support the platform over which the workman can sit and carry on the construction. This temporary structure constructed very close to the wall is called Scaffolding.

What is Scaffolding?

A temporary structure erected adjacent to the main structure during the construction or renovation activities of the building to provide a safe working platform at a convenient height is called scaffolding. They are provided when the working height or level is 1.5m or more above the ground level. It is usually constructed from timber or steel.

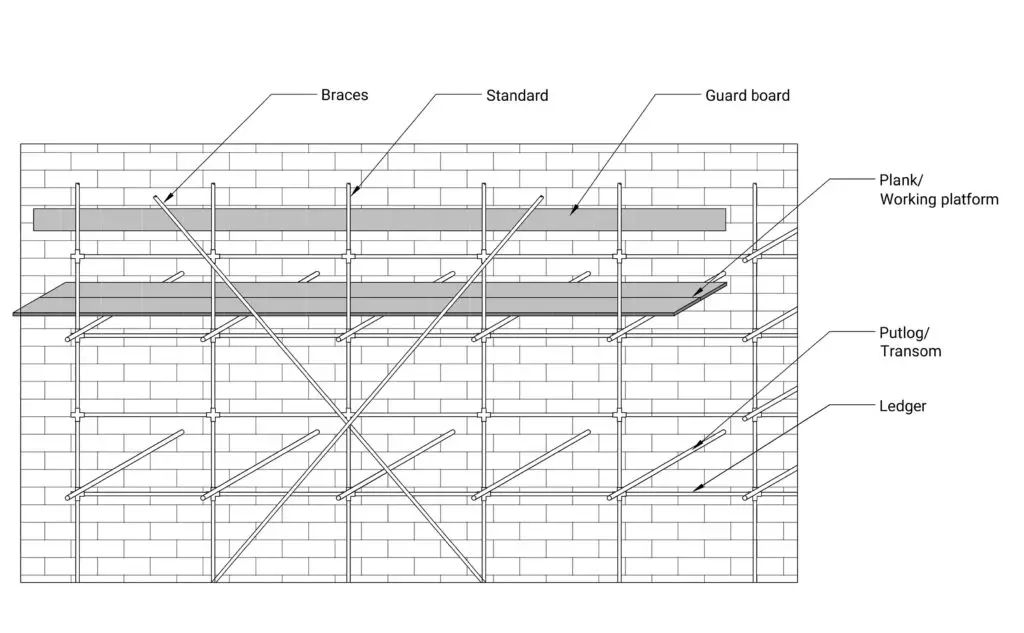

The Part of Scaffolding

The following components are some of the common parts of the scaffolding.

- Standards: These are the vertical members of the framework, supported on the ground or drums, or embedded into the ground.

- Ledgers: These are horizontal members, running parallel to the wall.

- Braces: These are diagonal members fixed on standards.

- Putlogs: These are transverse members, placed at right angles to the wall with one end supported on ledgers and the right end on the well.

- Transoms: These are those putlogs in which both ends are supported on ledgers.

- Bridle: This is a member used to bridge a well opening; supports one end of the putlog at the opening.

- Boarding: These are horizontal platforms to support workmen and material; these are supported on the putlogs.

- Guard rail: This is a rail, provided like a ledger, at the working level.

- Toe board: These are boards, placed parallel to ledgers, and supported on putlogs, to give protection at the level of the working platform.

Types of Scaffolding

The following are the types of scaffolding used in the construction:

- Single or brick-layer scaffolding

- Double or mason scaffolding

- Cantilever or needle scaffolding

- Suspended scaffolding

- Trestle scaffolding

- Steel scaffolding

- Patented scaffolding

1. Single Scaffolding

Single scaffolding is generally used for brick masonry works, It consists of a single framework of standards, ledgers, putlogs etc., which is constructed parallel to the wall at a distance of about 1.2 m. The distance between each standard is about 2 to 2.5 m. Ledgers connect the standards at vertical intervals of 1.2 to 1.5 m. Putlogs are taken out from the hole left in the wall to one end of the ledgers. Putlogs are placed at an interval of 1.2 to 1.5 m and are also known as putlog scaffolding.

2. Double Scaffolding

Double Scaffolding is generally used for stone masonry so, it is also called mason’s scaffolding. In stone walls, it is hard to make holes in the wall to support putlogs. So, two rows of scaffolding are constructed to make it strong. The first row is 20 – 30 cm away from the wall and the other one is 1m away from the first row. Then putlogs are placed which are supported by both frames. To make it more strong rakers and cross braces are provided. This is also called independent scaffolding.

3. Cantilever Scaffolding

The scaffolding may be single-type or double-type. In a single type, standards are supported on a series of needles and these needles are taken out through holes in the wall. In a double type, needles are strutted inside the floors through the openings.

This type of scaffolding is used under the following circumstances:

- The ground is weak to support standards

- Construction of the upper part of the wall is to be carried out

- It is required to keep the ground, near the wall, free from traffic etc.

4. Suspended Scaffolding

This type is used for repairing works such as pointing, painting, etc. This is known to be a lightweight scaffolding. The working platform is suspended from roofs by means of wire ropes or chains. The platform can be raised or lowered at any desired level.

5. Trestle Scaffolding

It is used for painting and repairing works inside the rooms. It can be operated to a maximum height of 5 m. The working platform is supported on the top of movable contrivances such as tripods, ladders, etc. which are mounted on wheels.

6. Steel Scaffolding

It is similar to timber scaffolding except that wooden members are replaced by steel tubes and rope lashings are replaced by steel couplets or fittings. It is very easy to erect or dismantle. The advantages of steel to timber scaffolds are that it has greater strength, durability and higher fire resistance. It is comparatively uneconomical to timber or bamboo. However, due to its greater advantages, it is extensively used to this day and can be used for both brick walls and stone walls.

7. Patented Scaffolding

It is made of steel which is equipped with special couplings and frame systems. The working platform is supported on brackets and easily adjusted at any suitable height. The members are connected together using an integral locking device instead of conventional clips and couplers used with traditional tubular scaffolding.

They have the benefit of straightforward assembly and disassembly even by semi-skilled labour.

References:

Also, read:

- Shuttering/Formwork for Structure Members for Building Construction

- Removal of Formwork | Stripping of Formwork

- What is Formwork?: Design Consideration of Formwork

![]()