Concrete is good in compression and has multiple applications in construction industries. Thus, concrete needs reinforcement to improve its weak tensile properties. In this article, we will see about “types of steel reinforcement bars”.

What are Reinforcement Bars?

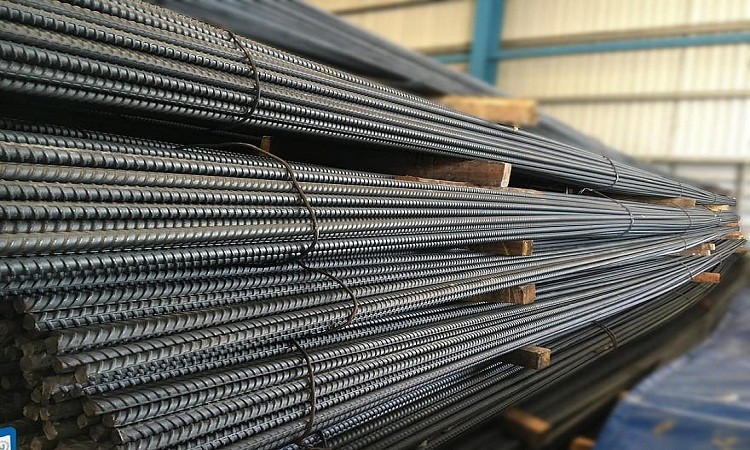

Reinforcement bars are steel bars that are provided in combination with plain cement concrete to make it reinforced concrete. Hence these structures form steel-reinforced cement concrete structures (R.C.C). Steel reinforcement is commonly called ‘rebars’.

Different Types of Steel Reinforcement Bars

The steel reinforcement bars used for the construction of concrete structures are mainly of 4 types. They are namely: –

- Mild Steel Plain Bars

- Cold-twisted bars

- Hot Rolled Deformed Steel Bars

- Prestressing Steel Bars

Mild Steel Plain Bars

Mild Steel and Medium Tensile Bars Conforming to IS: 432 (Part I) 1982 shall be used as reinforcement bars. Mild steel is of three types depending upon the grade.

Mild Steel (grade I) Bars

Mild steel bars are plain round and hot-rolled which are most commonly used for reinforcing concrete. These bars have plain surfaces and have a sufficient bond with concrete. These bars need hooks and bend at their ends for anchorages. These bars are bent easily and are weldable.

These bars are bent easily and are weldable. These bars are manufactured in nominal sizes of 5, 6, 8, 10, 12, 16, and 20 mm (with 255 N/mm2 as yield stress and 412 N/mm2 as ultimate tensile stress). These bars are also produced in 22, 25, 28, 32, 36, 40, and 45 mm nominal size (with 236 N/mm2 yield stress and 412 N/mm2 as ultimate tensile stress).

Mild Steel (grade II) Bars

Bars are manufactured in the above-mentioned nominal sizes (with 231 N/mm2 as yield stress and 373 N/mm2 as ultimate tensile stress) and from 22 mm to 50 mm nominal sizes (with 211 N/mm2 as yield stress and 373 N/mm2 as ultimate tensile stress).

Medium Tensile Steel Bars

Bars are manufactured in above nominal sizes up to 200 mm (with 353 N/mm2 as yield stress and 538 N/mm2 as ultimate tensile steel stress) and from 22 mm to 40 mm nominal sizes (with 348 N/mm2 as yield stress and 538 N/mm2 as ultimate

tensile stress) and 45 mm and 50 mm nominal sizes (with 323 N/mm2 as yield stress and 538 N/mm2 as ultimate tensile stress).

Hot Rolled Deformed Bars

These bars are also most commonly used for reinforcing concrete. The yield stress for this quality of steel is 415 N/mm2 and the ultimate tensile stress is 15% higher than the measured yield stress. Hot rolled deformed steel bars shall confirm to IS: 1139–1966.

Cold-Twisted Deformed Bars

Cold twisted deformed bars shall Conform to IS: 1786–1979 and are usually mild steel bars. The yield point of this quality of steel is eliminated by cold working. Generally, twisting under controlled conditions results in higher yield stress and consequently higher permissible (working) stress. These bars have lugs, ribs or deformations on the surface so that the bond strength with concrete is very high (at least 40% more than that of the plain bar of the same size).

Because of high yield stress (415 N/mm2) and deformations, this variety of steel is commonly referred to as high-yield strength deformed bars (HYSD bars). Cold-twisted deformed bars are manufactured in 6, 8, 10, 12, 16, 18, 20, 22, 25, 28, 32, 36, 40, 45 and 50 mm nominal sizes.

Cold-twisted bars are also produced with a high yield stress of 500 N/mm2. These two varieties of steel are referred to as Fe

415 and Fe 500, respectively. Fe 415 variety of this steel is very commonly used. Due to high bonding with concrete, these types of bars do not need hooks and bends at their ends for anchorage.

Hard-Drawn Steel Wire Fabrics

Hard-drawn steel wire fabrics are occasionally used for reinforcing floor slabs, flat and shell roofs etc. These are also used as secondary reinforcement in developing fire resistance and in some precast concrete-like pipes. Square mesh and oblong mesh are also made by welding wire fabrics. Square-mesh fabrics have wires of the same size and spacing in both directions. Oblongmesh fabrics have transverse wires that are smaller and more widely spaced than the main

longitudinal wires.

Rolled Steel Made from Structural

Mild steel bars of grade-I with all nominal sizes mentioned above and grade-II with nominal sizes up to 20 mm have the chemical composition of steel conforming to IS: 226–1975.

Binding Wires

Although binding wires are not reinforcement bars, it has a very important role play in reinforcing works. They are used to bring the two crossing reinforcement bars in a mesh. The available size of binding wire is 20, 18 and 12 SWG which are 0.812, 1.024 and 2.053 mm respectively. The binding wire and other mild steel wire for general engineering use shall be confirmed to IS 280 -2006.

Also, read: Types of Steels and Their Usage in Construction

Storage of Steel Reinforcement Bars

The steel bars are stacked on a raised platform about 0.15 m above the ground level. The platform should be non-metallic and can be made from wooden pallets. Bars of different classifications, sizes and lengths are stored separately. Cement wash (coat) is applied to bars stored for long periods or stored in coastal areas.

Advantages of Steel Reinforcement

- Tension: Steel has a high modulus of Elasticity i.e. 200GPa. This helps the steel to stretch in tension without breaking and regain its shape on removal of load.

- Strength: It is strong enough to withstand the high-impact load.

- Coefficient of Thermal Expansion: Steel and concrete have almost the same coefficient of thermal expansion (change in dimension due to temperatures). Due to this both (concrete and steel) will experience the same length changes in high temperatures.

- Compatibility with Concrete: The fresh concrete is placed on the formwork mould already prepared with reinforcement. The steel reinforcement won’t float in concrete during the concrete placing procedure. Hence, steel reinforcement does not demand special tying up with formworks.

- Robustness of Steel Reinforcement: The steel bars are robust in nature and they can withstand rigours, the wear and tear during construction activities.

- Bent Property of Steel Reinforcement: The steel bars once manufactured to a standard size, can be bent to the required specifications. Hence fabricated steel bars are delivered easily at the site.

- Resistance: Steel is resistant to rough conditions during transport, storage, bundling and placing on the construction site. If minor damage happens, it does not significantly affect its performance.

- Recycling Property: The steel reinforced left over after the service life of a structure is recycled again and used for new construction.

- Easily Available: Every region of a country will have a steel supplier or manufacturer. Hence steel reinforcement is easily available.

Also, read: Structural Steel 101: A Comprehensive Guide To Mastering The Basics And Beyond

Disadvantages of Steel Reinforcement

- Rust: Steel exposed to weather rusts and reduces the strength of reinforced concrete. When rusts start building up around the steel rebars, it causes severe internal pressure on the surrounding concrete, leading to cracks in the concrete.

- High Cost: Steel is expensive and considerably increases the cost of the structure.

- High Temperatures: Steel shows a tendency to melt in extremely high temperatures. This is also one of the reasons; steel is tied and not welded.

- Reaction: Too little concrete cover allows the water to penetrate and react with steel rebars causing the concrete to crack.

- Weight: It is not a lightweight material.

FAQs:

Q: What is steel reinforcement?

Ans: Steel reinforcement is steel bars that are provided in combination with plain cement concrete to make it reinforced cement concrete.

Q: What is the tensile strength of steel?

Ans: The tensile strength of steel is the resistance of steel to breaking under tension. There are three types of tensile strength of Steel: –

1. Yield strength,

2. Ultimate tensile strength and

3. Breaking strength or Tensile strength.

![]()

Thanks for your wonderful article.

I will translate your article into Persian soon and publish it on my blog. ( https://ahanspot.com/ )