There are several types of cracks in asphalt pavement. These types of cracks and defects depend upon the nature of pavement exposed to elements and the load they experience. These cracks and defects are examined and treated by identifying the root problems. Keep reading to see the problems (cracks and defects) and how to repair them.

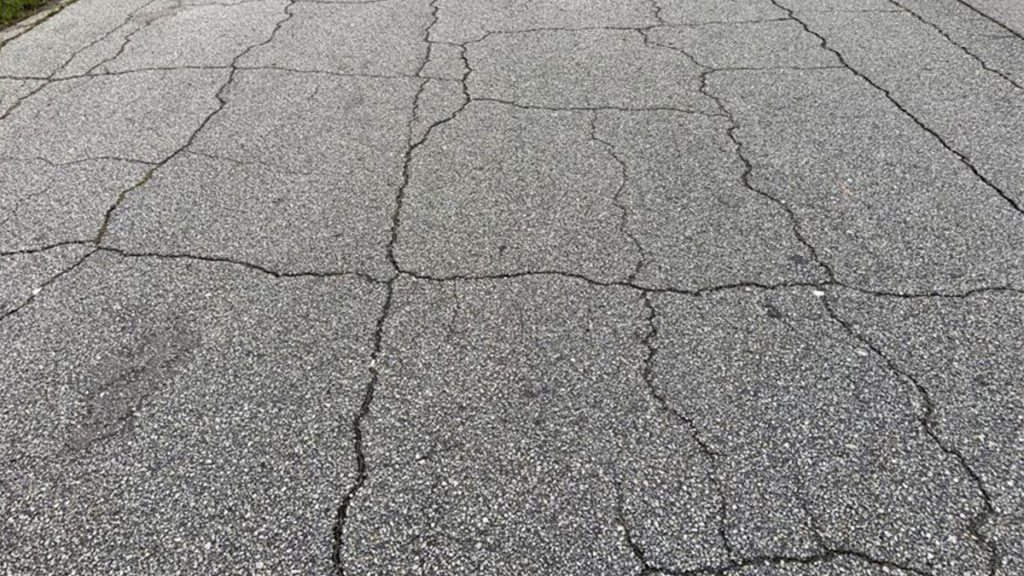

Alligator Cracking

The type of crack observed in asphalt, which resembles the skin or back of an alligator, is commonly referred to as “alligator crack” or “crocodile cracking.” This name is derived from its resemblance to the pattern found on alligator skin. Alligator crack is characterized by interconnected cracks that form a series of small blocks on the surface of the asphalt pavement.

Causes

Alligator cracks occur as a result of one or more of the following factors:

- Excessive deflection of the pavement surface, particularly in the wheel tracks, is caused by an unstable subgrade, sub-base, or base of the pavement. Saturation of the subgrade or lower layers of the pavement can contribute to unstable conditions.

- Due to excessive loads imposed by heavy vehicles on the pavement surface, insufficient pavement thickness, or a combination of both factors.

- Binder brittleness can be attributed to either binder ageing or initial overheating. This brittleness can lead to the formation of fine cracks resembling the pattern on alligator skin. However, in such cases, there is no surface deflection. These cracks are sometimes referred to as “crazing.”

Repairing

The alligator cracking is due to a structural failure and the only possible solution to alligator cracking is to perform a full-depth patch.

Block Cracking

Block cracking is the formation of cracks on the pavement in a rectangular pattern in either direction of the flow of traffic.

Causing

This crack is caused by shrinkage of the asphalt pavement due to the inability of asphalt to expand with the changing temperature. This can be because the mix was mixed and placed too dry; fine aggregate mix with low penetration as[halt and absorption aggregate; poor choice of asphalt binder in the mix design; or ageing dried out asphalt.

Repairing

Cracks in asphalt with less severe measuring up to 1/2 inch or less can be sealed to prevent moisture from entering into the subgrade. More severe cracks should be fixed by removing the cracked pavement layer and replacing it with an overlay.

Longitudinal Cracking

Longitudinal cracking refers to cracks that form in a straight line along the road, running parallel to the pavement’s centerline or the direction of its construction. These cracks can manifest either at the joint between the pavement and the shoulder or at the joint between two adjacent paving lanes.

Cause

Longitudinal cracking can be the result of:

- These cracks in asphalt can be the result of pavement fatigue, reflective cracking, and/or poor joint construction. Joins are generally the least dense areas of pavement.

- The cracking at the pavement shoulder joint may be due to cyclic wetting and drying beneath the shoulder surface owing to poor drainage or due to depressions in the pavement edge which allow water to stand and seep through the joint. Another contributing factor can be shoulder settlement or the passage of trucks over the joint, which can generate stress and ultimately lead to the formation of these cracks.

Repair

Less severe cracks measuring 1/2 inch or less can be sealed to prevent moisture from entering into the subgrade. More severe cracks should be fixed by removing the cracked pavement layer and replacing it with an overlay.

Transverse Cracking

Transverse cracks are single cracks perpendicular to the pavement’s centerline or layout direction.

Causes

Transverse cracks can be caused by reflective cracks from an underlying layer, daily temperature cycles, and poor construction due to improper operation of the paver.

Repair

Less severe cracks measuring 1/2 inch or less can be sealed to prevent moisture from entering into the subgrade. More severe cracks should be fixed by removing the cracked pavement layer and replacing it with an overlay.

Edge Cracks

Edge cracks travel along the inside edge of the pavement surface within one or two feet.

Causes

This type of crack in asphalt pavement is the most common cause for this type of crack in poor drainage conditions and lack of support at the pavement edge. As a result, underlying base materials settle and become weakened. Heavy vegetation along the pavement edge and heavy traffic can also be the instigators of edge cracking.

Repair

The first step in correcting the problem is to remove any existing vegetation close to the edge of the pavement and fix any drainage problems. Crack seal /fill the cracks to prevent further deterioration or remove and reconstruct to full depth fixing any support issues.

Reflection Cracks

These are cracks in a flexible pavement overlay of a rigid pavement (i.e., asphalt over concrete). They occur directly over the underlying rigid pavement joints.

Cause

Joint reflection cracking does not include reflection cracks that occur away from an underlying joint or from any other type of base (e.g., cement or lime stabilisation).

Repair

For less severe cracks (less than 1/2 inch) crack sealing will prevent the further entry of moisture into the subgrade. If the cracks are more severe the removal of the cracked pavement layer followed by an overlay may be required.

Also, read: Traffic Islands: Types and Functionality

Slippage Cracks

Slippage cracks are crescent-shaped cracks or tears in the surface layer(s) of asphalt where the new material has slipped over the underlying course.

Cause

This problem is caused by a lack of bonding between the asphalt layers or because a primer coat was not used to bond the asphalt to the underlying stone base course. The lack of bond can be also caused by dirt, oil, or other contaminants preventing adhesion between the layers.

Repair

All of the areas exhibiting the “stretch marks” will need to be removed and will require a partial or full-depth patch.

Potholes

Small bowl-shaped depressions in the pavement surface penetrate all the way through the asphalt layer down to the base course. They generally have sharp edges and vertical sides near the top of the hole.

Cause

Potholes are the result of moisture infiltration and are usually the result of untreated alligator cracking. As alligator cracking becomes severe, the interconnected cracks create small chunks of pavements, which can be dislodged as vehicles drive over them. The remaining hole after the pavement chunk is dislodged is called a pothole.

Repair

Full-depth replacement patch.

Depressions (bird baths)

Depressions are localized pavement surfaces with slightly lower elevations than the surrounding pavement. Depressions are very noticeable after rain when they fill with water.

Repair

Depending on the severity of the depression the asphalt may have to be removed and replaced (severe one). Less severe depressions can be fixed by applying a thin surface patch or infrared patch.

Corrugation and Shoving

A form of plastic movement typified by ripples (corrugation) or an abrupt wave (shoving) across the pavement surface. The distortion is perpendicular to the traffic direction. Usually occurs at points where traffic starts and stops (corrugation) or areas where HMA abuts a rigid object (shoving).

Causes

Is usually caused by traffic action (starting and stopping) combined with

- An unstable (i.e. low stiffness) HMA layer (caused by mix contamination. poor mix design, poor HMA manufacturing, or lack of aeration of liquid asphalt emulsions)

- Excessive moisture in the subgrade

Repair

A heavily corrugated or shoved pavement should be investigated to determine the root causes of failure. Repair strategies generally fall into one of two categories

- Small, localized areas of corrugation or shoving. Remove the distorted pavement and patch.

- Large corrugated or shaved areas are indicative of general HMA failure. Remove the damaged pavement overlay.

Also, read: Embankment Construction: Materials and Specification

Upheaval Cracks

The type of defect in the asphalt is due to the uplift of the sub-grade of the pavement which is common in the area where the frosting and swelling of the soil is a common issue. Upheaval is a localized upward movement in the pavement due to swelling of the subgrade.

Cause

Due to swelling of the subgrade with the effect of moisture or frost heave (ice under the pavement).

Repair

As this is the issue with the asphalt upheaval stem in the pavement subgrades, treatments like a crack seal and seal coating are not sufficient and are not recommended. Therefore, the best way to repair upheaval is to dig out the affected area of the pavement and base and then replace it with a full patch.

Raveling (very porous asphalt)

Ravelling is the ongoing separation of aggregate particles in a pavement from the surface downward or from the edges inward. Usually, the fine aggregate wears away first and then leaves little “pockmarks” on the pavement surface. As the erosion continues, large and larger particles are broken free and the pavement soon has then rough and jagged appearance typical of surface erosion. There are many reasons why ravelling can occur, but one common cause is placing asphalt too late in the season. This is because the mixture usually lacks warm weather traffic which reduces pavement surface voids, further densification, and kneading of the asphalt mat. For this reason, ravelling is more common in the more northern regions (snow belt).

Repair

Apply a thin hot-mix overlay. Other solutions could include sand seal, chip seal, slurry seal or micro-surfacing.

Also, read: Joints in Concrete Pavements: Transverse Joints & longitudinal joints

![]()

Phew! It was such a relief to find out that we can avoid edge cracks from affecting our asphalt by getting rid of any plant next to it. I’ve been spotting something weird with the street right in front of my house but I couldn’t really pinpoint it yet. Maybe I should just hire a professional to resolve this issue once and for all.

You definately should do it.