The type of connection chosen influences member design, necessitating early decision-making in the structural system’s design process. While connections are categorized into idealized types during design, the actual behaviour may differ, demanding constant awareness to align the designed connection with its intended type. Connection elements, including cleats, gusset plates, and various connectors, contribute to the classification of connections into riveted, bolted, and welded types. Riveted connections, once popular, are gradually giving way to bolted connections due to factors such as low rivet strength and higher installation costs.

What is A bolt?

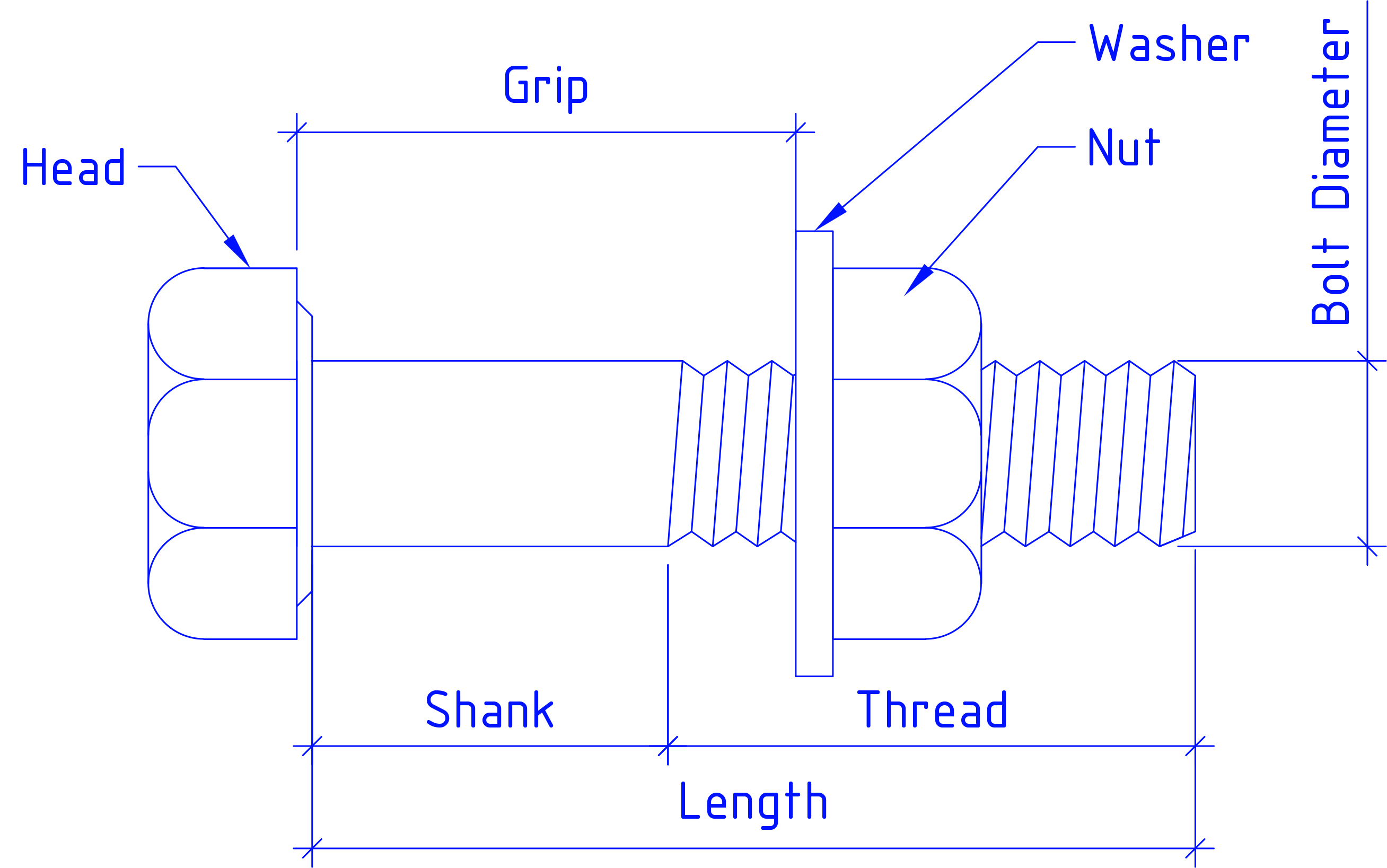

A bolt is a type of fastener that is designed to mechanically join two or more unthreaded components together. It consists of a threaded cylindrical shaft with a head at one end. The head is usually larger than the diameter of the shaft and provides a surface for applying torque during installation or removal. The other end of the bolt is typically threaded to allow it to be screwed into a nut.

- Bolts: These are cylindrical fasteners with threaded ends that pass through holes in the connected elements. Bolts come in various sizes and materials, and their strength is crucial for the overall integrity of the connection.

- Nuts: Nuts are threaded components that are screwed onto the bolts to secure them in place. They play a critical role in maintaining the tightness and stability of the connection.

- Washers: Washers are flat disks typically placed under the head of the bolt or between the nut and the connected element. They help distribute the load and prevent damage to the surfaces being connected. They are provided under the bolt as well as under the nuts to serve two purposes.[1]

- to distribute the clamping pressure on the bolted member, and

- to prevent the threaded portion of the bolt from bearing on the connecting pieces.

Types Of Bolts

There are different types of bolts commonly used to connect structural elements. Two commonly used types are unfinished bolts and high-strength bolts.

Also, read: 4 Types Of Bolt Holes And Their Specification According To AISC

Unfinished Bolts

Unfinished bolts also known as ordinary, common, rough, or black bolts, are typically used for light structures under static loads for secondary members such as purlins, bracings, etc., and roof trusses. They are not recommended for connections subjected to impact load, vibration and fatigue.

Ordinary structural bolts are made from low-carbon rolled steel circular rods, allowing for larger tolerance and are with square or hexagonal heads. The bolts are available from 5 to 36 mm in diameter and are designated as M5 to M36. However, in structural steelwork, the most common ones are M16, M20, M24 to M30.

| Bolt Size, d (mm) | (12) | 16 | 20 | (22) | 24 | (27) | 30 | 36 |

|---|---|---|---|---|---|---|---|---|

| Tensile Stress Area (mm2) | 84.3 | 157 | 245 | 303 | 353 | 459 | 561 | 817 |

High-Strength Bolts

These high-strength bolts have replaced rivets and conventional black bolts, finding widespread application in various structures, including high-rise buildings, bridges, and machinery. Their adoption is driven by the superior performance and reliability they offer in demanding construction scenarios.

High-strength bolts, ranging in sizes from 16 to 36 mm, are categorized as M16, M20, M24, and M30, each bearing a property class identification symbol embossed on the bolt head, such as 8S, 8.8S, 10S, or 10.9S. In this context, ‘S’ denotes high strength. Among these, the widely utilized bolts belong to the 8.8S and 10.9S property classes.

In the United States, two commonly specified groups of high-strength bolts for steel structures are Group A and Group B. Group A includes A325 bolts with an ultimate strength of 120 ksi, while Group B includes A490 bolts with an ultimate strength of 150 ksi.

Also, read: Types Of Steels And Their Usage In Construction

What is a bolted connection?

Bolted connection is a technique used to join structural components using bolts. Compared to other types of connections used for forming structural joints, bolted connections are more prevalent. The process for establishing a bolted connection involves overlapping the members to be connected, drilling bolt holes on the overlapped portion, inserting bolts into the hole with washers at their position, inserting nuts in the shank portion, and tightening them with the help of spanners. As a result of tightening the nut, clamping action is developed in the bolts, which are transferred to plates with the help of washers.

Types of Joint By Bolted Connection

Bolts in steel structures create two distinct types of joints: the lap joint and the butt joint.

- Lap Joint: In a lap joint, the components overlap, and bolts secure them together. This joint is characterized by an overlapping arrangement, which adds strength and stability to the connection. In a lap joint, the load lines of the two members do not coincide. This results in an eccentricity that creates unwanted bending, causing tension in the bolt. This tension can ultimately cause the bolt to fail.

- Butt Joint: On the other hand, a butt joint involves the abutment of two components with the bolts connecting them at their ends. This type of joint is known for its flush connection, where the ends of the components meet, providing a seamless appearance and structural continuity.

In a lap connection, there is a difference in the positions of the load’s centre of gravity in one connected member and the load’s centre of gravity in another connected member. This leads to unwanted bending. However, the double-cover butt connection avoids this issue by eliminating moments and ensuring zero eccentricity. Furthermore, the shear strength of each bolt in a double-cover butt connection is twice as high as the shear strength of each bolt in a lap connection or a single-cover butt connection.

classification Of Bolted Connection

The classification of bolted connections is based on several factors, each influencing the overall strength and performance of the connection. Here are key aspects of the classification:

Based On The Resultant Force Transferred:

There are two categories of bolted connections based on the line of action of the resultant force transferred:

- Concentric connections: These connections occur when the line of action of the resultant force passes through the centre of gravity of the bolted connection.

- Eccentric connections: These connections occur when the line of action of the resultant force does not pass through the centroid of the bolted connection.

Based On Force Experienced By The Bolts:

Bolted connections can be classified into three categories based on the type of force experienced by the bolts:

- Tension connections: Bolts resist forces acting away from each other. Tension connections are crucial in scenarios where axial loads are a significant design consideration.

- Shear connections: Bolts primarily resist forces parallel to the plane of the connected elements. Shear connections are common in applications where lateral forces are predominant.

Based On Force Transfer Mechanism by Bolts:

Connections are referred to as bearing type—bolts bear against the holes to transfer the force, e.g., slip-type connections; and friction type—when the force is transferred by friction between the plates due to tensioning of bolts, e.g., slip-critical connections.

- Bearing connection: Bearing-type connections rely on the bolts’ ability to bear compressive forces through the connected elements. The load is transferred by the direct contact of the bolt with the material, distributing the force across the bearing area.

- Friction mechanism: Friction-type bolted connections, depend on the resistance to sliding between connected surfaces. Bolts are tightened to a specified torque, creating sufficient friction to prevent relative motion between the connected elements.

Also, read: Comprehensive Guide To Tension Members In Steel Structure

Advantages of Bolted Connection

- The construction process can be expedited by opting for bolted structures.

- It requires less skilled labour, contributing to a faster and more cost-effective erection.

- In comparison to riveted construction, bolted construction is economically advantageous due to lower labour and equipment expenses and the need for a smaller quantity of bolts to withstand the same load.

Disadvantages of Bolted Connection

However, there are notable drawbacks to using bolts:

- The material cost is relatively high, approximately double that of rivets.

- The tensile strength of bolts decreases due to area reduction at the thread root and stress concentration.

- Bolts typically have a loose fit, except for turned bolts, which can result in reduced strength.

- Vibrations or shocks may cause bolts to become loose.

Also, read: Advantages And Disadvantages Of Welded Joints

Summary:

It’s important to note that there are other types of bolts used in steel structures, such as precision bolts and high-tension bolts. However, the unfinished bolts and high-strength bolts mentioned earlier are commonly used in various structural applications.

Also, read: Types Of Loads On Building

FAQs

Q: What forces need to be taken into account when designing a bolted connection?

Answer: When designing a bolted connection, it is essential to consider various forces that may act on the structure. These forces include tension, shear, compression, and moments.

Q: What is the purpose of a washer in a bolted connection?

Answer: Washers distribute the load and prevent damage to the connected materials. They also help to maintain proper tension in the bolt by providing a smooth surface.

Q: How do I determine the appropriate bolt size for a connection?

Answer: Bolt size is determined based on the load and the type of connection. Engineers use standard tables and formulas considering material strength and safety margins.

References:

- [1] [2] [3] Duggal,.S.K. (2014). Limit State Design of Steel Structures (2nd Edition). McGraw Hill Education (India) Private Limited

- Lin., W. & Yoda., T. (2017). Bridge Engineering. Classifications, Design Loading, and Analysis Methods https://www.sciencedirect.com/book/9780128044322/bridge-engineering#book-description

- Ochshorn, J. (n.d.). Steel: Jonathan Ochshorn’s Structural Elements text, Third Edition. © 2020 J. Ochshorn. https://jonochshorn.com/structuralelements/book/4.08-connections.html

- Gowda, H. T. S. (n.d.). Design of bolted connections in steel structures. Scribd. https://www.scribd.com/document/134342466/Design-of-Bolted-Connections-In-Steel-Structures

![]()