Concrete Admixture can alter the physical and chemical properties of concrete or mortar for specific functions. With several types of admixtures available, this article aims to discuss their application in concrete works.

Concrete Admixture

Concrete admixtures are substances other than cement, aggregates, water and reinforcement to enhance performance based on specific requirements of the concrete. Typically, the amount used does not exceed 5% of the cement mass, except in special cases. Admixtures are classified according to their primary functions and generally include water-reducing agents, air-entraining agents, hardening accelerators, set retarders, flash-setting agents, expanding agents, antifreeze agents, rust-resistant agents, and others.

As per ACI it is defined as, “a material other than water, aggregates, cementitious materials, and fibre reinforcement, used as an ingredient of a cementitious mixture to modify its freshly mixed, setting, or hardened properties and that is added to the batch before or during its mixing.”

Types of Concrete Admixtures

- Water Reducing Admixtures

- Retarding Admixtures

- Accelerating Admixtures or Accelerator

- Air-entraining concrete admixture

- Air detraining Admixtures

- Grouting Admixtures

1. Water Reducing Admixtures

They are used to minimize the water demand in a concrete mix. Water-reducing admixtures increase the workability and strength of concrete, good bond between concrete and steel, and prevent cracking, segregation, honeycombing and bleeding. Based on raw materials and chemical composition, it can be divided into lignosulphonate, alkyl aryl sulphonate (known as coal tar water-reducing admixture), melamine water-reducer, molasses and humic aid water reducer, etc.

Based on the performances and functions, water-reducing admixture can be divided into ordinary water-reducer, effective water-reducer, hardening water-reducer, retarder water-reducer and air entrain water-reducer. It is a type of surfactant that has a hydrophilic group and hydrophobic ground of molecules.

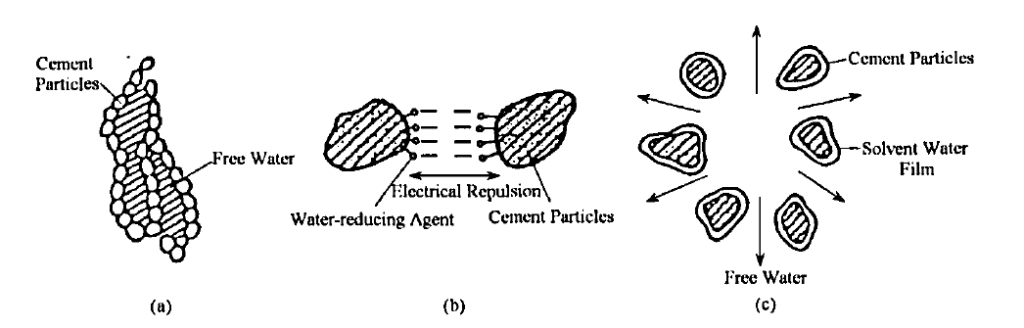

When concrete is mixed with water, the cement paste forms a flocculated structure due to the cohesion between cement particles [see Figure 1(a)]. Some of the mixing water becomes trapped within this structure, reducing the mobility of the concrete mix. However, when a water-reducing admixture is added, its hydrophobic groups attach to the surface of the cement particles, giving them the same charge. This causes the particles to repel each other due to electrical repulsion [see Figure 1(b)], releasing trapped water from the flocs and increasing mobility without adding extra water. Additionally, the water-reducing admixture forms a layer of solvent water film [see Figure 1(c)], acting as a lubricant between the cement particles, further improving mobility.

Also, read: Portland Cement: Properties, Composition, Types and Uses

2. Retarding Admixtures or Set Retarder

Retarding admixtures are used to slow down the initial setting time of concrete. Due to this, they are generally used in hot weather or high-temperature conditions, and long transport distances to prevent the loss caused by the early slump of concrete mix. They don’t have a bad impact on the development of concrete strength at the latter stage.

There are two types of retarding admixtures which are organic retarders and inorganic/chemical retarders.

3. Accelerating Admixtures or Accelerator

Accelerating admixtures refers to the agent that can accelerate the development of early strength of concrete or it can increase the rate of hydration of hydraulic cement, shorten the setting time of concrete and increase the rate of early strength development of concrete. Some of the applications of accelerating admixtures are in cold weather concreting, rigid pavement construction and prefabricated structures. It is especially used in winter construction where the temperature is less than -5 °C and emergency repair work.

Generally, accelerating admixtures are of three categories that can be divided into inorganic, organic and inorganic-organic compounds.

4. Air-Entraining Admixtures

Air-entraining admixtures are admixtures that cause the development of microscopic air bubbles in concrete while mixing. This increases its resistance to freezing and improves the workability and durability of concrete. It is a kind of surfactant which can influence the concrete as follows:

- Improve the workability of concrete mixtures: Closed bubbles act like small balls, reducing friction between cement particles, which improves the concrete’s mobility. At the same time, the bubble film helps conserve water, aiding in better hydration of the cement.

- It can enhance impermeability and frost resistance: It leads to closed stomata in concrete thereby cutting off the capillary porosity ducts and reducing pores thereby enhancing impermeability.

- It can reduce the strength of concrete: If the air content in concrete is increased by 1%, its compressive strength can decrease by 4% to 6%.

5. Superplasticizer Admixture

When added to concrete or mortar, it imparts very high workability or allows a significient decrease in water content for a given workability.

Also, read: What is The Water-Cement Ratio?: Calculation and Value of Water Cement Ratio.

5. Pozzolanic Admixtures

Pozzolanic Admixtures are also known as mineral admixtures since they are derived from other substances and are not chemically manufactured. Pozzolanic Admixtures affect the properties of concrete in both plastic and hardened state. One property of pozzolanic admixtures is they react/hydrate with cement therefore they are also called supplementary cementing materials. Examples of pozzolanic admixtures are silica fume, fly ash, blast furnace slag etc.

FAQs:

Q: How do admixtures affect the setting time of concrete?

Ans: Certain admixtures can either accelerate or retard the setting time. Retarding admixtures is used to slow down the setting, which is helpful in hot weather or complex projects with longer transportation or finishing times. Accelerating admixtures are used to speed up the setting process, which is beneficial in cold weather or when early strength is required.

Q: What is the dosage rate for admixtures?

Ans: The dosage rate varies depending on the type of admixture and the specific needs of the project. Manufacturers typically provide recommended dosages, which should be followed carefully. It’s important not to exceed these limits as improper dosage can affect concrete performance

References:

- Zhang, H. (Ed.). (2011). Building Materials in Civil Engineering (1st ed.). Woodhead Publishing Limited. https://shop.elsevier.com/books/building-materials-in-civil-engineering/zhang/978-1-84569-955-0

- Bureau of Indian Standards. (1999). Concrete Admixture. (IS 9103: 1999) (1st Rev.). Bureau of Indian Standard (BIS).

![]()