Have you thought of constructing a fire-resistant building? Do you need to protect your home from fire disasters? Yes, indeed, it is essential to protect your home from fire disasters as you pay a huge amount of money to build it or buy it. Or for the matter, if you sell it your home needs to be fire-resistant.

Building Classifications As Per IBC

The International Building Code (IBC) classifies building construction into five basic types based on the degree of fire resistance of various structural components of the building. These classifications are known as Types I, II, III, IV, and V.

The fire resistance of a building’s structural components is an important factor in protecting occupants and property from the spread of fire. The IBC classifications are based on the fire resistance of the building’s construction materials, including floors, roofs, walls, columns, and beams.

The five types of building construction classifications are:

- Type I: Buildings with a high degree of fire resistance, including both protected and unprotected noncombustible construction. This type includes buildings made of steel or concrete, such as high-rise office buildings, hospitals, and government facilities.

- Type II: Buildings with a moderate degree of fire resistance, including protected noncombustible construction. This type includes buildings made of steel or concrete with fire-resistive materials, such as sprayed-on fireproofing, and may also include some types of heavy timber construction.

- Type III: Buildings with a moderate degree of fire resistance, including protected combustible construction. This type includes buildings with exterior walls made of noncombustible materials, such as masonry, but with combustible interior framing and finishes, such as apartments and hotels.

- Type IV: Buildings with a high degree of fire resistance, including heavy timber construction. This type includes buildings with large timber elements, such as exposed beams and columns, but with noncombustible or limited combustible exterior walls and roofs.

- Type V: Buildings with a low degree of fire resistance, including wood-frame construction. This type includes buildings with exterior walls, floors, and roofs made of combustible materials, such as residential homes and some commercial buildings.

Fire-Resistant Building Construction

In a fire-resistant construction, the design should be such that the components can withstand fire as integral members of the structure, for the desired period. We shall consider the construction of the following components:

- Walls and columns

- Floors and roofs

- Wall Opening

- Escape elements

- Strong room construction

Walls and columns

The following points should be observed for making walls and columns fire-resistant:

- Masonry walls and columns should be made of thicker sections so that they can resist for a longer time, and can also act as a barrier against the spread of fire to the adjoining areas.

- In the case of solid load-bearing walls, bricks should be preferred to stones.

- If walls are to be made of stones, granite, and limestone should be avoided.

- In the case of a building with a frame structure, R.C.C. should be preferred to steel.

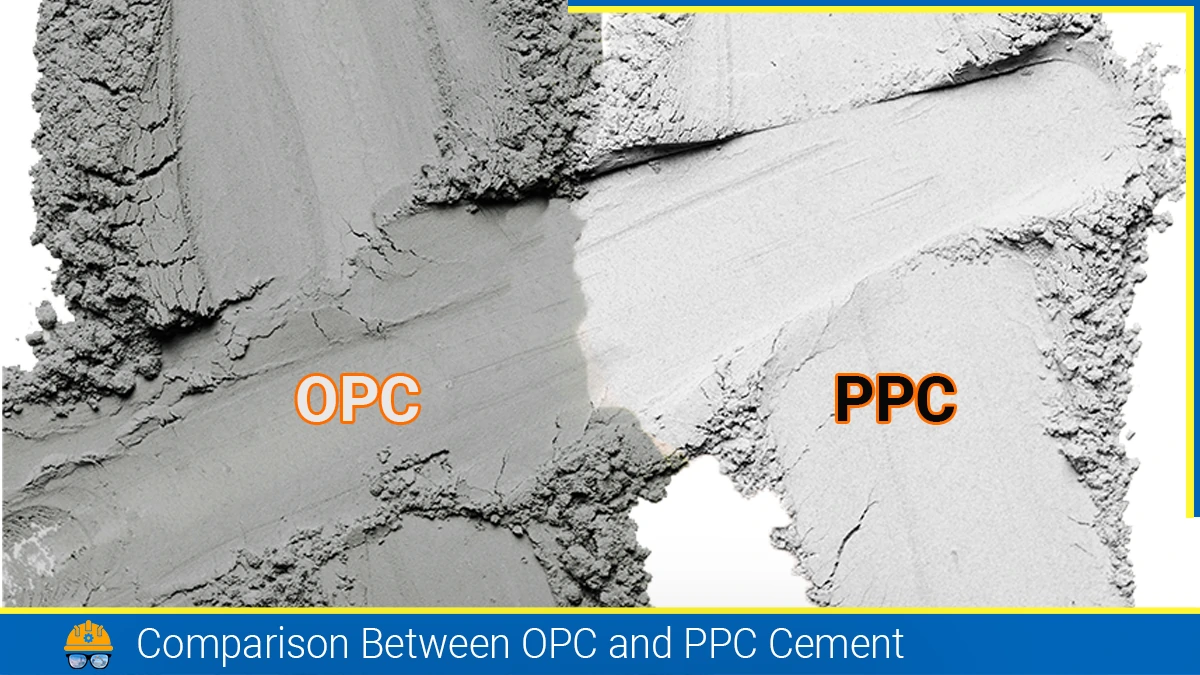

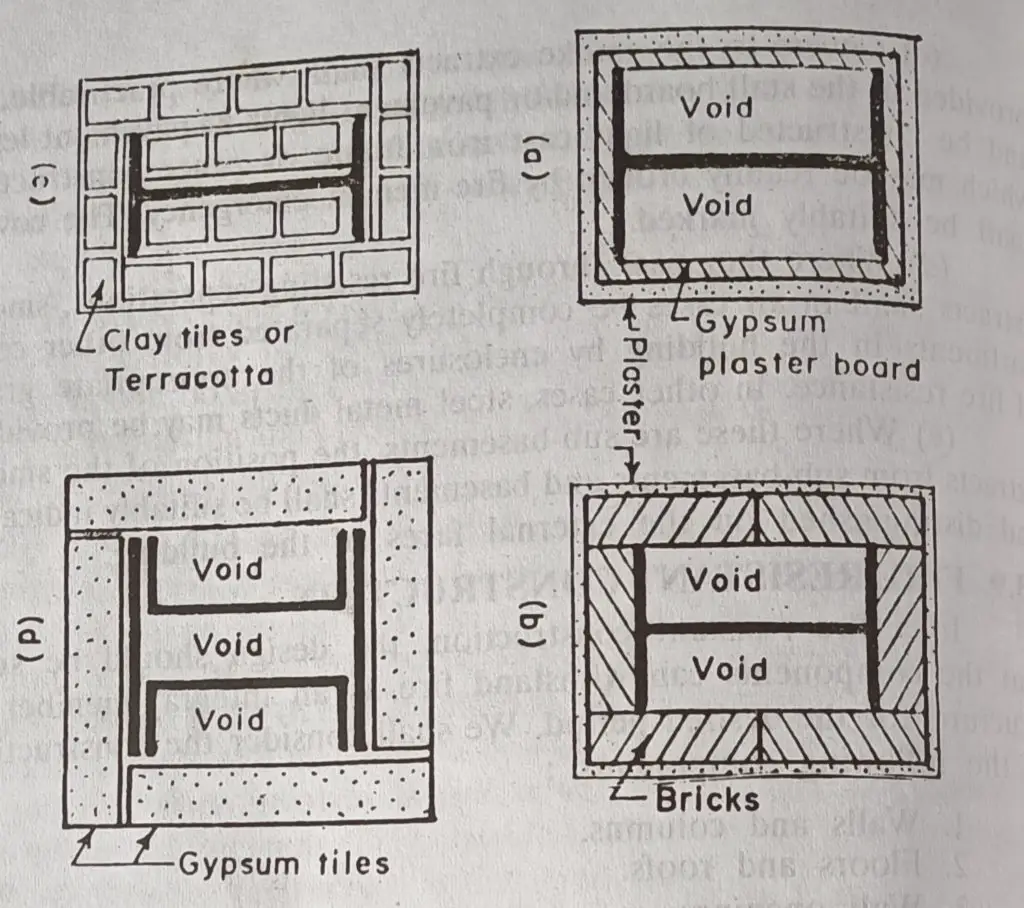

- If steel is used for the framed structure, the steel structural components should be properly enclosed or embedded into concrete, terracotta, brick, gypsum plasterboard, or any other suitable material, as illustrated in the figure below.

- If the framework is of R.C.C. thicker cover should be used so that the members can resist fire for a longer time. It is recommended to use a 40 to 50mm cover for columns, a 35 to 40 mm cover for beams and long-span slabs, and 25mm for short-span slabs.

- Partition walls should be of fire-resistant materials such as R.C.C. reinforced brickwork, and hollow concrete blocks. burnt clay tiles, reinforced glass, asbestos cement board, or metal laths covered with cement plaster.

- Cavity construction has better fire resistance.

- All walls, whether load-bearing or non-load bearing should be plastered with fire-resistive mortar.

Floors and Roofs

The following points are noteworthy for fire-resistant floors and roofs:

- For better fire resistance, a slab roof is preferred to sloping or pitched roofs.

- If it is essential to provide sloping rood, trusses should either be of R.C.C. or of protected rigid steel with fireproof covering.

- For better fire resistance, the floor should be either of R.C.C or of hollow tiles ribbed floor or of concrete jack arch floor with steel joists embedded in concrete.

- If the floor is made of timber (timber flooring), thicker joists at a greater spacing should be used, and fire stops or barriers should be provided at a suitable interval.

- Flooring materials like concrete tiles, ceramic tiles, bricks, etc. are more suitable for fire resistance.

- If cast iron, wrought iron, cork carpet, rubber tiles, etc. are to be used, these should be protected by a covering of insulating materials like ceramic tiles, plaster, terracotta, bricks, etc.

- The ceiling, directly suspended from the floor joist should be of fire-resistant materials like asbestos cement boards, fiberboards, metal lath with plaster, etc.

Wall Openings

- From the point of view of fire spread, openings in the wall should be a bare minimum.

- Openings serve means of escape. Hence these should be properly protected by suitable arrangements, in case of fire.

- Doors and windows should be made of steel. Fire-resistant doors can be obtained by fixing steel plates on both sides of the door.

- Wire glass panels are preferred for windows.

- Rolling shutter doors should be used for garages, godowns, shops, etc.

- In the case of timber doors, the minimum thickness of the door leaf should be 4cm and that of the door frame as 8 to 10cm.

- All escape doors should be such as to provide free circulation to the persons in passages, lobbies, corridors, stairs, etc., and should be made of fireproof materials.

Escape elements

- All escape elements, such as staircases, corridors, lobbies, entrances, etc. should be constructed of fire-resistant materials.

- These escape elements should be well separated from the rest of the building.

- Doors to these escapes should be fireproof.

- The staircase should be located next to the outer wall and should be accessible from any floor in the direction of flow towards the exits from the building.

- Fireproof doors to the emergency staircase should be fixed in such a way as to make them close from the inside only.

- The lift shafts connecting various floors should be surrounded by the enclosure walls of fire-resisting materials.

- Lift shafts should be vented from the top to permit the escape of smoke and hot gases.

- An emergency ladder should be provided in the fire-resisting building. This ladder should be at least 90cm wide and constructed of fire-resistant materials.

- All escape routes over roofs should be protected with railings, balustrades, or parapets not less than one meter in height.

Strong room construction

A strong room construction is found to be useful in the case of safe deposit vaults in banks. The following are the important features of construction.

- The walls floors and ceilings of a strong room are made of at least 30cm thick cement concrete. If thin R.C.C. walls are used, they should have a covering of bricks or terracotta and then be suitably plastered with fire-resistant plaster.

- Doors and windows are well anchored to concrete walls by steel holdfast longer in length.

- Doors and windows should be fireproof. It is preferable to have a double fireproof door.

- Windows and ventilators should be covered by special grills made of 20mm steel square bars. These frills should be well fixed to concrete walls by means of long steel holdfasts.

Fire Alarms

Fire alarms are installed to give an alarm and to call for assistance in event of a fire. The fire alarms give enough time for the occupants to reach a safe place. Fire alarms can be either manual or automatic.

1. Manual alarms

These are of a hand-bell type or similar other sounding devices, which can emit a distinctive sound when struck. These are sounded by watchmen and the occupants are thereby warned to have a safe exit in the shortest possible time. Manually operated alarms shall be provided near all main exits and in the natural path of escape from fire, at readily accessible points which are not likely to be obstructed.

2. Automatic alarms

These alarms start sounding automatically in the event of a fire. It is used in large industrial buildings which may remain unoccupied during the night. The automatic fire alarm sends an alarm to the nearest control point. The system can also perform the function of sending a message to the nearest fire brigade station.

Fire Extinguishing Equipment

Each building should have a suitable fire extinguishing arrangement, depending upon the importance of the building and the associated fire hazards. Following are the usual types of equipment required for fire extinction.

1. Manual Fire Extinguishing Equipment

These devices are useful for extinguishing a fire as soon as it starts. They are not so useful when once the fire has spread. Under this category comes the portable extinguishers of carbon dioxide type or foam generation type, etc. The discharge from a portable fire extinguisher lasts only for a short duration of 20 to 120 seconds. In some cases, especially in small buildings buckets of water, sand, and asbestos blankets are installed at convenient locations for taking care of fires of minor size.

2. Fire Hydrants

These fire hydrants are provided on a ring main of 150mm dia. in the ground around the building periphery. The ring main gets water from the underground tank with pressure, so that available pressure at each hydrant is of the order of about 3.5 to 4kg/cm2.

3. Wet Riser system

The system consists of providing 100 to 150mm dia. vertical G.I pipes (riser) at suitable locations in the building. A fire pump is used to feed water from the underground tank to these pipes, to ensure a pressure of 3kg/cm2 at the uppermost outlet.

4. Automatic Speinkler System

This arrangement is adopted for important structures like textile mills, paper mills, etc. The system consists of a network of pipes 20mm dia. fixed to the ceiling of the room. These pipes are spaced at 3m centre to centre. Heat-actuated sprinkler heads are fixed to these pipes at regular intervals. The pipes get supplied from a header. Each sprinkler head is provided with a fusible plug. In the event of a fire, the fusible plug in the sprinkler nearest to the wire melts due to the rise of temperature, and water gushes out of the sprinkler head. The fire is thus brought under control in a short period.

Also, read:

- Types of Stone Masonry Works | Rubble Masonry

- Stabilized Mud Block: Properties, Advantages & Usage

- What is Lime Mortar?

![]()