Shuttering or formwork is a temporary structure constructed to pour freshly prepared concrete to form the desired shape of the structural elements such as column, beam or slab. Formwork is commonly used for reinforced concrete work including the construction of dams, and bridges. buildings, and many other civil engineering structures. However, it is also not limited to some of the small structures like drain works, catch pits, guard stones, etc. The following are some of the areas where shuttering or formwork is needed:

Formwork for Footings

The first step for any concrete construction starts with the construction of the foundation. The foundation can be for columns or walls. So, based on the type of structural member, the shape and size of the footing are designed. Thus formwork size and shape depend on the type and dimension of the footing.

Components of Footing Formwork

- Wooden pegs

- Wooden panels

- Batten

- Spreader

- Wales

Shuttering for Columns

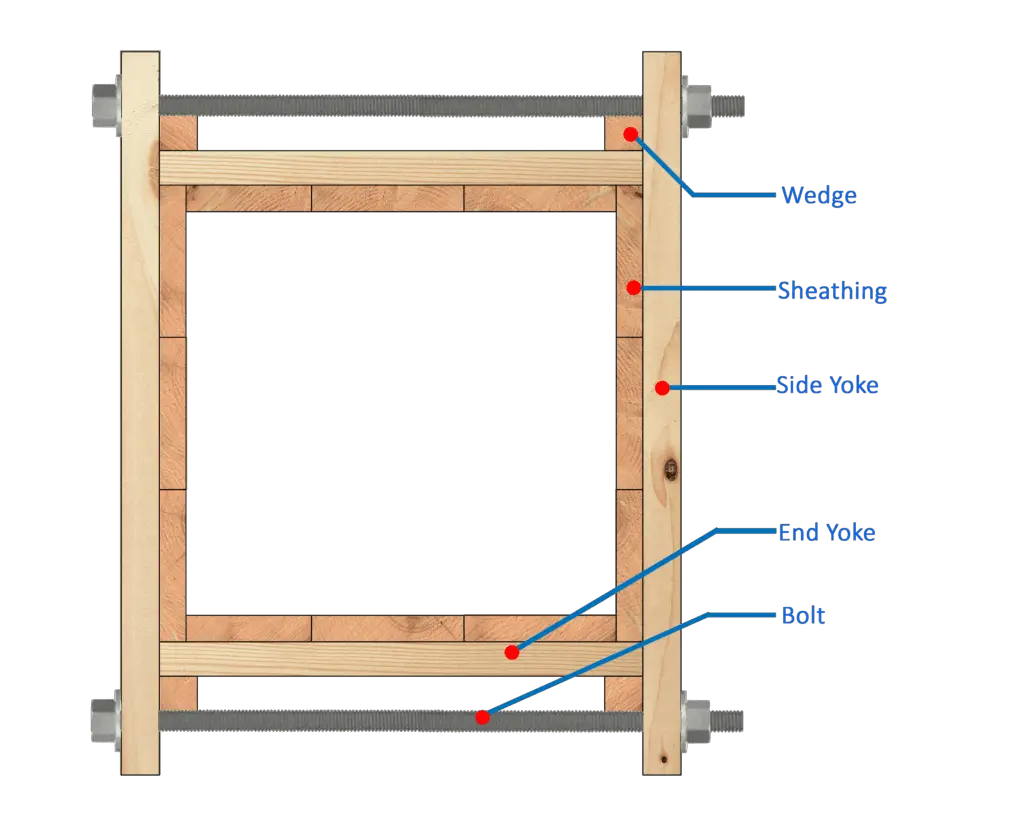

The column is a structural member which transfers all load from the superstructure to the foundation. Due to its smaller cross-section and greater height, it is subjected to lateral pressure. When the concrete is poured into the formwork of the column it exerts lateral pressure outward to the side of the sheathing. Thus it has to be tied properly with recommended bolts.

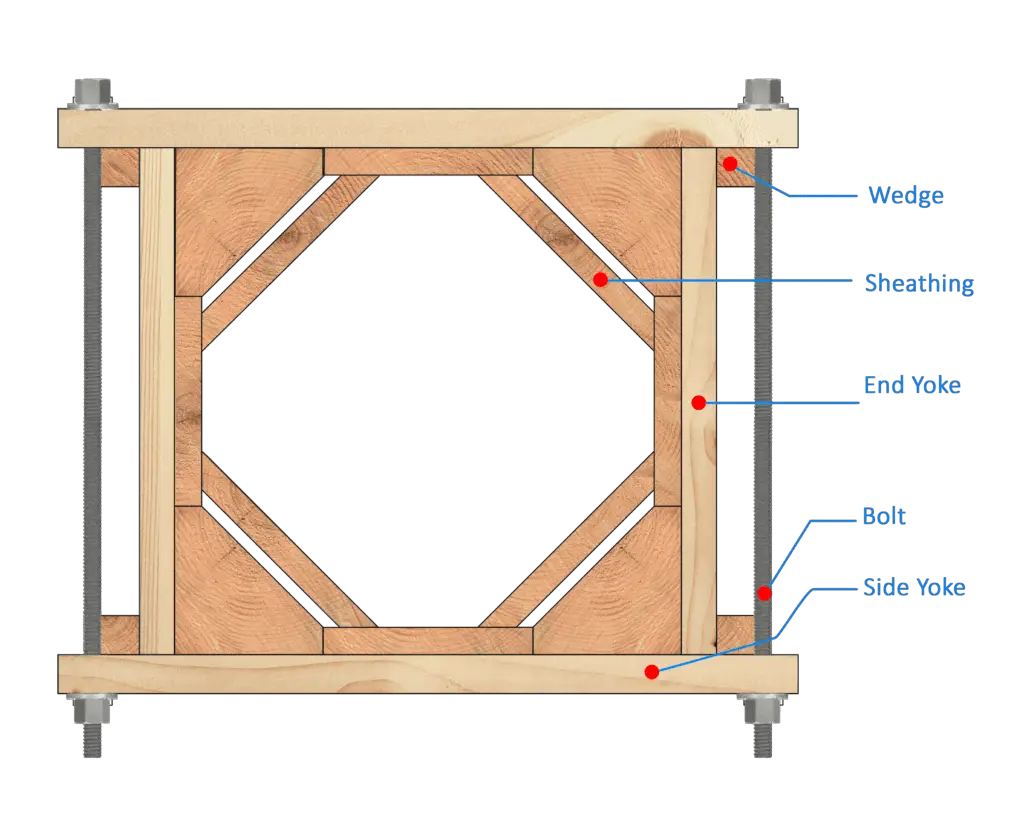

Components of Column Formwork

The shuttering for the column is probably the simplest. It consists of: –

- Sheeting all around the column periphery

- Side yokes and eyes

- Wedges

- Bolts and washers

The side yokes and end yokes consist of two numbers each and are suitably spaced along the height of the column. The two-side yokes are comparatively of heavier section and are connected together by two long bolts of 16mm dia. Four wedges, one at each corner are inserted between the bolts and the end yokes. The sheathing is nailed to the yokes.

Also, read: Types Of Loads On Building

Shuttering for Beam and Slab floor

For the plinth or ground floor beams are cast alone where the slab is not provided in the usual case. For that matter, beam shuttering is provided. However, the beam and floor slab are cast monolithically as they go above the ground floor. Even in the case of concrete bridges, the concrete girder and bridge deck are cast monolithic, which requires the fabrication of shuttering as a single component.

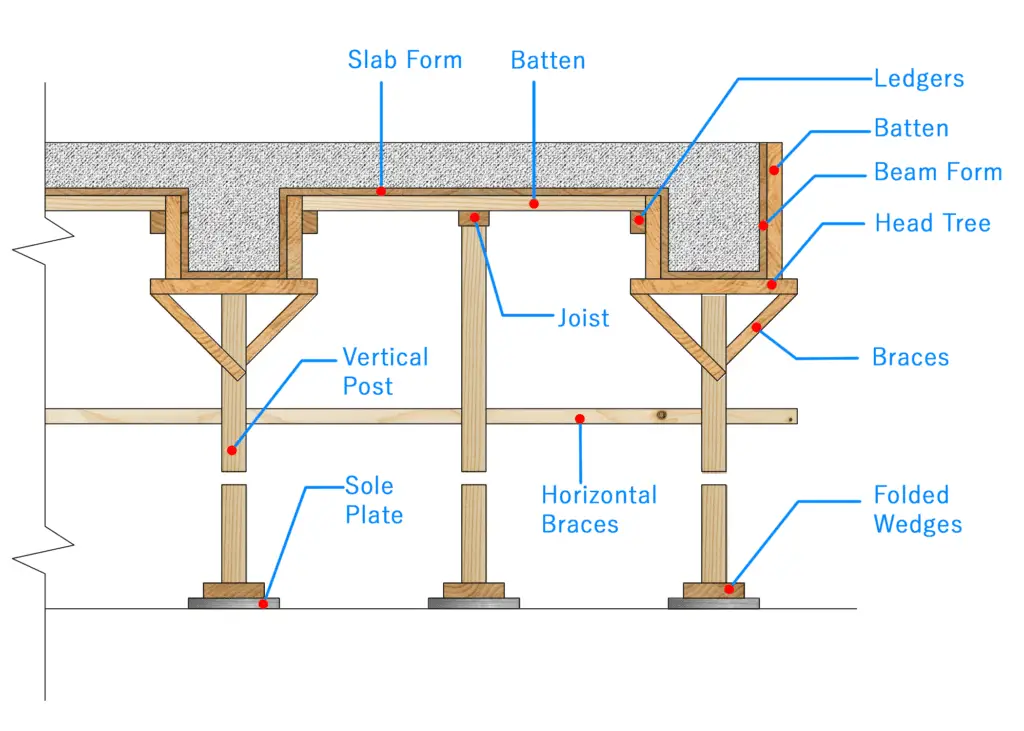

Components of Beam and Slab Floor Formwork

Formwork for beam and slab consists of: –

- Sole plates

- Wedges

- Props

- Head tree

- Planks

- Batten

- Ledger

The slab is continuous over a number of beams and supported on 25mmm thick sheathing laid parallel to the main beams. The sheathing is supported on wooden battens which are laid between the beams, at some suitable distance. In order to reduce deflection, the battens may be provided at the middle of the span through joists. The side of the beam form is of 30mm thick sheathing. The bottom sheathing of the beam form may vary from 50 to 70mm thick. The end of the battens is supported on the ledger which is fixed to the cleats throughout the length.

Cleats 10cm X 20mm to 30mm are fixed to the side forms at the same spacing as that of the battens, so that battens may be fixed to them. The beam form is supported on the head tree. The post or shore is connected to the head tree by edges or post cleats. At the base of the share, two wedges of hardwood are provided in one piece.

Also, read: Removal Of Formwork | Stripping Of Formwork

Formwork for Stair

The shuttering or decking for the deck slab is carried on cross-joist which are in turn supported on raking ledgers. The ledger is generally 75mm X 100mm in size. The cross-joist may be of 50mm X 100mm size suitably spaced. The riser planks are 40 to 50mm thick and equal to the height of the riser. These planks are bevelled at the bottom to permit the whole of the tread face to be travelled. The riser planks are placed only after the reinforcement has been fixed in position.

The outer end of the risers is carried by a cut string made of a 50mm thick plank. The cut string is strutted to the cross-joists by 50mm X 100mm hangers secured to a 50mm thick board fixed to or strutted against the wall. The treads are left open to permit concreting and compacting with vibration. A stiffener joist of 50mm X 100mm is placed along the middle of the riser planks. The stiffener is wired to cross-joist through the decking.

Formwork for Walls

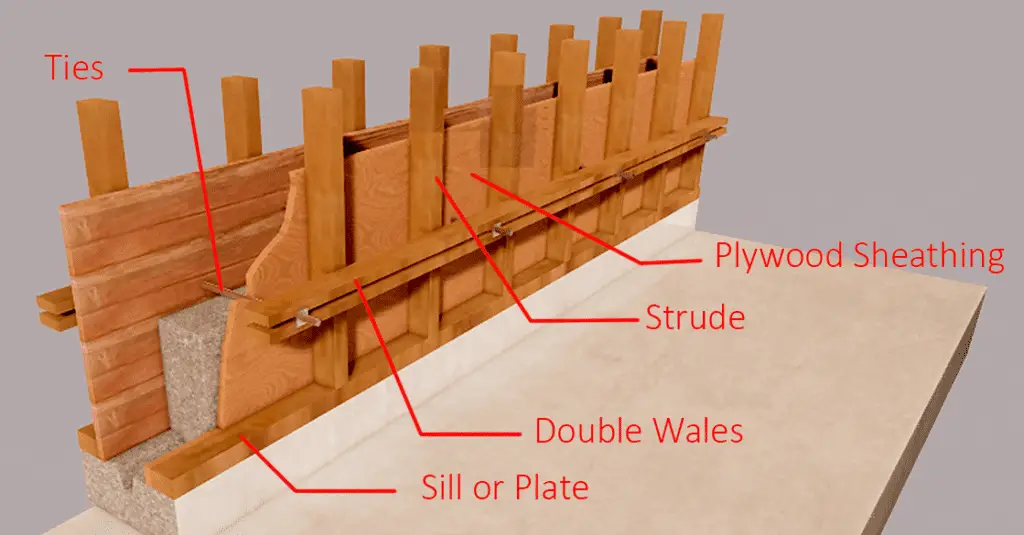

Type 1.

The boarding may be 40mm to 50mm thick for walls up to 3 to 4m in height. The boards are fixed to 50mm X 100mm posts, known as studs or soldiers, spaced about 800mm apart. Horizontal walling of size 75mm X 100mm is fixed to the posts at a suitable interval. The whole assembly is then strutted as shown using 75mm X 100mm struts. The two shutters are kept apart equal to the thickness of the wall, by providing a 50mm height concrete kicker at the bottom and by 25mm X 50mm spacers nailed to the posts.

Type 2

In this type, the forms are made up of a panel size of 600mm X 1800mm so that handling and stripping are easier. A 15 mm plywood is commonly used instead of boarding. The panels are erected in such a way that the lower panels can be removed when concrete is hard and used higher up the wall. Forming of size 50mm X 100mm is used to ply the shutter. The panels are fixed to a central and two end studs. Each stud consists of two pieces of timbers, 50mm X 150mm, blocked apart. The end strut of each panel secures the adjacent panel. Boards are reversed for the first lift; for the succeeding lift, bolts pass through holes formed in the previous lift.

For rapid construction of a constant-thickness wall, a continuously rising form, commonly known as a sliding shutter is used. The shutter may rise at the rate of 150 to 300mm per hour depending upon the rate of hardening of concrete. Wither a hydraulic jack or a manually operated screw jack may be used for raising the form.

Also, read: 11 Types Of Bonds In Brick Masonry Wall Construction

FAQs:

Q: What should be the vertical height of the shuttering for columns or walls?

Ans: The vertical height of the shuttering used in columns and walls should not be more than 1.5m for the vertical drop of the concrete at a time. However, if the shuttering for columns and walls exceeds 3.5m, the props may be provided in multi-stages. Before the concreting is started, the props and wedges shall be thoroughly checked to see that these are intact and take suitable action in case they are loose.

Q: What is the most common formwork for concrete?

Ans: The most common formwork for concrete is timber formwork as it is readily available and easy to handle. Also, it is commonly used for most of the concrete members of the structure.

References:

- Punima, Dr. B. C., Jain, Er. A. K., & Jain, Dr. A. K. (2023). Building Construction (12th ed.). Luxmi Publication (P) Limited. https://www.laxmipublications.com/servlet/lpgetbiblio?bno=000200&pageName=Keywords

- Chudley, R., & Greeno, R. (2014). Building Construction Hand Book (10th ed.). Taylor & Francis Books.

![]()