In general, there are two basic types of road, namely flexible pavement and rigid pavement. Either of the pavements can be built using different materials, including asphalt, concrete, and WBM (water-bound macadam), each offering distinct advantages and suitability for specific conditions. This article provides a comprehensive exploration of the WBM road, exploring its specifications and construction techniques.

As we know roads are vital infrastructural elements that serve as essential pathways for transportation and connect various destinations, enabling the movement of people, goods, and vehicles. They play a crucial role in facilitating economic growth, trade, and social interactions within communities. Roads can vary in size, design, and purpose, ranging from local streets and residential roads to highways and expressways. This article will help you understand which material is best for building roads: concrete (which is strong and long-lasting), asphalt (which is smooth and flexible), or WBM (which is cost-effective and suitable for certain areas).

What is Water Bound Macadam (WBM)?

Water Bound Macadam (WBM) was introduced by Scottish civil engineer John Loudon McAdam (1756-1836), and the name “macadam” is derived from his surname. McAdam revolutionized road construction in the early 19th century with his innovative approach. His new road concept of road construction became known by the year 1827, (Khanna & Justo, 2009. p12). It consists of multiple layers of compacted crushed stones or aggregates, bound together by a combination of stone dust and water.

The present-day macadam means, the pavement base course made of crushed or broken aggregate mechanically interlocked by rolling and the voids are filled with screening and binding materials with the assistance of water. The WBM may be used as a sub-base, base course or surface course.

What is WBM Road?

WBM road is a flexible road built using the water-bound macadam method. These types of roads are typically constructed in areas where there is low traffic volume or in rural areas where the road users are minimal. They are also constructed when the budget for constructing concrete and asphalt roads is inadequate and serviced as alternative roads for shorter periods.

However, WBM roads are known for their durability if periodic maintenance is carried out. The main issues associated with such road is the wearing of aggregate and washing off stone dust due to heavy surface runoff.

WBM Road Specifications

Below are the typical specifications for constructing WBM roads:

Subgrade Preparation: The subgrade, which is the natural soil or compacted layer upon which the road will be constructed, should be properly prepared by removing any loose or unsuitable material. The subgrade should be adequately compacted to provide a stable foundation.

Aggregate Material: The aggregate used in WBM road construction is the main component. It typically consists of hard and durable stones, crushed rock, gravel, or a mixture of these materials. The aggregate should be well-graded, free from organic matter, and have sufficient strength to withstand traffic loads.

Grading: The aggregate used in WBM should be graded properly to ensure optimal interlocking of particles, resulting in a stable road surface. The grading is usually specified in terms of percentages passing through various sieve sizes.

Particle Size: The coarse aggregates used in WBM are generally larger, while the screenings (filler material) are smaller particles that fill the voids between the larger aggregates after compaction.

Compaction: During construction, the aggregates are compacted thoroughly using rollers or other compaction equipment to achieve a dense and solid structure.

Watering: Water is an essential component of WBM road construction. Proper watering is done during compaction to aid in achieving maximum density and bond between the particles.

Surface Finish: After compaction, the surface is made smooth and uniform to ensure safe and comfortable driving conditions.

Thickness: The thickness of the WBM layer varies based on the traffic load and the design specifications. It is typically around 100 to 150 mm for rural roads and can be thicker for high-traffic areas.

Drainage: Adequate drainage provisions should be made to ensure that water does not accumulate on the road surface, as this can weaken the structure and cause damage.

Quality Control: Regular quality control checks should be performed during the construction process to ensure that the materials used and the construction methods adhere to the specified standards.

Materials for Water Bound Macadam Road Construction

Course Aggregates

The coarse aggregates utilized in the construction of WBM should be composed of clean, crushed or broken stone, crushed slag, over-burnt brick (Jhama) metal, or naturally occurring aggregates like kankar and laterite. These aggregates must meet the specified quality requirements as described below. It is generally advisable to limit the use of crushable type aggregates to the lower layers of the pavement.

Crushed or Broken Stone

The crushed or broken stone used must possess qualities of hardness, durability, and freedom from flat, elongated, soft, and disintegrated particles. Additionally, it should be devoid of dirt or any other harmful materials that may compromise its quality.

Crushed Slag

The hard crushed slag shall be used from air-cooled blast furnace slag which is angular in shape and uniform in quality and density.

Overburnt brick metal

Overburnt brick metal and brickbats which are free from dust and other deleterious materials shall be used.

| Grading Number | Size Range (mm) | Sieve Size | Percentage By Weight Passing The Seive |

|---|---|---|---|

| 1 | 90 to 40 | 100 | 100 |

| 80 | 65-85 | ||

| 63 | 25-60 | ||

| 40 | 0-15 | ||

| 20 | 0-5 | ||

| 2 | 63 to 40 | 80 | 100 |

| 63 | 90-100 | ||

| 50 | 35-70 | ||

| 40 | 0-15 | ||

| 20 | 0-5 | ||

| 3 | 50 to 20 | 63 | 100 |

| 50 | 95-100 | ||

| 40 | 35-70 | ||

| 20 | 0-10 | ||

| 10 | 0-5 |

| S.No. | Properties | Requirements For Pavement Layers (Maximum Percentage) | ||

|---|---|---|---|---|

| Sub-base Course | Base Course | Surface Course | ||

| 1. | Los Angeles Abrasion Value | 60 | 50 | 40 |

| 2. | Aggregate Impact value | 50 | 40 | 30 |

| 3. | Flakiness Index | – | 15 | 15 |

Filler Material in Road Construction (Screenings):

Filler material, known as screenings, plays a vital role in WBM (Water Bound Macadam) road construction by filling the gaps between compacted aggregate particles. These screening materials are generally smaller in size compared to the coarse aggregate used in the construction process.

The table below displays the standard grading specifications for screenings required in the construction of WBM Roads. To minimize the overall cost of WBM roads, the IRC (Indian Road Congress) recommends the use of non-plastic materials like kankar, murram, or gravel as alternatives to screenings.

| Grading Classification | Size Of Screening (Mm) | Sieve Size (Mm) | Percentage By Weight Passing The Sieve |

|---|---|---|---|

| A | 12.5 | 12.5 | 100 |

| 10 | 90-100 | ||

| 4.75 | 10-30 | ||

| 0.15 | 0-8 | ||

| B | 10 | 10 | 100 |

| 4.75 | 85-100 | ||

| 0.15 | 10-30 |

Also, read: Wet Mix Macadam: Materials | Specification | Construction Process

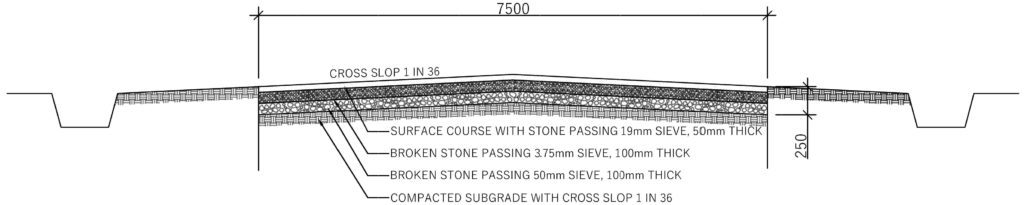

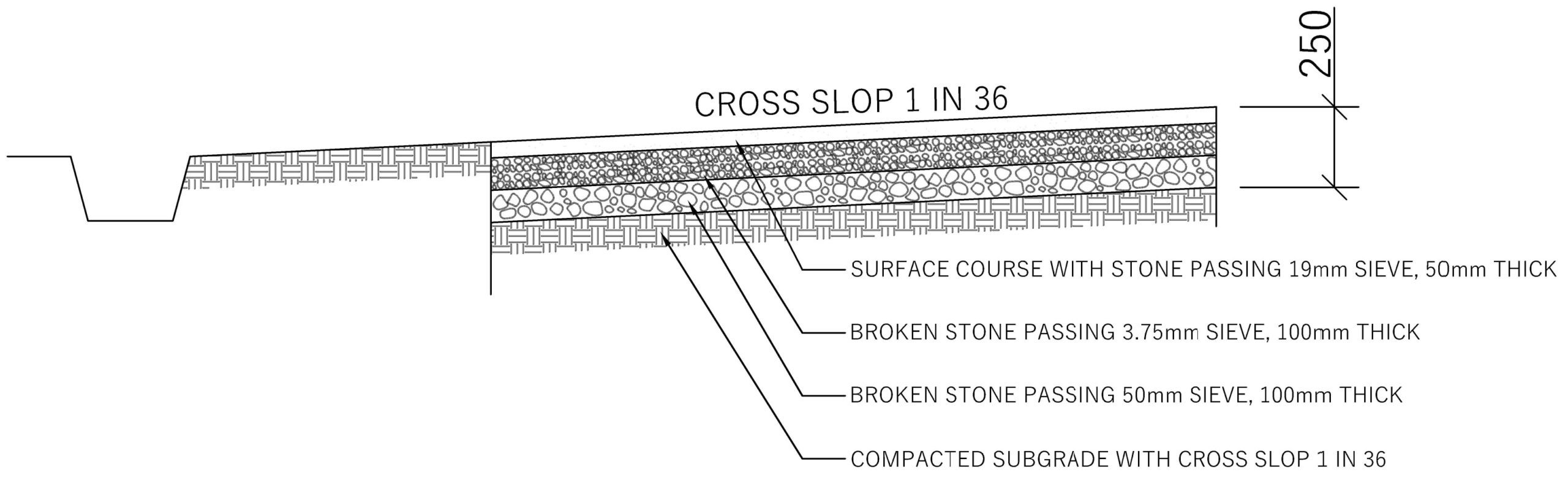

WBM Road Cross-Section

- Subgrade: The natural soil or compacted earth beneath the road surface. It provides a stable foundation for the road.

- Sub-base: A layer of coarse aggregates placed on top of the subgrade. It helps in distributing the load and providing additional stability to the road.

- Base course: This layer consists of crushed stones or aggregates of specific sizes. It is compacted and provides a strong base for the road surface.

- Wearing course: The topmost layer of the road, also known as the surface layer. It is made up of finer aggregates and stone dust. This layer is carefully compacted to form a smooth and durable surface for vehicles to travel on.

Also, read: What is Rigid Pavement? | 4 Types of Rigid Pavement.

Construction Procedure for WBM Road

The construction process involves spreading the aggregates in layers and compacting them using a roller or compactor. Once the aggregates are compacted, water is sprinkled over the surface, and stone dust is applied to fill the voids between the aggregates. The water and stone dust combination helps to bind the aggregates together, forming a solid and stable road surface. The process involved in construction is as follows:

Provision of Lateral Confinement of Aggregates

To ensure lateral confinement, the road shoulders are constructed with the same thickness as the compacted WBM road. The purpose of building the road shoulders is to create vertical edges that contain the subsequent road surface between them, facilitating the application of the coarse mixture.

Spreading Of Coarse Aggregates Or Mixtures

Once the road shoulders are in place, a coarse combination of aggregates is uniformly spread over the prepared base. The thickness and number of layers of the WBM road are determined by the pavement design requirements. Typically, a single compressed layer measuring 75 mm in thickness is considered adequate, while special roads may have two layers of 150 mm each.

Rolling

After the aggregates have been evenly spread, they are compacted using a vibrating or three-wheeled road roller. The proper execution of rolling is crucial for a durable WBM road, requiring skilled workers to prevent errors that could lead to surface irregularities or premature wear.

Screening

The screening process involves passing the base course material through a series of screens or sieves with varying sizes. This separates the material into different size fractions while removing any unwanted debris or particles. The resulting material is then graded and sorted to meet the specified requirements for the WBM road construction project.

Sprinkling and grouting

Once the screening process is complete, the upper surface of the WBM road is swept, wetted, and rolled. Water is sprinkled over the surface, and wet screening material is applied to the additional area using a broom.

Surface drying

After the final rolling, the newly constructed road is allowed to dry and set overnight. If any additional area is still visible the next day, sufficient screening material is applied to ensure a uniform surface.

Preparing the road shoulders

The soil is compacted and shaped to the required cross slope to properly form and prepare the road shoulders.

Opening to traffic

Once the freshly constructed road has dried and any depressions have been addressed, it is considered complete. Barricades are placed to guide and distribute traffic evenly on the road, with lengthwise drums acting as barriers.

Also, read: 12 Types of cracks in asphalt pavement | Symptoms | Causes | Treatment of defects

Share You Thoughts

What are the filler material used in road construction in your country or region?

Let us know your experience in the comments below!

FAQs:

Q: When is the WBM road constructed?

Answer: WBM road is constructed in an area where the traffic volume is low and when there is no adequate budget to construct asphalt and concrete roads.

Q: What should the thickness of the WBM road be?

Answer: The thickness of the WBM road will depend upon the design consideration, however, it is usually between 75 to 150mm thick.

Q: Why WBM roads are not preferred over bituminous surfaced roads?

Answer: When WBM is used as a surface course for the road, it deteriorates rapidly under adverse conditions of traffic and weather, whereas bituminous surfaced roads have longer durability and service life thus bituminous surface roads are preferred over WBM surfaced roads.

References:

- IRC:19-2005.(3rd revision). Standard Specifications and Code of Practice for Water Bound Macadam. The Indian Road Congress. Kama Koti Marg. New Delhi-110022

- Khanna, S.K., & Justo, C.E.G. (1971). Highway Engineering (8th ed). Roorkee (U.A.): Nem Chand & Bros.

- John Loudon McAdam. (2023, May 13). In Wikipedia. https://en.wikipedia.org/wiki/John_Loudon_McAdam

- Housing News. (2023). What is WBM road and how is it constructed? Housing News. https://housing.com/news/wbm-road/#FAQs

![]()